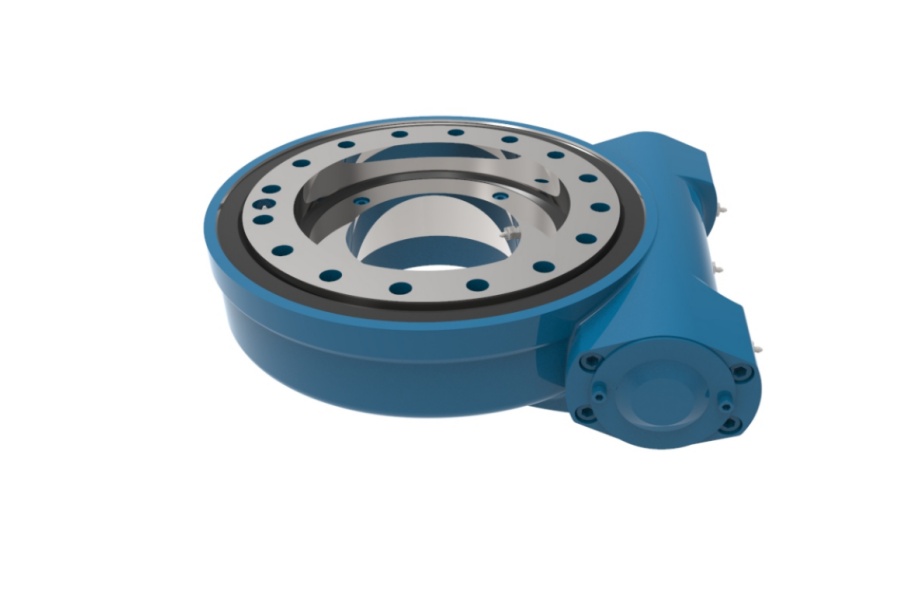

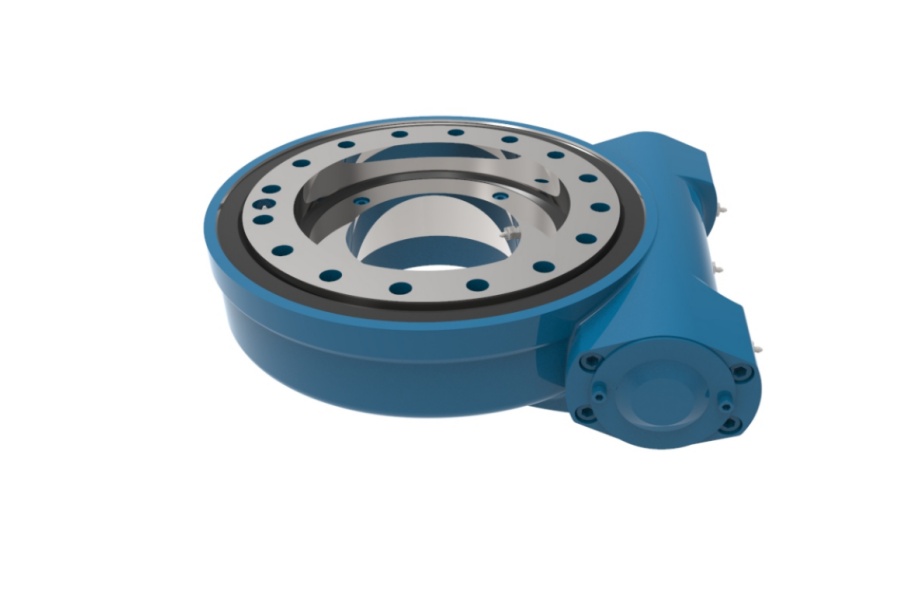

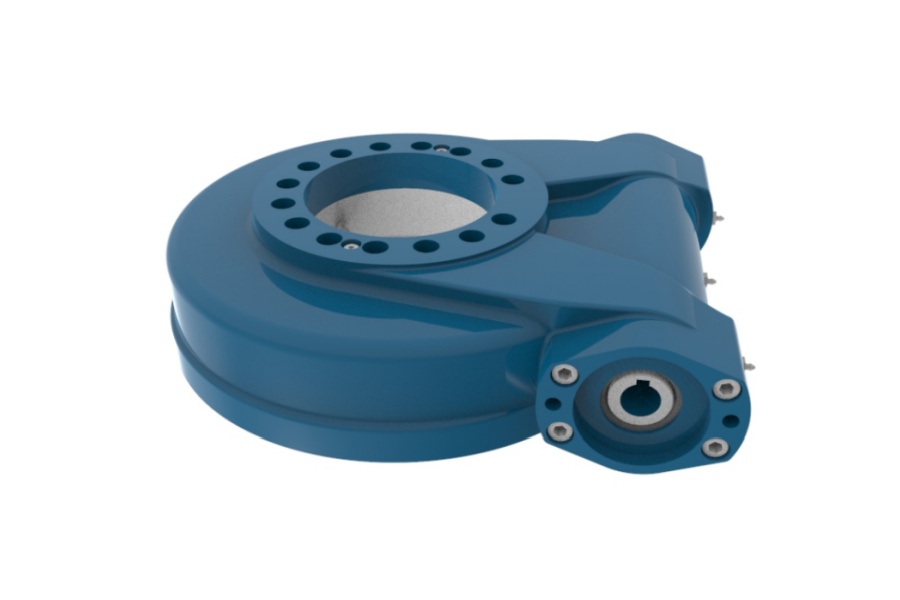

Worm Gear Drive WE9: The Robust Power Guardian for Heavy-Duty Mining Applications

What is Worm Gear Drive WE9?

The Worm Gear Drive WE9 is a high-performance right-angle reducer specifically designed for extreme environments in mining, metallurgy, and heavy industry. Its core features a reinforced worm gear pair structure:

Worm: Made from high-hardness alloy steel, precision ground.

Worm Wheel: Gear ring made from wear-resistant tin bronze (e.g., ZCuSn10P1).

Significantly increased center distance and a reinforced housing endow it with exceptional heavy-load capacity and impact resistance. It delivers stable low-speed, ultra-high torque output (up to tens of thousands of Newton-meters) and possesses excellent self-locking properties (under specific ratios). IP65+ high-grade sealing protection effectively resists dust and moisture ingress. Combined with optimized heat dissipation and long-lasting lubrication design, it ensures ultimate operational reliability and extended service life under continuous high loads and severe conditions. It is the heavy-duty industrial transmission cornerstone guaranteeing safe, efficient, and uninterrupted power transfer for core equipment.

Mining Reducer Selection: Confronting Severe Challenges

The mining operating environment presents the ultimate test for mechanical equipment: heavy-load impacts (ore crushing, hoisting), continuous high loads, pervasive dust, damp corrosion, space constraints, and difficult maintenance. Selecting a reducer in this environment is no easy task. Key considerations must include:

Torque Capacity: Paramount to withstand immense stresses during startup and operation.

Reliability & Durability: Critical lifelines; any failure can lead to significant losses.

Transmission Efficiency: Impacts long-term operating costs.

Compact Structure: Adapts to limited space.

Superior Sealing: Essential to defend against dust and moisture.

Effective Heat Dissipation: Ensures sustained operation.

Ease of Maintenance: Particularly crucial in remote mining areas.

Total Cost of Ownership (TCO): Requires comprehensive evaluation of purchase price, energy consumption, maintenance, and downtime losses.

Core Technical Specifications: The Hardcore Capabilities of WE9 Reducer

The WE9 series, an upgraded and reinforced version of the WE7, is purpose-built for heavy-duty sectors like mining. Its core parameters showcase its robust capabilities:

Center Distance: Significantly larger than WE7, providing a sturdier housing structure and more internal component space, forming the foundation for load-bearing. Typical range: 90mm to 280mm or larger (model-dependent).

Ratio Range: Wide single-stage reduction ratio coverage, typically i=7.5 to i=100, with some models higher, satisfying diverse low speed, high-torque needs.

Input Power Range: Compatible with a broad range of motor powers, from a few kW to tens of kW and beyond (e.g., 0.12kW ~ 55kW or higher, model-dependent).

Input Speed: Standard design typically suits 1500 rpm or 1000 rpm (4-pole/6-pole motors). Special designs accommodate higher speeds.

Mounting Options: Highly flexible configurations including Foot Mounting (B5), Flange Mounting (B14/B5), and Shaft Mounting (keyed with locking device), perfectly adapting to various mining equipment layouts.

Housing Material: High-strength cast iron (e.g., HT250) or quality cast steel, ensuring rigidity and impact toughness.

Worm & Wheel Material/Process: Worm: High-quality alloy steel (e.g., 20CrMnTi), carburized, hardened, and precision ground for high hardness and wear resistance. Wheel gear ring: Wear-resistant tin bronze (e.g., ZCuSn10P1), centrifugally cast, ensuring excellent friction pair performance and long life.

Sealing: Standard multiple high-efficiency seals (e.g., radial shaft seals, labyrinth seals), offering IP65 or higher protection against mining dust and moisture.

Lubrication: Recommends high-performance extreme pressure (EP) industrial gear oil for adequate lubrication and good heat dissipation under heavy loads.

Power Core: Analyzing WE9 Worm Gear Drive Output Torque

The core value of the WE9 reducer lies in its powerful output torque conversion capability. Output torque (T2) can be estimated using this formula (refer to manufacturer's precise selection manual for actual values):

T2 = 9550 * P1 * η * i / n1

Where:

T2: Output Torque (Unit: Newton-meter, Nm)

P1: Input Power (Unit: Kilowatt, kW)

η: Reducer Transmission Efficiency (Worm gear efficiency typically 0.7 - 0.9+, depends on ratio, load, manufacturing quality)

i: Transmission Ratio

n1: Input Speed (Unit: Revolutions per minute, rpm)

The core advantage of WE9 is its design's ability to deliver sustained, stable output torque far exceeding general-purpose models (like WE7). Its rated torque range is extensive, spanning from hundreds to tens of thousands of Newton-meters (e.g., 800 Nm ~ 40,000 Nm or higher, model-dependent). During selection, it is paramount to ensure the selected WE9 model's rated output torque (including the necessary service factor - often SF=1.5 or higher for mining) meets or exceeds the maximum torque required by the actual operating conditions. This is crucial for ensuring long-term, trouble-free equipment operation. LYRADRIVE provides professional selection support to precisely match your torque requirements.

Exceptional Attributes: The Hardcore Advantages of WE9 Worm Gear Drive

The WE9 reducer excels in demanding applications like mining due to its array of hardcore advantages:

Exceptional Heavy-Duty Capacity: Reinforced housing, large center distance, premium materials, and precision manufacturing grant superior load-bearing and impact resistance, undaunted by mining shocks.

Low-Speed, High-Torque Output: Inherent single-stage high reduction ratio perfectly suits the core mining need for powerful low-speed drives.

Superior Structural Compactness: Right-angle output configuration maximizes space savings and simplifies drive layout.

Smooth and Quiet Operation: Worm gear meshing characteristics result in low vibration and noise levels, optimizing the working environment.

Reliable Self-Locking (at Specific Ratios): Provides dependable self-locking under suitable ratios, enhancing equipment safety and preventing unintended reversal.

Robust Environmental Adaptability: Multiple high-efficiency seals and high protection ratings (IP65+) effectively resist mining dust, moisture, and water splash.

Extended Service Life: Wear-resistant worm wheel material, optimized tooth profile design, and adequate lubrication ensure longevity in harsh conditions, reducing lifecycle costs.

Relatively Simple Maintenance: Structural design considers maintenance needs, facilitating routine upkeep.

Key Applications: The Vast Arena for WE9 Worm Gear Drive

Leveraging its robust capabilities, the WE9 reducer is the preferred power transmission solution for critical equipment in mining and heavy industries:

Mining Hoisting & Transport: Mine hoists, belt conveyor drive units (especially heavy-duty, long-distance, steep incline), feeders.

Material Crushing & Processing: Jaw crushers, hammer crushers, roll crushers, vibrating screens.

Mixing & Blending: Large mixers, twin-shaft mixers, concrete batching plants.

Lifting & Handling: Hoisting and travel mechanisms for various cranes (overhead, gantry, jib), electric hoists.

Building Materials & Metallurgy: Rotary kiln drives, auxiliary drives for rolling mills, straightening machines, large valve actuators.

Environmental & Energy: Wastewater treatment mixers, waste processing equipment, flue gas desulfurization mixer drives.

General Industrial Heavy-Duty: Any application requiring low speed, high torque, right-angle transmission, and high reliability, such as large turntables, internal mixers, construction machinery.

Value Composition: Factors Influencing WE9 Worm Gear Drive Price

The price of a WE9 reducer is not a single metric; it is influenced by multiple key factors:

Core Specification Parameters: Center distance (larger = higher cost), required torque/power rating (higher capacity = higher cost), transmission ratio (non-standard ratios may increase cost) form the pricing foundation.

Material & Process Grade: Using high-strength housing materials (e.g., cast steel vs. cast iron), high-performance worm wheel ring material (e.g., high-tin bronze), precision worm heat treatment and grinding processes significantly increase cost but deliver higher reliability and lifespan.

Customization Level: Special mounting configurations (e.g., specific flanges or shaft mount), non-standard input/output shaft dimensions or types, custom protective coatings (e.g., anti-corrosion), special sealing requirements (higher IP rating) add cost.

Technical Configuration Options: Integration of forced lubrication systems, cooling devices (fans, water jackets), torque arms, encoder interfaces, special sensors directly impacts price.

Brand & Quality Assurance: Reputable brands (like LYRADRIVE) invest in material control, manufacturing precision, rigorous testing, and reliable after-sales service, typically commanding higher value and price points.

Order Quantity & Supply Chain: Bulk purchases usually secure better pricing; fluctuations in raw material costs (e.g., copper, steel) affect the final product price.

Market Competition: Pricing strategies vary among different brands.

Supplier of Worm Gear Drive WE9

LYRADRIVE deeply understands the stringent demands mining equipment places on power transmission systems. Our WE9 series worm gear reducers are the crystallization of engineering expertise and reliable quality. From core material selection to precision manufacturing processes and stringent factory testing, every step embodies our relentless pursuit of "reliability and durability." Their exceptional heavy-load capacity, optimized transmission efficiency, robust environmental adaptability, and long service life are key to ensuring the continuous, efficient, safe, and stable operation of your mining equipment.

Facing complex mining conditions and diverse equipment requirements, we go beyond standard products. LYRADRIVE's professional team is ready to provide you with precise selection support, flexible non-standard customization solutions (special shaft extensions, flanges, seals, coatings, etc.), and timely, localized technical services. We are committed to being your trusted power transmission partner, helping you effectively reduce overall equipment operating costs and enhance production efficiency.