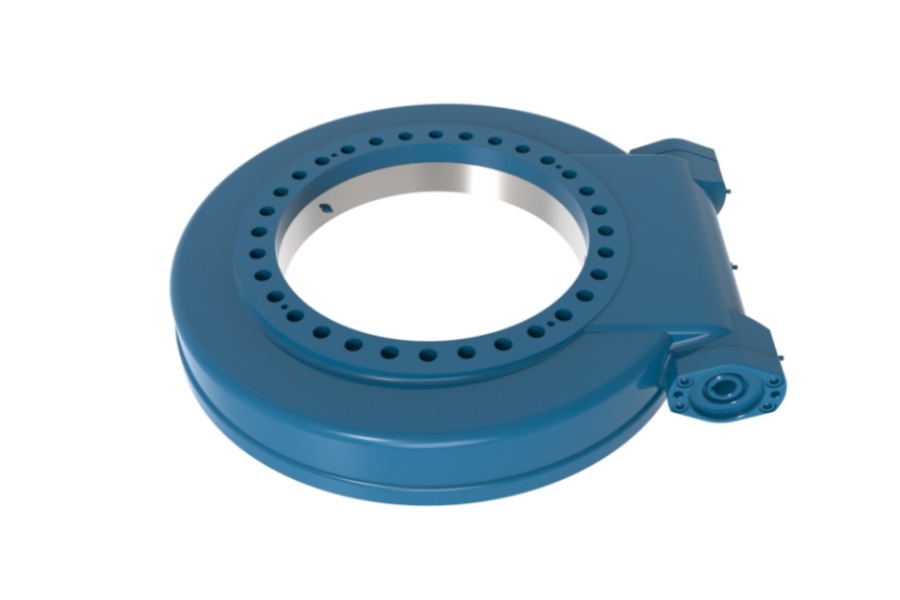

Worm Gear Drive WE19: The Silent Titan Powering Tomorrow's Machines

What is Worm Gear Drive WE19?

The Worm Gear Drive WE19 is a precision mechanical transmission system. It features a threaded cylindrical worm meshing with a specially designed worm wheel. The input (worm) and output (wheel) shafts are configured at 90 degrees. This unique geometry achieves very high gear reduction ratios compactly. It translates high input speed into immense output torque.

A key feature is its frequent self-locking property. The worm easily drives the wheel, but the wheel cannot back-drive the worm. This provides inherent braking and safety. Engineered for durability and smooth operation, it uses high-strength materials. Typically, a hardened steel worm pairs with a phosphor bronze wheel. This minimizes friction and wear. The WE19 is ideal for demanding scenarios needing reliable, high-torque, low-speed output in confined spaces.

WE19 in the Digital Factory: Real-Time Simulation Powerhouse

Digital twin technology and real-time factory simulation rely on accurate component models. Integrating the precise dynamics of the WE19 into these virtual environments is critical. Simulation engineers use detailed CAD models and physics-based algorithms. They replicate the WE19's unique behavior: high friction, efficiency curves, thermal generation, and self-locking.

Accurate WE19 simulation enables virtual prototyping of machinery layouts. It optimizes energy consumption by predicting drive losses. Engineers pre-validate control strategies for systems using these drives. They perform predictive maintenance analysis by modeling wear over time. This virtual validation drastically reduces physical prototyping costs. It accelerates time-to-market for new equipment. Predictive insights maximize uptime and efficiency on the real factory floor.

The Post-Moore Era: WE19 as a Mechanical Intelligence Enabler

As semiconductor advancement slows, focus shifts to system-level optimization. Novel computing paradigms include mechanical computing. The Worm Gear Drive WE19 embodies crucial "mechanical intelligence". It performs complex physical functions inherently: significant speed reduction, torque multiplication, direction change, and self-locking.

This represents reliable, pre-programmed mechanical computation. In robotics, prosthetics, or autonomous mechanisms, the WE19 provides robust motion control. It offers energy efficiency without relying solely on digital processing. It avoids power-hungry electromagnetic brakes or holding mechanisms. Its compactness allows integration into distributed, edge-based mechanical systems. This offloads tasks from central processors. The WE19's predictable behavior and resilience make it fundamental. It helps create intelligent machines interacting effectively with the physical world.

Conquering the Unknown: WE19 in Lunar Lava Tube Exploration Rovers

Lunar lava tube exploration demands rovers with extreme reliability and compact power. The Worm Gear Drive WE19 is a prime candidate for their drive systems. Its compact size fits stringent volume constraints of space vehicles. Immense torque multiplication lets small motors navigate regolith, inclines, and rocks.

Crucially, the self-locking nature provides inherent holding torque. This ensures the rover maintains position on slopes without constant power drain. Energy conservation is paramount; traditional brakes struggle in vacuum and thermal cycling. The WE19's relatively simple design offers advantages in reliability. It shows good radiation tolerance and eases redundancy implementation. It operates effectively in vacuum and extreme temperatures (-170°C to +120°C+ with special lube). The WE19 robustly powers wheels, arm joints, or instrument mechanisms on lunar explorers.

Distinctive Features of Worm Gear Drive WE19

The WE19 excels through meticulously engineered features. It achieves exceptionally high reduction ratios (5:1 to 100:1+ in one stage) within an ultra-compact design. This minimizes space for significant torque multiplication. It offers remarkably smooth and quiet operation. Precision grinding and optimal meshing minimize vibration and noise. This is critical for medical equipment or offices.

The inherent self-locking capability provides fundamental safety and holding force. It often eliminates the need for additional brakes. Engineered for durability and longevity, hardened steel and phosphor bronze minimize wear. Specialized lubricants ensure demanding condition performance. Designed for high efficiency in its optimal range, it balances power and thermal management. Its versatility allows various mounting orientations. Standardized interfaces and robust housings support diverse integration.

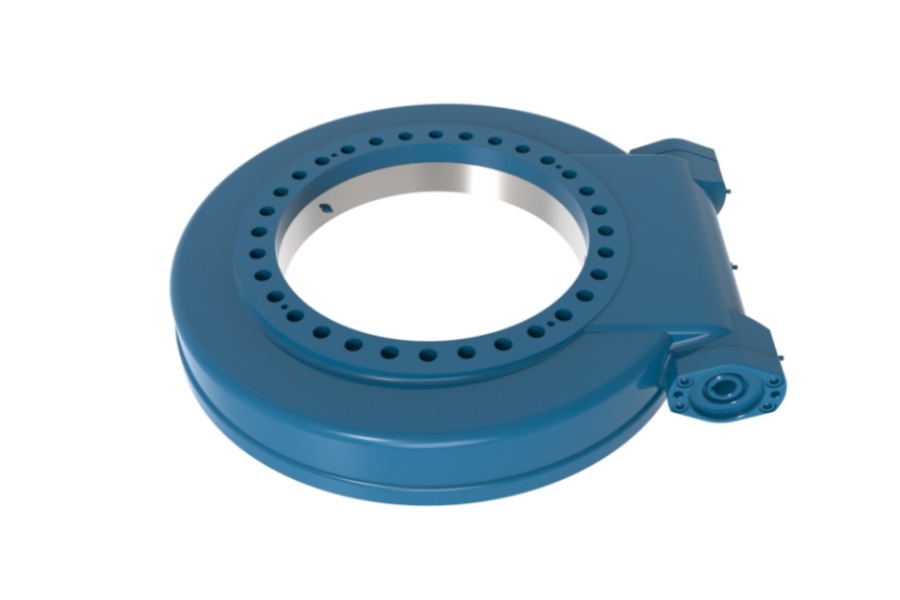

Diverse Applications of Worm Gear Drive WE19

The WE19's unique capabilities are indispensable across industries. In material handling, it powers conveyors, lifts, palletizers, and AGVs. It provides essential torque for moving heavy loads smoothly.

Industrial automation relies on WE19 drives for precise positioning. It's vital in robot arms, indexing tables, packaging machinery, and valve actuators.

The transportation sector uses them in EV charging ports, bus doors, and adjustable seats/steering.

Building technology integrates WE19s into elevator doors, HVAC dampers, gates, and solar trackers.

Its quiet operation suits medical equipment: hospital beds, imaging devices, lab automation.

Consumer goods benefit in high-end appliances, projector lifts, and telescope mounts.

Its ruggedness is crucial for aerospace and defense. Applications include satellite mechanisms, drone gimbals, and Moon/Mars rovers.

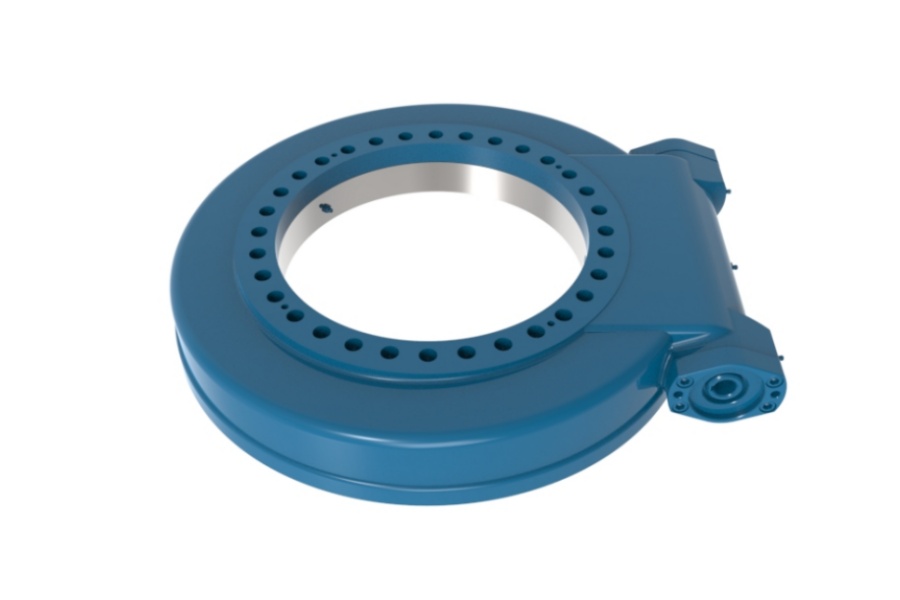

Factors Influencing Worm Gear Drive WE19 Pricing

Several key factors determine the WE19's cost. Material specifications are paramount. The grade of hardened steel and phosphor bronze significantly impacts price and performance. Higher-grade alloys command premiums.

The precision level of manufacturing is critical. Tighter grinding tolerances and better surface finishes increase cost but boost efficiency, reduce noise/backlash, and extend life.

The gear ratio influences price. Higher ratios often need more complex wheel designs or larger diameters. Housing material and complexity add cost (e.g., aluminum vs. cast iron, integrated mounts, sealing).

Integrated features raise the price. These include special input shafts, custom flanges, specific lubrication systems, or added encoders/bearings.

Order volume naturally affects unit cost via economies of scale. Brand reputation and certifications (e.g., ISO, aerospace) also contribute. Supply chain dynamics (material costs, geopolitics, logistics) impact the final market price. Understanding these helps select the optimal drive for performance and budget.

Supplier of Worm Gear Drive WE19

The Worm Gear Drive WE19 shows how mechanical innovation drives progress. It optimizes digital factories through accurate simulation. It enables the mechanical intelligence needed beyond Moore's Law. It ensures reliable operation in harsh industry and powers lunar exploration. The WE19's compact, high-torque, reliable design is indispensable.

Its blend of high reduction, self-locking safety, smooth operation, and robust construction ensures it remains a motion control cornerstone. At LYRADRIVE, we specialize in cutting-edge drives like the WE19. We offer deep engineering expertise and a commitment to quality.

Ready to integrate WE19 power and reliability into your project? Contact LYRADRIVE today for expert consultation and tailored solutions