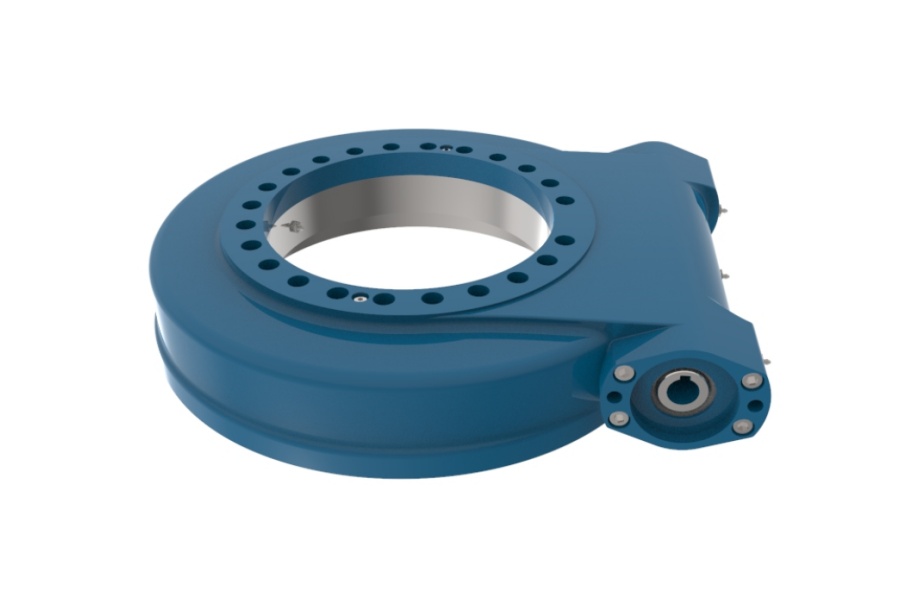

WE14 Worm Gear Drive Gigaton Load Precision Engineering

What is Worm Gear Drive WE14

Worm Gear Drive WE14 is a mega-capacity integrated slewing drive engineered for extreme-load precision applications. It combines a double-ground alloy steel worm, induction-hardened bronze worm wheel with ZK tooth profiles, and a reinforced four-point contact slewing bearing within a rigid, ribbed housing. Engineered to withstand colossal forces – 960 kN static axial loads, 360 kN static radial loads, 230 kN dynamic axial loads, and 200 kN dynamic radial loads – the WE14 delivers 10.8 kN.m output torque, resists 71.2 kN.m tilting moments, and provides 48 kN.m holding torque. Its IP66-rated architecture features triple labyrinth seals while offering inherent mechanical self-locking through a 3.5° lead angle design.

Why Quench-Fractured Worm Teeth Should Not Be Repaired

Attempting to repair fracture-damaged quenched teeth compromises drive integrity due to three fundamental reasons:

Material Metallurgy Disruption:

Case hardening creates a 0.8-1.2mm deep surface layer (62-64 HRC) with compressive residual stresses

Welding repairs anneal hardened zones, reducing hardness to <45 HRC (60% strength loss)

Crack Propagation Risk:

Quench fractures originate from subsurface inclusions (MnS, Al₂O₃)

Repair masks root cracks propagating beyond ASTM E399 Kᴵᶜ thresholds

Distortion & Stress Concentration:

Localized heat input during welding induces micro-warping (>0.05mm/mm)

Grinding repair creates stress risers at tooth root fillets (theoretical stress concentration factor Kt≥2.8)

WE14 prevents such failures through vacuum degassed steel (O₂<15ppm), controlled quenching (martensite transformation >95%), and 100% MPI inspection per ISO 4986.

Key Features of Worm Gear Drive WE14

Gigaton Load Capacity: Engineered for infrastructure-scale loads, handles 960 kN axial forces (equivalent to 98 vertical tonnes) plus 360 kN radial loads and 71.2 kN.m tilting moments.

Ultra-Precision Motion: ≤0.1° tracking accuracy achieved through CNC profile grinding (DIN Class 10) and preloaded crossed-roller bearings. Maintains precision under full 10.8 kN.m torque.

Absolute Self-Locking: 3.5° lead angle creates geometric irreversibility, mechanically securing 48 kN.m loads without brakes. Exceeds ISO 14122 safety factors.

Extreme Environment Defense: Triple-lip seals + labyrinth barriers + IP66 rating resist pressurized steam, quarry slurry, and coastal salt spray. WEA14/WEB14 offer corrosion-resistant coatings.

Advanced Thermal Management: Helical cooling fins increase heat dissipation by 40%, maintaining oil viscosity at sustained 86:1 ratio operation.

Drive Flexibility: Direct mounting for hydraulic motors (350+ bar) or IEC 225mm frame motors (servo-ready).

Power Density Champion: Generates 10.8 kN.m torque from 75 kg mass – 144 Nm/kg ratio outperforms hydraulic rotary actuators.

Worm Gear Drive WE14 Applications

Hydroelectric Plant Systems: Spillway gate positioning and turbine maintenance cranes. 960 kN axial capacity handles water thrust forces; self-locking prevents gate drift.

Mining Super-Loaders: Bucket wheel excavator slewing (10,000+ tonne/hour). Resists abrasive ore impact; IP66 seals exclude silica dust.

Shipyard Mega-Cranes: Goliath crane rotation for hull assembly. 48 kN.m holding torque secures 500+ tonne loads in marine environments.

Nuclear Facility Handling: Fuel rod manipulator drives. ≤0.1° accuracy meets nuclear regulatory positioning requirements.

Dam Construction Equipment: Caisson positioning systems. Withstands 230 kN dynamic axial loads during immersion.

Telescope Mounts: Radio telescope azimuth drives. Micron-level smoothness enables sub-arcsecond tracking.

Heavy Press Manufacturing: 80,000 kN forging press ejection systems. Maintains alignment under cyclic shock loads.

Factors Influencing Worm Gear Drive WE14 Price

Material Excellence: Vacuum arc remelted steel worms (+28% cost) and nickel-aluminum bronze wheels (+22%) enable 10⁷ load cycles.

Precision Manufacturing:

Double grinding (rough + finish) adds 35% cost

DIN Class 10 accuracy requires 0.8μm Ra finishing

100% coordinate measuring machine (CMM) inspection

Sealing Hierarchy:

IP66 standard: baseline cost

IP69K (WEB14): +18%

Pressurized oil purge systems: +32%

Bearing Systems:

Crossed-roller bearings: standard

Custom three-row roller configuration: +40%

Certifications:

ASME B30.2 (overhead cranes): +15%

Lloyd's Register marine approval: +12%

ATEX Zone 1: +25%

Ratio Customization: 86:1 standard; non-standard ratios (e.g., 120:1) require new hobs (+30%).

Volume Economics: 40+ unit orders reduce cost 30% via batch hardening optimization.

Global Engineering Partner for Worm Gear Drive WE14

LYRADRIVE delivers mission-critical slewing solutions for extreme environments, manufacturing the WE14 series to aerospace-grade tolerances. Their vertically integrated production controls material metallurgy and heat treatment, offering WE14, WEA14 (corrosion-resistant), and WEB14 (IP69K) variants. Engineering support includes FEA-based load validation and lifecycle simulation. With ISO 17025-accredited testing and global service hubs, LYRADRIVE ensures operational integrity where failure is not an option.