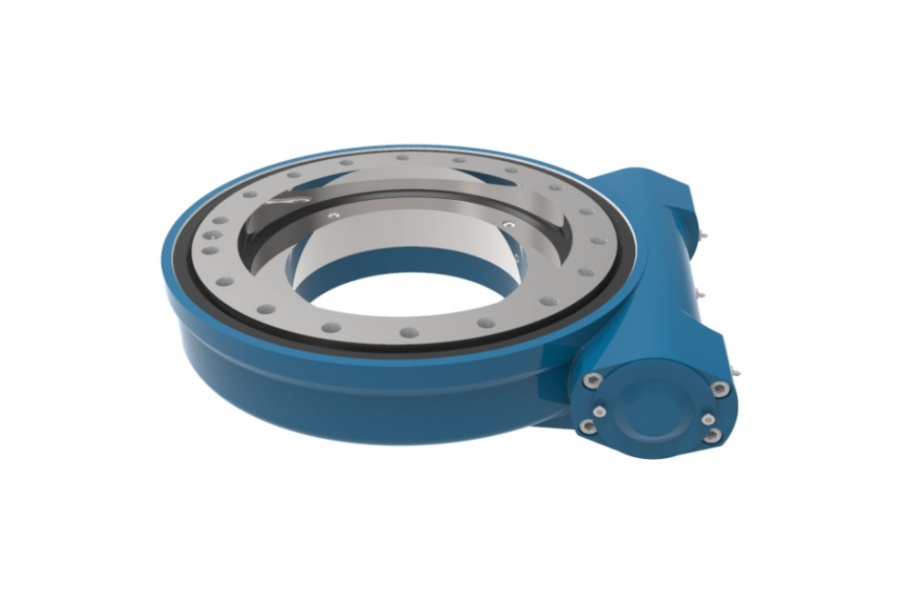

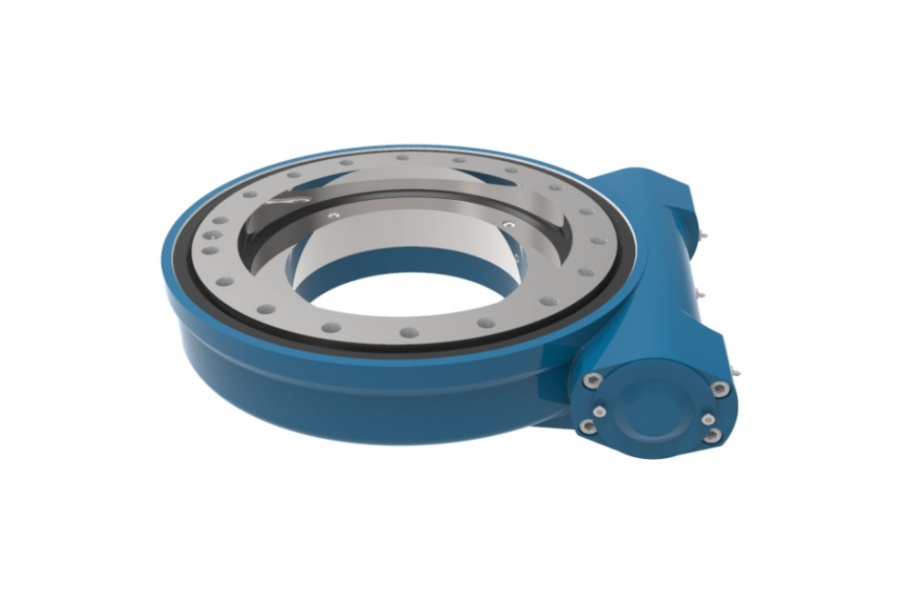

Worm Gear Drive WE12 Robust Precision

What is Worm Gear Drive WE12?

Worm Gear Drive WE12 represents an advanced integrated drive solution meticulously engineered for reliable performance across a broad spectrum of industrial applications. Its core construction comprises a robust housing (base), a precision-ground worm shaft, and a corresponding worm wheel. Engineered to operate effectively under sealed conditions, the WE12 is uniquely capable of simultaneously handling substantial axial loads, significant radial forces, and considerable tilting moments. A defining characteristic of this drive is its inherent self-locking mechanism. This crucial feature prevents the rotation of the driven worm wheel from reversing the direction of the driving worm shaft when input power ceases. This inherent safety significantly enhances operational security and reliability, making the WE12 exceptionally well-suited for applications where stringent safety standards are paramount, such as lifting equipment or positioning systems where unintended movement is unacceptable. The worm and wheel within the WE12 typically employ precise ZA or ZK tooth profiles. This optimized geometry ensures tight meshing, minimizes backlash, enhances power transmission efficiency, and contributes to smoother operation and extended service life by distributing loads more evenly across the tooth surfaces.

How Should Lubrication Be Correctly Applied to a Worm Gear Drive?

Proper lubrication is absolutely critical for ensuring the longevity, efficiency, and reliable operation of any worm gear drive, including the WE12. Incorrect lubrication practices are a primary cause of premature wear, overheating, increased noise, and ultimately, drive failure. Here’s a guide to correct lubrication procedures:

Select the Right Lubricant: Always use the lubricant type (oil or grease) and viscosity grade explicitly recommended by the manufacturer (LYRADRIVE) for the WE12 model under your specific operating conditions (temperature range, load, speed). Worm gears generate significant sliding friction, requiring lubricants specifically formulated with high-pressure (EP) additives and often extreme pressure (EP) additives to withstand the unique stresses at the worm/wheel interface. Using the wrong lubricant can lead to inadequate film strength and rapid wear.

Determine the Correct Quantity: Both under-lubrication and over-lubrication are detrimental. Under-lubrication leads to metal-to-metal contact and wear. Over-lubrication, especially in grease-lubricated units, causes churning, excessive heat generation (due to viscous friction), and potential seal damage. Consult the manufacturer's documentation for the precise fill volume or grease cavity capacity for the WE12.

Follow the Lubrication Interval: Adhere strictly to the recommended lubrication schedule provided by LYRADRIVE. This interval is determined based on operating hours, load intensity, environmental conditions (dust, moisture, temperature extremes), and the specific lubricant used. More severe operating conditions typically necessitate more frequent lubrication. Do not rely solely on a calendar schedule; consider actual operating time.

Use Proper Lubrication Methods:

Grease Lubrication (Common for WE12): Use a grease gun fitted with the correct nipple. Pump grease slowly and steadily until clean grease emerges from the relief plug or seal (if equipped), indicating the cavity is full and old grease/contaminants are purged. Immediately stop pumping once this occurs to prevent overfilling. Wipe away any excess grease expelled from the relief point. Ensure grease fittings and relief points are clean before connecting the grease gun to prevent contaminant ingress.

Oil Lubrication: Fill to the level indicated by the oil sight glass, dipstick, or filler plug position. Ensure the drive is level when checking or filling. For splash lubrication, the correct oil level ensures the lowest rotating element dips into the oil bath. For forced circulation systems, maintain the correct oil level in the reservoir. Always use clean, filtered oil and ensure funnels and fill points are spotless.

Ensure a Clean Environment: Lubrication points (grease nipples, filler plugs, dipsticks, sight glasses) must be meticulously cleaned before removing any plugs or attaching a grease gun. This prevents dirt, grit, or moisture from being introduced into the critical lubrication zone, which acts as an abrasive and accelerates wear.

Monitor Lubricant Condition: Periodically check the lubricant's condition. Look for signs of contamination (gritty feel, discoloration, water emulsion), oxidation (darkening, rancid smell in grease), or excessive metal particles (indicating wear). If contamination or degradation is detected, the lubricant should be changed promptly, and the cause investigated.

Initial Lubrication: New drives are typically factory-lubricated. However, always verify the lubrication status upon receipt and before commissioning. Re-lubricate if necessary following the manufacturer's initial start-up procedure.

Record Keeping: Maintain a log of all lubrication activities, including dates, lubricant type and quantity used, operating hours, and any observations about the lubricant condition or drive performance. This aids in predictive maintenance and troubleshooting.

Neglecting any of these steps compromises the drive's performance and lifespan. Always prioritize the manufacturer's specific instructions for the Worm Gear Drive WE12.

Worm Gear Drive WE12 Key Features

The Worm Gear Drive WE12 distinguishes itself through a combination of robust engineering and precision features, making it a preferred solution for demanding applications:

Exceptional Output Torque: Delivering a rated output torque of 9.5 kN·m, the WE12 possesses the sheer strength to handle substantial operational loads, making it ideal for heavy-duty industrial machinery and lifting applications where high force transmission is non-negotiable.

Superior Tilting Moment Capacity: Engineered for stability under challenging conditions, the WE12 can withstand significant tilting moments up to 57 kN·m. This capability is crucial for applications where loads are applied off-center or where the drive unit itself might experience uneven forces, such as in boom lifts or rotating platforms on uneven terrain, ensuring structural integrity and safe operation.

Robust Holding Torque: Featuring an impressive holding torque of 43 kN·m, the WE12 reliably locks its position when input power is removed. This inherent braking force, stemming from its worm gear design, is vital for safety in lifting applications, precise positioning tasks, or any scenario where unintended movement under load would be hazardous or detrimental.

High Reduction Ratio: With a substantial reduction ratio of 79:1, the WE12 efficiently converts relatively high input speed into significantly lower output speed while dramatically multiplying the output torque. This high ratio is fundamental for applications requiring powerful, slow, and controlled rotational movement from a compact drive unit.

Precision Tracking: The WE12 boasts outstanding tracking accuracy (repeatability) of ≤ 0.15°. This high degree of precision ensures consistent and reliable positioning, which is essential for automated processes, alignment tasks, scanning equipment, and any application demanding exact angular repeatability.

IP65 Protection Rating: The housing is meticulously sealed to achieve an IP65 rating, signifying complete protection against dust ingress and protection against low-pressure water jets from any direction. This robust sealing makes the WE12 exceptionally durable and suitable for operation in harsh, dirty, or wet environments, both indoors and outdoors, significantly enhancing its reliability and lifespan.

Inherent Self-Locking: The fundamental design of the worm and wheel geometry provides a natural self-locking characteristic. This means the drive cannot be back-driven through the output shaft (i.e., force applied to the wheel cannot turn the worm shaft). This is a critical safety feature, preventing load drop in vertical applications or unintended movement when the drive is not powered, adding a vital layer of operational security.

Compact Integrated Design: Combining the worm set, bearings, and seals into a single, pre-assembled unit, the WE12 offers a space-saving solution. This simplifies installation, reduces the need for complex alignment procedures, and provides a robust, ready-to-install package. Its design inherently handles combined loads (axial, radial, tilting) efficiently within this compact envelope.

Durable Construction: Manufactured using high-grade materials (such as hardened steel worms often paired with bronze or specialized polymer wheels) and precision machining, the WE12 is built for longevity and reliable performance even under continuous, heavy-duty operation, offering excellent resistance to wear.

Worm Gear Drive WE12 Applications

Leveraging its unique blend of high torque, self-locking, precision, and ruggedness, the Worm Gear Drive WE12 finds critical roles across diverse industries:

Aerial Work Platforms (AWPs): A primary application is in the slewing (rotational) drive mechanism of boom lifts and spider lifts. The WE12 provides the necessary torque to rotate the boom structure smoothly and safely while its self-locking feature ensures the platform remains securely positioned when elevated, even when powered down, protecting operators working at height.

Mining and Quarrying Equipment: The drive's robustness and high torque capacity make it indispensable in demanding mining environments. It is commonly used in the slewing mechanisms of drill rigs, within conveyor belt tensioning or tracking systems, and in material handling equipment like stackers and reclaimers, where reliability under heavy loads in harsh, dusty conditions is paramount.

Industrial Tipping and Rotation Mechanisms: The WE12 excels in applications requiring controlled tilting or rotation of heavy components. This includes rotating heavy-duty industrial mixers, indexing tables for manufacturing processes, tipping mechanisms for foundry ladles or scrap handling grapples, and precise positioning in assembly lines or material transfer stations.

Construction Machinery: Beyond AWPs, the WE12 is integrated into various construction equipment requiring reliable rotational motion. This includes the slew drives for compact track loaders (CTLs) and mini excavators, rotation mechanisms for drilling attachments, and positioning systems for concrete pumps or crane attachments, enhancing functionality and safety on the job site.

Material Handling Systems: Used in automated storage and retrieval systems (AS/RS) for rotating storage units or positioning cranes, in palletizers/depalletizers for product orientation, and within conveyor diverter arms or rotating transfer stations to direct material flow efficiently.

Packaging Machinery: Provides precise rotational indexing for filling, capping, labeling, and case packing stations, ensuring accurate product handling and high-speed operation.

Renewable Energy: Employed in solar tracking systems to precisely orient photovoltaic panels towards the sun throughout the day, maximizing energy capture efficiency. Its holding torque is crucial for maintaining position against wind loads.

Automation and Robotics: The precision (≤0.15°) and self-locking capability of the WE12 make it suitable for robotic joints, automated guided vehicle (AGV) turntables, and other robotic applications requiring accurate, stable positioning without the need for continuous motor power to hold position.

Stage and Entertainment Technology: Powers the smooth, controlled, and reliable rotation of heavy stage platforms, lighting trusses, and special effects equipment, where safety and precision are critical during performances.

Factors Influencing Worm Gear Drive WE12 Pricing

The cost of a Worm Gear Drive WE12 is not a fixed figure and can vary based on several key factors. Understanding these helps in budgeting and procurement:

Specification and Configuration: The base price depends on the standard WE12 specifications (torque ratings, ratio 79:1, IP65). However, deviations or specific configurations requested by the customer will impact cost. This includes:

Alternative Ratios: While 79:1 is standard, if a different ratio is required (though less common for this specific model designation), it alters the design and manufacturing process.

Mounting Options: Standard mounting flanges or bases are common. Customized mounting interfaces, specific bolt patterns, or special adapter plates add complexity and cost.

Shaft Configurations: Variations in input shaft type (e.g., keyed, splined, different diameters/lengths), output flange design, or the need for through-holes or special output connections increase manufacturing steps.

Sealing Upgrades: While IP65 is standard, requests for higher IP ratings (e.g., IP66, IP67) require enhanced sealing solutions, adding cost.

Material Selection: While the worm is typically hardened steel, the worm wheel material choice significantly affects price. Standard bronze alloys are common. Requests for specialized, higher-performance bronze alloys, advanced polymers, or composite materials for the wheel to handle extreme loads, corrosion resistance, or specific friction properties will increase the unit cost.

Customization Level: Any modification beyond the standard WE12 design constitutes customization. This includes:

Special Coatings: Requests for corrosion-resistant coatings (e.g., specialized paints, plating) for use in highly corrosive environments.

Special Lubricants: Pre-filling with a specific high-performance or food-grade grease instead of the standard industrial lubricant.

Sensors and Feedback Devices: Integration of encoders, resolvers, or proximity sensors for position/speed feedback requires additional components, machining, and wiring.

Non-Standard Dimensions: Altering the overall envelope size or specific internal clearances.

Testing Requirements: Performing specific, non-standard acceptance tests (e.g., extended load testing, specific environmental testing) adds time and resources.

Order Quantity: Like most manufactured goods, economies of scale apply. Larger volume purchases (bulk orders) typically command significant per-unit discounts compared to buying single units or small batches. The setup costs for manufacturing are distributed across more units.

Market Factors: Broader economic conditions, fluctuations in the cost of raw materials (especially metals like steel, copper, and tin for bronze), energy costs, and global supply chain dynamics can influence the base price over time.

Supplier and Region: Pricing can vary between different manufacturers or distributors based on their production costs, overheads, brand positioning, and geographic location. Import/export duties and logistics costs also play a role in the final landed price for the buyer.

Service and Support: While often separate from the unit price, comprehensive after-sales support, extended warranties, or expedited delivery options may come at an additional cost but represent value-added services.

For precise and competitive pricing tailored to a specific application's requirements, direct consultation with the manufacturer or authorized distributor is always recommended.

Supplier of Worm Gear Drive WE12

LYRADRIVE stands as a leading specialist manufacturer of high-performance worm gear drives, including the robust WE12 model. Our commitment revolves around engineering excellence and stringent quality control, ensuring every drive unit meets rigorous international standards for performance, durability, and safety. Utilizing state-of-the-art manufacturing facilities and premium materials, LYRADRIVE delivers WE12 drives renowned for their reliability and efficiency in the most demanding industrial scenarios. We pride ourselves on offering more than just a product; our experienced engineering team works closely with clients to understand unique application challenges. This collaborative approach allows us to provide expert technical support and develop tailored solutions, whether involving standard configurations or specific customizations, optimizing the WE12's integration for maximum operational efficiency and longevity. LYRADRIVE's dedication to continuous innovation and customer satisfaction solidifies our position at the forefront of drive technology, making us the preferred partner for businesses seeking dependable, high-torque rotary motion solutions globally.