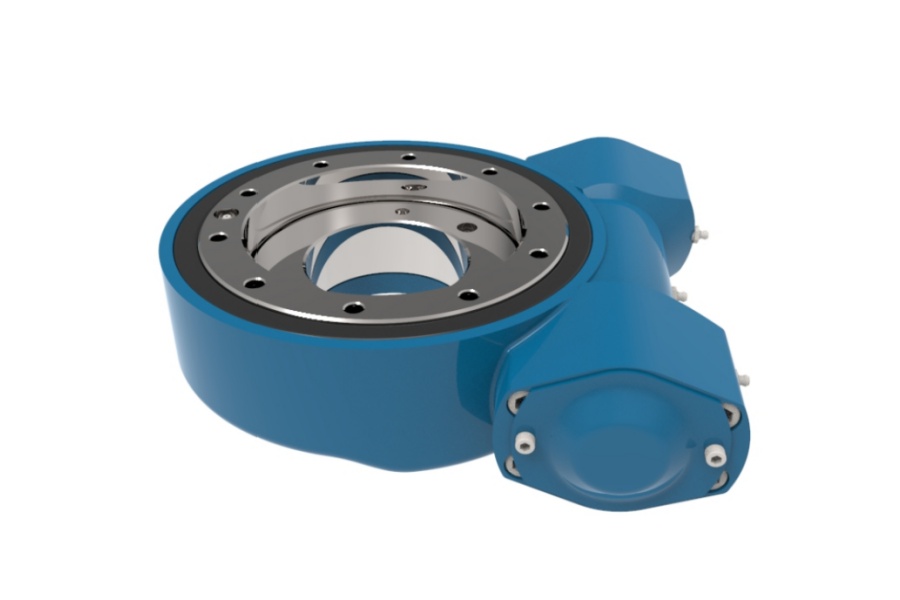

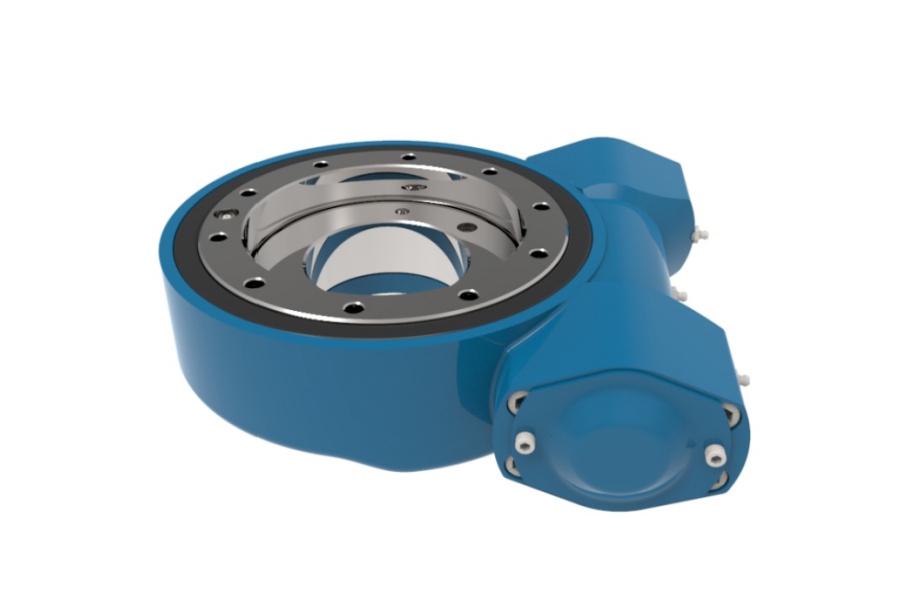

Worm Gear Drive WE7 for Demanding Industrial Applications

What is Worm Gear Drive WE7

Worm Gear Drive WE7 is a highly engineered slewing drive solution integrating a robust housing, precision worm, and hardened worm gear into a single compact assembly. Engineered for severe-duty applications, it excels in scenarios demanding substantial torque output, precise positioning, and unwavering reliability under significant axial, radial, and moment loads. This integrated design eliminates the need for complex mounting arrangements, providing a ready-to-install unit protected by a rugged enclosure. The WE7 series, including enhanced variants WEA7 and WEB7, is specifically optimized for challenging environments and critical operations across diverse industries.

Advantages of Using Slewing Drives with Planetary Gearboxes

Slewing drives incorporating planetary gearboxes offer distinct benefits in many motion control applications. Planetary systems deliver exceptionally high torque density relative to their size, allowing for compact drive solutions capable of handling substantial loads. They achieve high efficiency across multiple gear stages, minimizing power loss and heat generation, particularly beneficial in continuous operation. Planetary gears provide excellent load distribution across multiple planet gears, reducing stress on individual components and enhancing overall longevity and reliability. This configuration also offers inherent rigidity, crucial for maintaining precise positioning under load and resisting backlash. Furthermore, planetary systems often provide smoother operation at higher input speeds compared to some alternatives. While worm gear drives like the WE7 offer unique advantages such as self-locking and simplicity in lower-speed applications, planetary slewing drives are often preferred where high input speeds, maximum efficiency, or the smallest possible footprint for a given torque are paramount requirements.

Key Features of Worm Gear Drive WE7

The WE7 series distinguishes itself through an array of robust engineering features designed for peak performance and longevity. Its Integrated Compact Design consolidates the base, worm, and worm gear within a single, sturdy housing. This simplifies installation, minimizes potential misalignment issues, reduces the overall system footprint, and streamlines maintenance procedures. Engineered for Exceptional Load Capacity, the WE7 simultaneously handles significant forces: static axial loads up to 220 kN, static radial loads up to 90 kN, dynamic axial loads up to 63 kN, dynamic radial loads up to 48 kN, an output torque of 3.5 kN.m, a tilting moment of 14.2 kN.m, and a substantial holding torque of 20 kN.m. This multi-load capability ensures stability and reliability in the most demanding scenarios.

High Efficiency and Meshing Performance is achieved through the use of optimized ZA or ZK worm tooth profiles interacting with precision-machined worm gears. This design maximizes contact area and minimizes friction, leading to improved torque transmission and overall operational efficiency. A critical safety feature is its Inherent Self-Locking Capability. The fundamental geometry of the worm and worm gear interface prevents back-driving when input power is removed, ensuring the driven load remains securely locked in position without requiring additional braking systems. This is vital for safety in applications like lifting or positioning.

For operation in harsh conditions, the WE7 boasts Superior Environmental Protection, typically rated at IP65. This seals the unit effectively against dust ingress and low-pressure water jets, making it suitable for outdoor use, dusty industrial settings, or environments with washdown requirements. Offering Flexible Drive Options, the WE7 seamlessly interfaces with various prime movers. It readily accommodates hydraulic motors for applications demanding high power density and variable speed control or electric motors (including standard AC, DC, or servo motors) for precise positioning and automation integration, providing significant application versatility.

Worm Gear Drive WE7 Applications

The robust design and versatile capabilities of the WE7 series make it indispensable across numerous demanding industrial sectors. In Aerial Work Platforms (AWPs), it serves as a critical slewing drive for the turntable, providing the smooth, controlled rotation essential for operator safety and precise platform positioning at height. Its self-locking feature is particularly crucial here. The mining and construction industries leverage the WE7 in Mining and Drilling Equipment, where it powers rock drill rotation and provides the high-torque drive for lifting mechanisms. Its ability to withstand shock loads and operate reliably in abrasive, dirty environments is paramount.

For Industrial Automation and Material Handling, the WE7 excels in Positioning Drives for robotic arms, indexing tables, welding positioners, and assembly line fixtures, offering the required precision (≤0.15° tracking accuracy) and holding power. It is also widely used in Tilting and Flipping Drives for foundry equipment, furnaces, heavy-duty material handling clamps, and dump mechanisms, where its high moment load capacity is essential. Renewable Energy applications, such as solar tracker azimuth drives (particularly in smaller to medium-sized trackers or harsh environments), benefit from its robustness and self-locking capability. Additionally, it finds use in specialized Heavy-Duty Machinery like crane jibs, winch drives, military equipment turrets, and stage machinery, wherever compact size, high torque, and reliable motion control are required.

Factors Influencing Worm Gear Drive WE7 Price

The cost of a Worm Gear Drive WE7 unit is determined by several key factors. The primary determinant is the specific Gear Ratio selected. While the standard ratio is 47:1, offering the torque specifications listed, custom ratios may be available, impacting manufacturing complexity and cost. The choice of Materials and Manufacturing Precision significantly affects price. High-quality alloy steels for worms and gears, specialized bronze alloys for worm wheels, advanced heat treatment processes (like case hardening), and the precision grinding required for optimal meshing and efficiency (especially for ZA/ZK profiles) all contribute to component cost. Higher precision grades demand more rigorous manufacturing and quality control.

Sealing and Protection Requirements play a role. The standard IP65 sealing is robust, but applications needing enhanced sealing (like the WEA7/WEB7 variants with double-lip seals for extreme dust/mud environments) will incur a higher cost. The Type and Specifications of the Integrated Bearing System within the slewing ring are crucial for handling the specified loads and moments; larger or higher-capacity bearings increase cost. Drive Input Options also influence price. Units supplied without a motor offer a base price, while those pre-coupled with hydraulic or specific electric motors (especially high-efficiency or servo types) will see a significant price increase reflecting the motor cost and integration work.

Order Quantity and Customization are major factors. Larger volume orders typically benefit from economies of scale, reducing the unit price. Conversely, any customization – such as special mounting flanges, shaft modifications, unique sealing arrangements, non-standard paint, or special lubrication requirements – adds engineering and manufacturing costs. Finally, the Supplier's Value-Added Services, including extensive technical support during selection and integration, comprehensive warranty coverage, reliable after-sales service, and efficient logistics, are reflected in the overall pricing structure. While potentially increasing the initial cost compared to a basic supplier, these services often provide significant long-term value and reduced total cost of ownership.

Reliable Supplier of Worm Gear Drive WE7

LYRADRIVE stands as a leading manufacturer and trusted global supplier of high-performance slewing drives, including the robust WE7 series. With a strong commitment to engineering excellence and quality manufacturing, LYRADRIVE specializes in producing integrated drive solutions designed to meet the rigorous demands of heavy industry. They offer the standard WE7 alongside the enhanced WEA7 and WEB7 models featuring superior sealing for extreme environments. LYRADRIVE provides comprehensive technical support, assisting customers in selecting the optimal drive configuration for their specific application requirements, whether involving standard specifications or customized solutions. Their focus extends beyond just product supply, encompassing reliable delivery, responsive customer service, and ensuring the WE7 drive delivers maximum operational lifespan and reliability under challenging conditions.