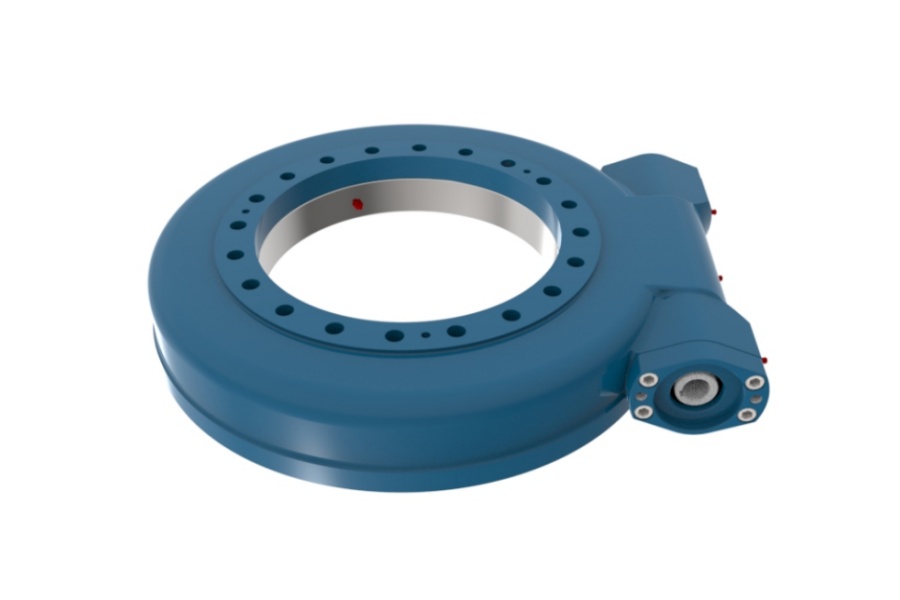

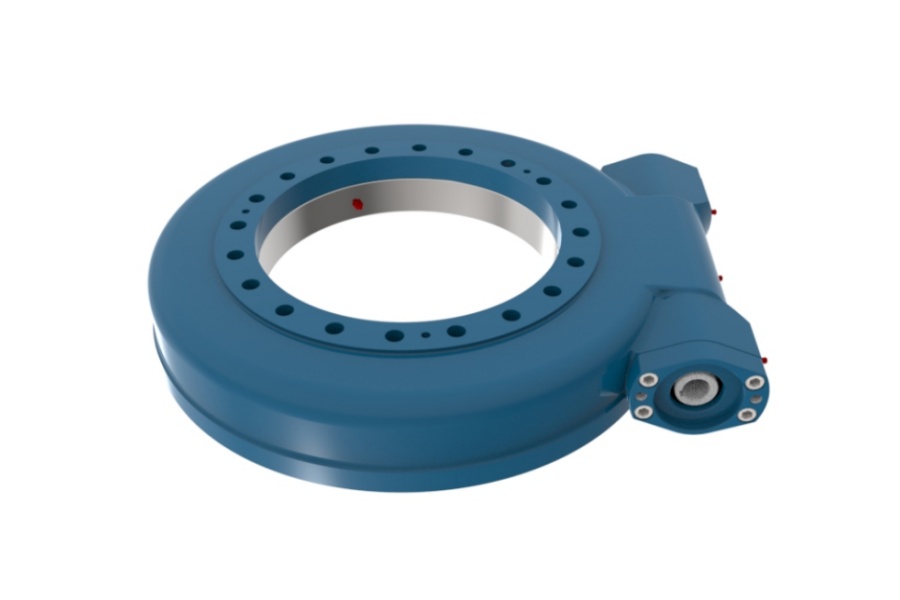

Worm Gear Drive WE17 is a Reliable Power for Heavy Jobs

What is Worm Gear Drive WE17

Worm Gear Drive WE17 is a special gearbox designed for industrial machines needing lots of turning power and safety. It has a strong case, a carefully made screw-like worm shaft, and a matching gear wheel inside. This sealed design keeps dirt and water out. The WE17 can handle pushing, pulling, and twisting forces all at once. A key feature is its self-locking ability, meaning it holds position even when power is off, making things safer. It's built for reliable work in demanding places.

Sliding Speed and Efficiency in Worm Gears

In worm gear drives like the WE17, the worm shaft slides against the gear wheel much more than it rolls. This sliding action creates friction. The speed of this sliding affects how much power is lost as heat – faster sliding usually means lower efficiency. While worm gears aren't the absolute most efficient (often 50-90% efficient depending on setup), the WE17 uses optimized shapes (like ZA or ZK profiles) and special materials to reduce this friction as much as possible. This helps it work efficiently within its strong points: high power, compact size, and self-locking safety.

Key Features of Worm Gear Drive WE17

The WE17 stands out because of these important features:

High Turning Power: It delivers a strong 12.96 kN.m of turning force for heavy loads.

Handles Twisting Forces: It resists twisting forces up to 142.4 kN.m, keeping things stable.

Strong Holding Power: It holds its position firmly with 72.3 kN.m of holding torque, acting like a built-in brake.

Big Speed Reduction: Its 104:1 ratio slows down input speed a lot while boosting turning power significantly.

Precise Movement: It moves very accurately, within 0.1 degrees, for jobs needing exact positioning.

Self-Locking Safety: It naturally locks in place when power stops, preventing unwanted movement.

Weather Resistant: Its IP65 rating means it's well protected against dust and water spray.

Works with Different Motors: You can easily connect it to hydraulic motors or electric motors (including servo motors).

Where is Worm Gear Drive WE17 Used

The WE17's strength and safety features make it useful in many areas:

Man Lifts and Aerial Platforms: For safe and stable rotation and lifting of platforms high in the air.

Mining Equipment: Handles tough jobs like positioning drills and moving heavy materials underground.

Dumpers and Mixers: Powers the turning of hoppers, mixers, and tumblers in factories.

Construction Machinery: Used in cranes, concrete pumps, and excavators for reliable rotation on job sites.

Factory Robots: Provides precise turning for heavy tools or parts in automated production lines.

Solar Panel Trackers: Accurately turns solar panels to follow the sun, locking securely against wind.

Warehouse Systems: Powers turntables and sorting machines that handle heavy pallets or goods.

What Affects the Price of Worm Gear Drive WE17

The cost of a WE17 drive isn't fixed. It depends on several things:

Custom Changes: If you need special mounting points, shaft sizes, seals, or finishes, it costs more.

Materials Used: Standard materials are common, but special wear-resistant or corrosion-resistant alloys cost extra.

Order Size: Buying more units usually lowers the price per unit.

Extra Precision: Tighter manufacturing tolerances beyond the standard high precision increase cost.

Special Tests: If specific certifications or tests (like extra durability or salt spray) are needed, it adds cost.

Added Parts: Including sensors, extra brakes, or motors increases the total price.

Shipping and Location: Where it's made and shipped to affects the final cost.

For the best price based on your specific needs and quantity, it's best to ask the manufacturer directly.

Supplier of Worm Gear Drive WE17

LYRADRIVE is the expert company that designs and builds the Worm Gear Drive WE17. They focus on high quality using precise manufacturing and top-grade materials. Their team works with customers to create solutions that fit exact needs. LYRADRIVE keeps improving the WE17 through research and development to meet industry demands, making it a trusted choice worldwide for reliable power transmission.