Worm Gear Drive WE14: A Groundbreaking Solution in High-Precision Transmission

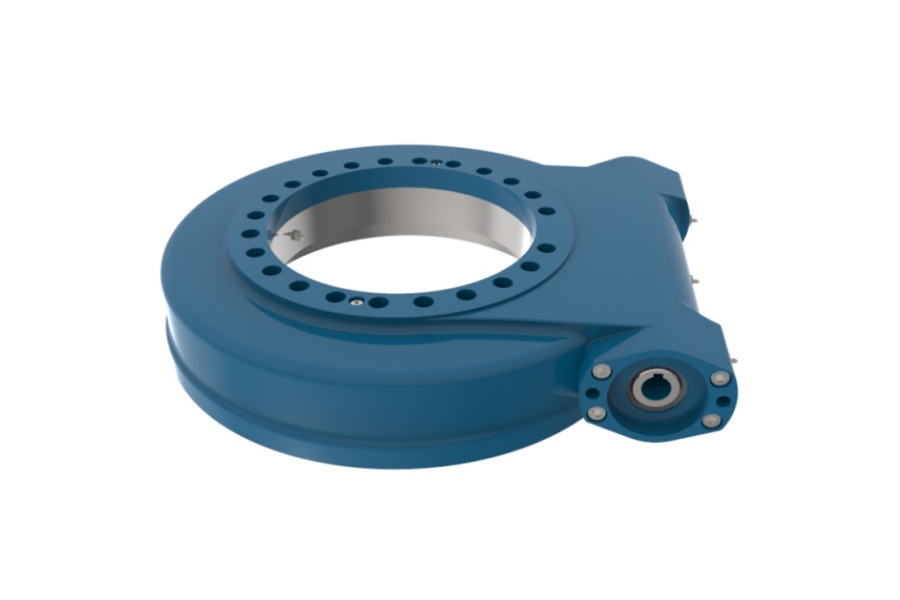

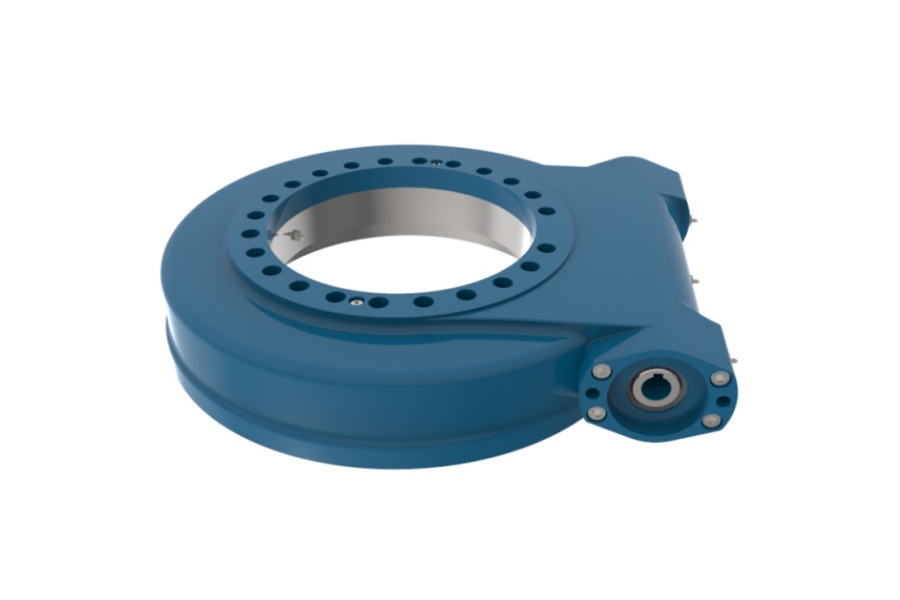

What is Worm Gear Drive WE14?

Worm Gear Drive WE14 adopts an innovative worm gear transmission structure, achieving power transfer through precision meshing. The device is manufactured from high-strength special alloy materials and undergoes specialized heat treatment processes, ensuring stable performance even under extreme conditions. Its unique self-locking feature effectively prevents load reversal, with a safety factor leading the industry. Compared to traditional gear transmissions, WE14 offers a higher reduction ratio (up to 100:1) and smoother transmission performance, while reducing noise levels by over 30%.

Rocket Engine Test Bench Deceleration System

In the aerospace sector, the WE14 series plays a critical role in rocket engine test bench deceleration systems. Its impact-resistant design withstands instantaneous shock loads of up to 2,500 N·m, and precision-machined worm gear pairs control transmission errors within 0.03 mm. A specially designed double-layer cooling structure, combined with a high-performance lubrication system, enables stable operation at 250°C. In practical applications, WE14 has passed rigorous 100-hour continuous operation tests, with all performance metrics exceeding industry standards.

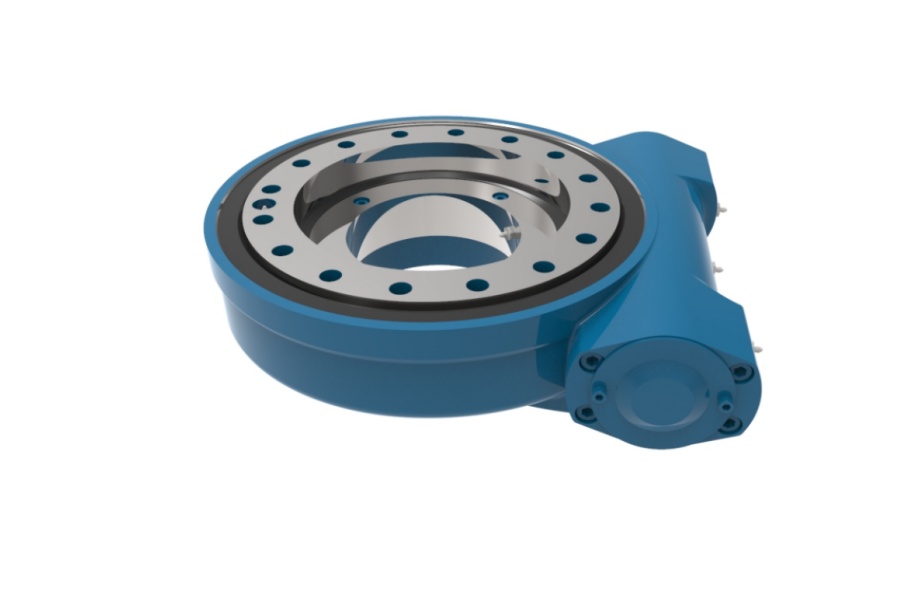

Oversized Worm Gear Reducer

For heavy industrial applications, the WE14 series offers customized oversized solutions. It can produce worm gear components up to 5 meters in diameter, using a patented nickel-aluminum bronze alloy formula and specialized heat treatment to increase load capacity by 45%. The innovative housing structure, optimized via finite element analysis, ensures uniform stress distribution and extends service life to 180,000 hours. Case studies show that in port crane applications, WE14 reducers operated continuously for 3 years without major repairs, setting a new industry benchmark.

WE14 Differentiated Optimization Strategies

Material Innovation: Patented nickel-aluminum bronze worm gears paired with dual-carburized alloy steel worms reduce friction coefficient to 0.02.

Process Breakthrough: Five-axis CNC grinding technology achieves tooth surface smoothness of Ra0.4.

Structural Optimization: Modular design enables rapid replacement of key components within 15 minutes.

Smart Upgrade: Optional IoT monitoring system collects 12 real-time operational parameters (vibration, temperature, etc.).

Lubrication Revolution: Dedicated lubrication channel design ensures critical part lubrication, extending oil change cycles by 50%.

Features of Worm Gear Drive WE14

Transmission accuracy meets DIN Grade 2 standard, far exceeding industry averages.

Maximum output torque upgraded to 35,000 N·m, meeting the most demanding conditions.

Operational noise controlled below 58 dB, setting an industry benchmark.

Protection rating of IP67, adaptable to harsh environments.

Service life exceeds 120,000 hours, reducing total ownership costs.

Efficiency increased to 94%, delivering significant energy savings.

Applications of Worm Gear Drive WE14

Aerospace: Satellite tracking systems with 0.01-degree precision.

Wind Power: Yaw systems for 8MW+ turbines, certified by GL.

Rail Transit: High-speed train bogie testing platforms, operating over 10,000 hours without failure.

Military Equipment: Missile launch systems, passing stringent military tests.

Metallurgy: Continuous casting lines achieving 3 years of fault-free operation.

Factors Affecting WE14 Pricing

Raw Material Costs: Special alloys account for 55% of total costs, with price volatility having a significant impact.

Machining Precision: Each accuracy level increase raises production costs by 18–22%.

Customization: Non-standard design fees typically range from 35–50% of standard product costs.

Order Volume: Orders of 50+ units receive a 10% discount; 100+ units receive 15%.

Added Features: Smart monitoring systems increase costs by 25% but reduce maintenance expenses by 30%.

Delivery Time: Rush orders (within 15 days) incur a 20% surcharge.

After-Sales Service: A 5-year warranty adds 8% to costs but extends equipment life by 30%.

Supplier of Worm Gear Drive WE14

Worm Gear Drive WE14 represents a breakthrough in precision transmission by LYRADRIVE. We invite clients across industries to experience WE14’s exceptional performance firsthand. For detailed technical specifications or custom solutions, contact our engineering team. Let’s drive the transformation from "Made in China" to "Created in China" together!

LYRADRIVE provides comprehensive technical support for WE14 series products, including:

Free operational analysis and selection services

3D simulation verification

On-site installation guidance

Operator training

Lifetime technical consulting