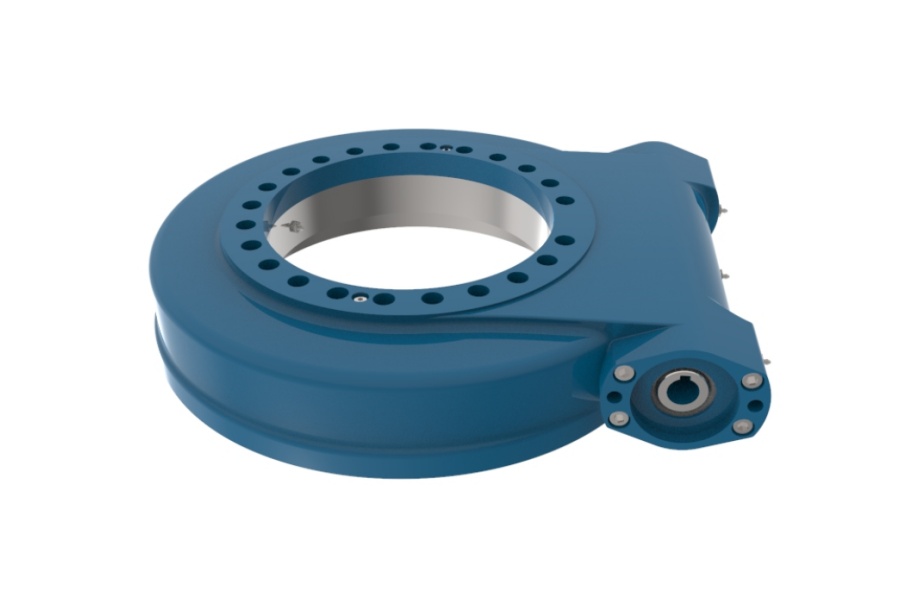

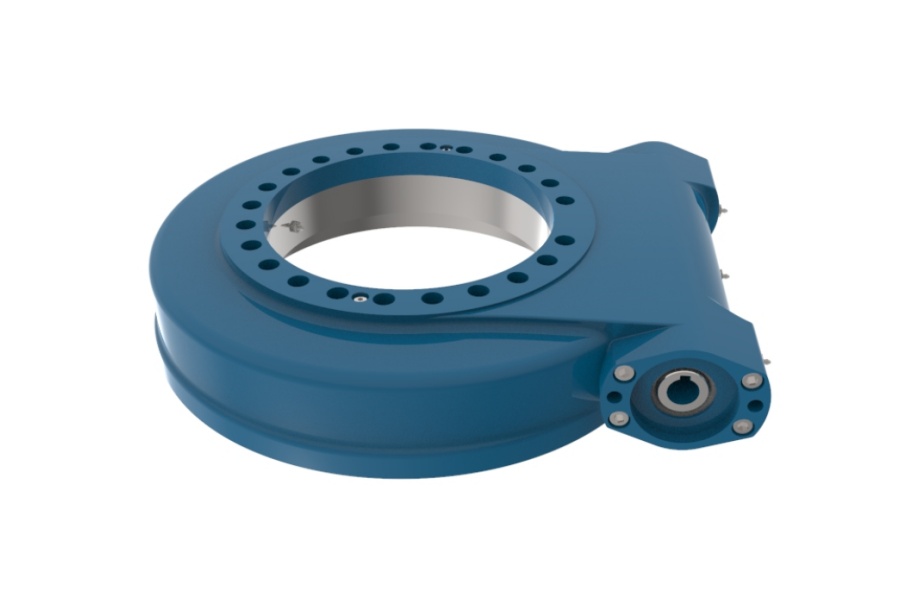

Worm Gear Drive WE14 in Demanding Rotary Applications

What is Worm Gear Drive WE14

Worm Gear Drive WE14 represents a high-capacity evolution in integrated slewing drive technology, meticulously designed for the most demanding industrial environments where reliability, power, and safety are non-negotiable. Its core construction integrates a robust, precision-machined housing (base), a hardened steel worm shaft, and a meticulously matched worm wheel, typically crafted from high-strength bronze or specialized composite materials. Engineered to operate flawlessly under sealed conditions, the WE14 excels at simultaneously managing substantial axial loads, significant radial forces, and extreme tilting moments far exceeding many comparable units. The defining characteristic, inherent in its worm gear design, is its powerful self-locking capability. This critical safety feature prevents back-driving, ensuring that any load connected to the output cannot cause unintended rotation when drive power is removed – a fundamental requirement for safety in lifting, positioning, and elevated work platforms. The WE14 often utilizes optimized ZA or ZK tooth profiles between the worm and wheel, ensuring minimal backlash, efficient power transmission with reduced sliding friction, and enhanced durability under continuous heavy loads. This integrated package simplifies installation and provides a ready-engineered solution for complex rotational motion challenges.

How Should Bolts Be Correctly Selected for Installing a Slewing Drive?

The proper selection and installation of bolts are absolutely critical for the safe, reliable, and long-lasting performance of a slewing drive like the WE14. These bolts are responsible for transmitting immense operational forces (axial, radial, tilting moments) and holding torque from the drive unit into the supporting structure. Incorrect bolt selection or installation is a primary cause of premature failure, joint loosening, structural damage, and catastrophic safety hazards. Follow these essential guidelines:

Adhere Strictly to Manufacturer Specifications: The drive manufacturer (LYRADRIVE) provides detailed specifications for the required bolts. This includes the bolt grade (e.g., ISO 10.9, SAE Grade 8, ASTM A490), bolt diameter (M size), bolt length, thread type and pitch, and required quantity. Never substitute with lower-grade or undersized bolts. Using bolts weaker than specified compromises the entire assembly's integrity.

Understand the Load Requirements: Bolts for slewing drives like the WE14 primarily experience tensile preload (clamping force) and shear forces. The clamping force generated by proper tightening is what creates friction to resist shear loads and separation. The high holding torque (48 kN·m) and tilting moment capacity (71.2 kN·m) of the WE14 generate significant forces that the bolts must withstand without yielding or fatiguing.

Prioritize High-Strength Bolts: Bolts meeting ISO 10.9, SAE Grade 8, or ASTM A490 specifications are typically mandatory for drives like the WE14 due to their high yield and tensile strength. These bolts are made from medium carbon alloy steel, quenched, and tempered.

Ensure Correct Length: Bolts must be long enough to fully engage the thread in the receiving structure (nut or tapped hole) with sufficient shank length. A general rule is that the engaged thread length should be at least 1 to 1.5 times the bolt diameter. The bolt should protrude slightly beyond the nut. Bolts that are too short risk thread stripping; bolts that are too long can bottom out or cause interference.

Use Appropriate Washers: High-quality, hardened steel washers are essential:

Flat Washers: Used under the bolt head and/or nut to distribute the clamping force over a wider area, preventing damage to the mounting surfaces and helping maintain clamp load, especially on softer materials. They also provide a consistent bearing surface.

Spring Washers (Use with Caution): While sometimes specified, modern best practices often favor controlled torque tightening over spring washers for high-load applications. If specified, use only high-quality spring washers designed for the bolt size and load.

Preferred Alternative - Nord-Lock Washers: For critical, high-vibration applications, serrated locking washers (like Nord-Lock) are highly recommended. They provide superior vibration resistance by creating a wedge-locking effect through their interlocking serrations.

Employ the Correct Tightening Method & Torque:

Torque Wrench is Mandatory: Always use a calibrated torque wrench.

Follow Specified Torque Value: Use the exact torque value specified by LYRADRIVE for the specific bolt grade, size, and lubrication condition (dry vs. lubricated threads – manufacturer instructions are paramount). Under-torquing fails to generate sufficient clamp load, leading to joint loosening. Over-torquing can stretch (yield) the bolt, drastically reducing its strength and causing failure.

Use the Correct Tightening Sequence: Follow a star or cross pattern tightening sequence, especially on flange mounts. Tighten bolts incrementally (e.g., 30%, 60%, 100% of final torque) in multiple passes to ensure even clamp load distribution and prevent distortion of the drive housing or mounting structure. Uneven tightening can warp components and lead to premature bearing or gear failure.

Consider Torque + Angle Method (If Specified): For critical applications, the manufacturer might specify a torque-plus-angle method for greater accuracy in achieving the desired bolt preload.

Prepare Threads and Surfaces: Ensure both the bolt threads and the threads in the receiving structure (nut or tapped hole) are clean, dry (unless specified otherwise by the bolt manufacturer/torque specs), undamaged, and free of oil, grease, dirt, or debris. Damaged threads significantly weaken the connection. Surfaces under the bolt head and nut should be clean, flat, and perpendicular to the bolt axis.

Apply Thread Locker (If Specified): If recommended by LYRADRIVE to prevent loosening due to vibration, apply the correct type and amount of thread locking compound (e.g., Loctite 243 for medium strength, removable applications) to the cleaned bolt threads. Follow the compound manufacturer's instructions.

Re-torque After Initial Run-In: For extremely critical applications or after the first period of operation (e.g., 50-100 hours), re-check the bolt torque according to the manufacturer's recommendations. Initial settling can sometimes cause a slight loss of preload.

Use Matching High-Strength Nuts: If using nuts, they must match the bolt grade (e.g., ISO 10 nut for ISO 10.9 bolt). Never mix grades. Flange nuts or stiff nuts are often preferred.

Neglecting proper bolt selection and installation procedures jeopardizes safety and the performance of your valuable Worm Gear Drive WE14 investment. Always prioritize the manufacturer's specific, detailed instructions.

Worm Gear Drive WE14 Key Features

The WE14 distinguishes itself through a suite of robust engineering features designed for ultimate performance and reliability in high-stress environments:

Exceptional Output Torque: Delivering a formidable rated output torque of 10.8 kN·m, the WE14 provides the brute force necessary to drive heavy loads in demanding applications like large lifting platforms, heavy-duty industrial mixers, and robust material handling systems, where high rotational force is essential.

Superior Tilting Moment Capacity: Engineered for unwavering stability under extreme off-center or uneven loading, the WE14 withstands immense tilting moments up to 71.2 kN·m. This capability is crucial for applications like large boom lifts operating on uneven terrain, heavy-duty rotating platforms, or machinery subject to significant dynamic side loads, ensuring structural integrity and operational safety.

Robust Holding Torque: Featuring a powerful holding torque of 48 kN·m, the WE14 reliably locks its position when input power ceases. This inherent braking force, intrinsic to its efficient worm gear design, is vital for safety in vertical lifting applications, precise positioning tasks (like solar trackers against wind loads), or any scenario where unintended movement under load presents a severe hazard.

High Reduction Ratio: With a substantial 86:1 reduction ratio, the WE14 efficiently converts relatively high input speed into very low output speed while multiplying torque significantly. This high ratio is fundamental for applications requiring powerful, slow, and precisely controlled rotational movement from a compact drive unit.

Precision Tracking & Repeatability: The WE14 boasts outstanding tracking accuracy (repeatability) of ≤ 0.1°. This exceptional level of precision ensures consistent, reliable positioning cycle after cycle, which is critical for automated manufacturing processes, robotic arm joints, precision scanning equipment, alignment tasks, and any application demanding exact angular repeatability and minimal drift.

IP65 Protection Rating: The housing features meticulous sealing, achieving an IP65 rating. This signifies complete protection against dust ingress and protection against low-pressure water jets from any direction. This robust sealing makes the WE14 exceptionally durable and suitable for continuous operation in harsh, dirty, wet, or outdoor environments, significantly enhancing its operational lifespan and reducing maintenance needs.

Inherent Self-Locking: The fundamental geometry of the worm and wheel provides a highly reliable natural self-locking characteristic. Force applied to the output wheel cannot back-drive the input worm shaft. This is a critical passive safety feature, preventing load drops in lifting applications or unintended movement when the drive is not powered, adding an essential layer of operational security without requiring additional brakes in many scenarios.

High Efficiency Design: Optimized tooth profiles (like ZA/ZK) and precision manufacturing minimize sliding friction inherent in worm gears, leading to improved efficiency, reduced operating temperatures, and lower energy consumption compared to less advanced worm drive designs, contributing to operational cost savings.

Drive Motor Versatility: The WE14 is designed for seamless integration with either hydraulic motors or electric motors (geared or direct drive), offering significant flexibility to match the preferred or existing power source within the application, simplifying system design and integration.

Compact Integrated Design: Combining the high-strength worm set, large capacity bearings, and robust seals into a single, pre-assembled, and pre-lubricated unit, the WE14 offers a space-saving solution. This simplifies installation logistics, minimizes complex alignment procedures on-site, and provides a rugged, ready-to-install package engineered to handle combined loads efficiently.

Durable Construction & Materials: Manufactured using premium, high-grade materials (hardened alloy steel worms, high-strength bronze or advanced composite worm wheels) and precision machining processes, the WE14 is built for maximum longevity and reliable performance under continuous, heavy-duty operation, offering excellent resistance to wear, pitting, and fatigue.

Worm Gear Drive WE14 Applications

Leveraging its unparalleled combination of high torque, precision, self-locking security, and ruggedness, the Worm Gear Drive WE14 is the driving force behind critical motion in diverse and demanding industries:

Large Aerial Work Platforms (AWPs): A primary application is in the slewing (rotational) drive mechanism of large boom lifts, spider lifts, and heavy-duty scissors lifts. The WE14 provides the massive torque needed to smoothly and safely rotate extended boom structures, while its high holding torque and self-locking ensure the platform remains rock-steady when elevated, even during power loss, protecting workers at significant heights.

Mining, Quarrying & Heavy Material Handling: The drive's exceptional robustness, high torque (10.8 kN·m), and tilting moment capacity (71.2 kN·m) make it indispensable in extreme mining and bulk handling environments. It powers the slewing mechanisms of large drill rigs, heavy-duty stackers and reclaimers, ship loaders/unloaders, conveyor belt tensioning/tracking systems, and large bulk material handling grapples.

Industrial Tipping and Rotation Mechanisms: The WE14 excels in applications requiring controlled tilting or rotation of very heavy components. This includes rotating large industrial mixers/reactors, indexing heavy turntables for manufacturing, tipping mechanisms for massive foundry ladles or slag pots, and precise positioning in heavy assembly lines or steel coil handling equipment.

Construction & Earthmoving Machinery: Beyond large AWPs, the WE14 is integrated into heavy construction equipment requiring reliable high-torque rotational motion. This includes slew drives for large excavators and cranes (especially auxiliary attachments), rotation mechanisms for piling rigs and drilling attachments, and positioning systems for heavy concrete pump booms.

Heavy-Duty Material Handling Systems: Used in port cranes (container handling spreaders), automated storage/retrieval systems (AS/RS) for heavy pallets, heavy palletizers/depalletizers for large items (e.g., building materials, machinery), and rotating transfer stations in heavy manufacturing.

Renewable Energy - Large Scale Solar Tracking: Employed in utility-scale solar tracker systems to precisely orient massive arrays of photovoltaic panels towards the sun. Its high holding torque (48 kN·m) is crucial for maintaining position against strong wind loads, while precision (≤0.1°) maximizes energy capture efficiency.

Industrial Automation & Heavy Robotics: The precision (≤0.1°) and immense holding torque of the WE14 make it suitable for heavy-duty robotic arms, large automated guided vehicle (AGV) turntables carrying significant loads, and other robotic applications requiring accurate, stable positioning without continuous motor power consumption to hold position.

Stage, Entertainment & Special Effects: Powers the smooth, controlled, and reliable rotation of extremely heavy stage platforms, large lighting trusses, giant video walls, and complex special effects machinery, where absolute safety and precision are paramount during performances.

Marine & Offshore Equipment: Used in deck machinery, crane attachments, hatch covers, and positioning systems on vessels and offshore platforms, benefiting from its corrosion resistance (with optional coatings), self-locking, and ability to handle harsh marine environments.

Factors Influencing Worm Gear Drive WE14 Pricing

The cost of a Worm Gear Drive WE14 varies based on several key factors, reflecting its engineering complexity and customization potential. Understanding these aids in budgeting and procurement:

Core Specifications & Standard Configuration: The base price is driven by the standard WE14 specifications: output torque (10.8 kN·m), tilting moment (71.2 kN·m), holding torque (48 kN·m), ratio (86:1), and IP65 rating. Units built precisely to these standard specs form the pricing baseline.

Customization & Configuration Variations: Deviations from the standard WE14 design significantly impact cost. Key variations include:

Alternative Reduction Ratios: While 86:1 is standard, requiring a different ratio necessitates redesigning the gear set, altering manufacturing processes and costs.

Mounting Interface Customization: Standard flanges are included. Custom mounting patterns, special adapter plates, or unique base geometries require additional engineering and machining.

Shaft & Flange Modifications: Variations in input shaft type (e.g., splined, keyed, special diameters/lengths), output flange design (e.g., custom bolt patterns, through-holes, tapped holes), or special sealing requirements add complexity.

Enhanced Sealing (IP Rating): While IP65 is standard, requests for higher ingress protection (e.g., IP66, IP67, IP69K) demand specialized seals, gaskets, and housing designs, increasing cost.

Material Selection Impact: Material choices profoundly affect price:

Worm Wheel Material: Standard high-strength bronze is common. Upgrading to specialized, high-wear-resistance bronze alloys, advanced polymers, or composite materials for extreme loads, corrosion resistance, or specific friction properties significantly increases material costs.

Worm Shaft Material: Standard hardened alloy steel. Specific high-alloy steels for extreme environments or wear resistance add cost.

Surface Treatments & Coatings: Standard protective finishes are included. Applying specialized corrosion-resistant coatings (e.g., high-performance paints, electroless nickel plating, Dacromet) for harsh environments (marine, chemical) adds cost.

Additional Features & Options: Integrating non-standard features increases price:

Integrated Sensors: Adding encoders, resolvers, temperature sensors, or vibration sensors requires components, machining modifications, and wiring.

Special Lubricants: Pre-filling with specific high-performance synthetic grease, food-grade grease, or grease for extreme temperatures instead of standard industrial lubricant.

Non-Standard Bearings: Requests for bearings with higher precision ratings, different clearance classes, or specific sealing for the internal bearings.

Special Testing: Performing specific, non-standard acceptance tests (e.g., extended full-load endurance testing, salt spray testing, specific noise level testing) adds time and resources.

Order Volume & Economies of Scale: Significant per-unit discounts are typically applied for larger volume purchases (bulk orders). The fixed costs of setup, engineering (for custom orders), and tooling are distributed across more units, reducing the individual cost. Single unit or small batch orders carry a higher relative cost burden.

Raw Material Costs & Market Dynamics: Fluctuations in global prices for key raw materials (steel, copper, tin, aluminum, specialty alloys) directly impact manufacturing costs. Energy prices, logistics costs, and broader supply chain conditions also influence the final price over time.

Supplier Value-Add & Support: While the unit cost is primary, suppliers offering extensive technical support during selection/design, shorter lead times, comprehensive warranties, readily available spare parts, and responsive after-sales service may command a slight premium reflecting the added value and reduced risk for the buyer.

Geographic Factors: Pricing can vary regionally based on local manufacturing costs, import duties, taxes, and distributor margins.

For accurate and competitive pricing tailored to your specific application needs and any desired customizations, direct consultation with the manufacturer or authorized distributor is essential.

Supplier of Worm Gear Drive WE14

LYRADRIVE specializes in engineering and manufacturing high-performance Worm Gear Drive WE14 units. Our commitment to precision engineering and stringent quality control ensures every drive meets rigorous international standards. Utilizing advanced manufacturing techniques and premium materials, we deliver WE14 solutions renowned for reliability in demanding applications. LYRADRIVE provides tailored technical support and customization options to optimize drive integration for specific operational requirements. As an industry leader in slewing drive technology, we empower global industries with robust, high-torque motion solutions