Flanged Ball Slewing Bearings Compact Power for Rotational Systems

What is Flanged Ball Slewing Bearings

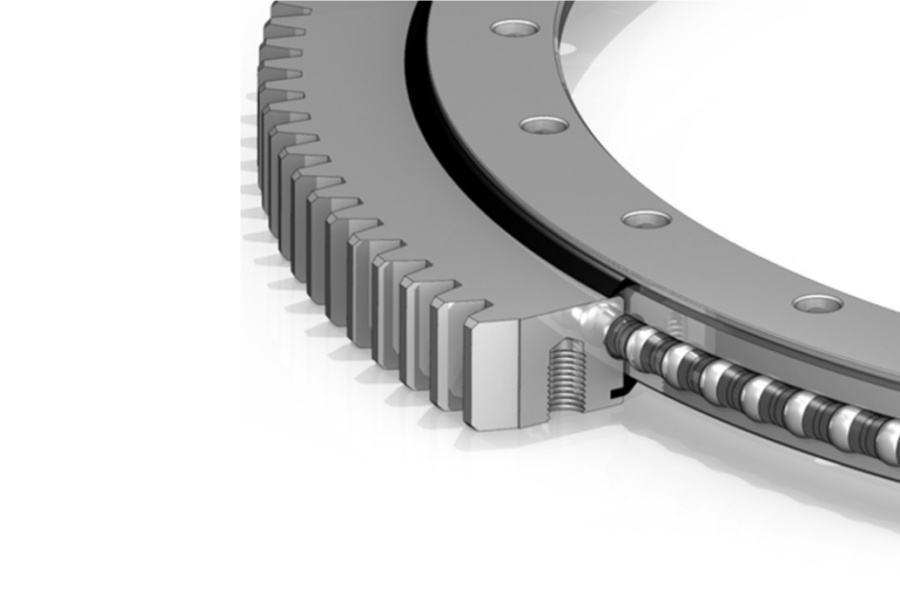

Flanged Ball Slewing Bearings are specialized rotational components featuring integrated mounting flanges that enable direct structural attachment while utilizing ball-bearing elements to handle combined axial, radial, and moment loads. These bearings consist of hardened inner/outer rings, precision balls, and retention systems (cages or spacers), with their defining L-shaped flanges eliminating separate adapter plates. Engineered for applications requiring secure mounting in space-constrained environments, they provide smooth rotation under heavy loads in equipment ranging from construction machinery to renewable energy systems.

Enhancing Gear Machining Efficiency in Slewing Bearings

Optimizing gear manufacturing processes reduces production costs while maintaining critical performance standards:

Combined Roughing/Finishing Strategies

Implement high-feed milling for rapid material removal during roughing stages followed by precision grinding for final tooth geometry, reducing machining time by 30-40%

Advanced Tooling Solutions

Utilize coated carbide inserts with optimized chipbreakers for hobbing, and CBN/Ceramic wheels for grinding, enabling 25% faster cutting speeds without compromising surface integrity

Automated Process Chains

Integrate robotic part handling between machining centers and gear grinders to eliminate manual intervention, reducing processing time by 50%

Adaptive Machining Paths

Implement AI-driven toolpath optimization that adjusts feed rates dynamically based on cutting resistance, minimizing idle time while preventing tool deflection

Virtual Process Simulation

Leverage digital twin technology to predict and correct potential distortions before heat treatment, reducing post-hardening correction grinding by up to 60%

Laser-Assisted Machining

Apply localized preheating during cutting of hardened steels, decreasing cutting forces by 35% and extending tool life 3x

Characteristics of Flanged Ball Slewing Bearings

These bearings deliver unique advantages through specialized engineering:

Integrated Flange Geometry

L-shaped ring profiles provide direct bolting surfaces that enhance structural rigidity while reducing assembly components by 70%

Multi-Directional Load Capacity

Single-row designs handle combined loads up to 1.5x their nominal rating through optimized raceway-ball contact angles

Precision-Ground Raceways

Hardened surfaces (HRC 58-62) finished to Ra 0.2μm ensure smooth operation with starting torque below 2% of rated capacity

Space-Optimized Design

Compact axial profiles up to 40% slimmer than standard slewing rings enable installation in confined spaces

Advanced Sealing Systems

Triple-labyrinth seals with HNBR/FKM lips maintain IP66 protection across -40°C to +120°C operating range

Material Versatility

Options from forged 42CrMo4 (high-load) to electroslag-remelted 100Cr6 (high-speed) for application-specific performance

Configuration Flexibility

Four mounting variants: Double-flanged, inner-gear outer-flange, outer-gear inner-flange, and double-external-flange

Applications of Flanged Ball Slewing Bearings

Critical rotation solutions across industries:

Wind Energy

Yaw/pitch systems in turbines ≤5MW capacity with 25-year design life

Material Handling

Automated storage/retrieval systems requiring ≤0.1° positioning accuracy

Medical Technology

CT/MRI gantry rotation with EMI-compliant designs

Construction Machinery

Compact excavator swing systems (≤15t class)

Precision Manufacturing

Welding positioners with ≤5 arc-min runout tolerance

Aerospace

Satellite antenna positioning for LEO/GEO systems

Transportation

Fifth-wheel turntables handling 40-tonne GVW

Pricing Determinants for Flanged Ball Slewing Bearings

Cost drivers reflect technical complexity:

Material Selection

Forged 42CrMo4 alloys cost 2.3x more than cast G42CrMo4 equivalents

Precision Requirements

DIN Class 6 gear grinding adds 35% cost versus Class 10 milling

Heat Treatment Depth

5mm hardened case depth increases processing time 80% over standard 2.5mm

Sealing Complexity

Multi-lip fluorocarbon seals cost 4x standard NBR single-lip designs

Certification Compliance

DNV-GL/CE certifications add 15-22% to base price

Lot Sizes

Production runs <50 units incur 30% surcharge versus 500+ quantities

Gear Specifications

Ground internal gears add 25% cost premium over external gears

Flanged Ball Slewing Bearings Supplier

LYRADRIVE manufactures precision Flanged Ball Slewing Bearings using forged alloy steels and advanced grinding technology, achieving ≤0.005mm raceway roundness tolerances. The company provides application-specific configurations with 2.5-5mm case-hardened surfaces (HRC 58+), supporting axial loads to 4,800kN. LYRADRIVE's integrated flange designs reduce installation time by 60% while maintaining IP66 sealing integrity across extreme temperature ranges. Custom engineering services include digital twin simulations for load optimization.