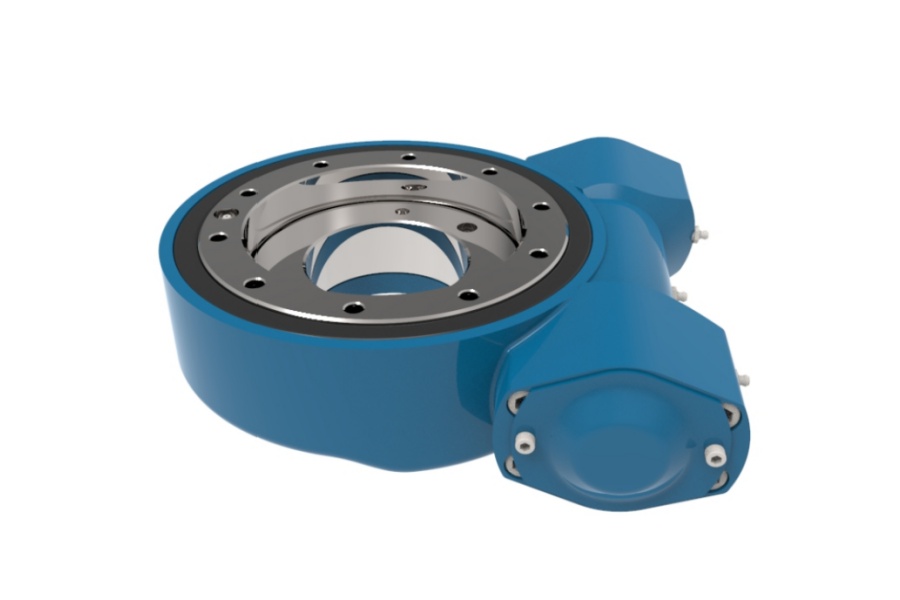

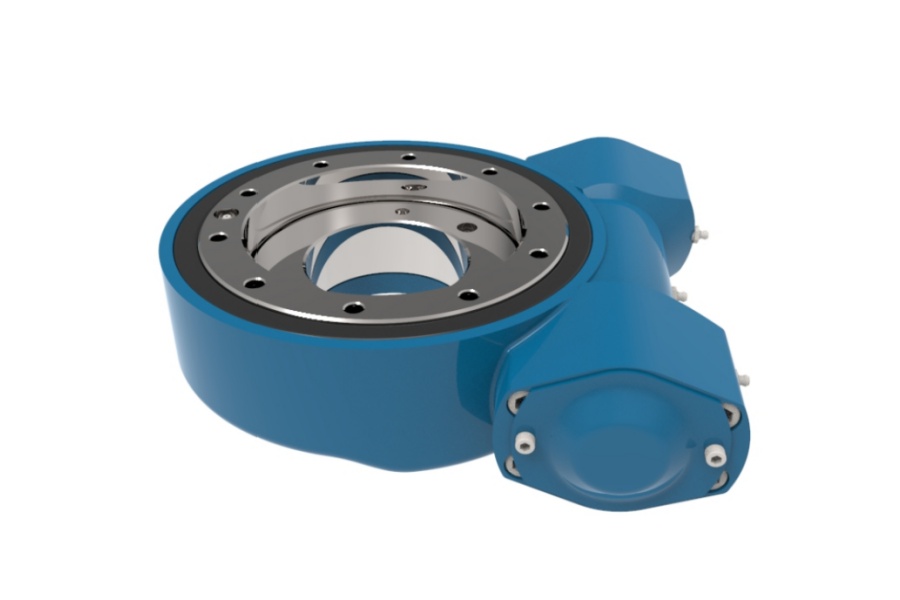

Worm Gear Drive WE7 High Torque Slew Drive

What is Worm Gear Drive WE7

Worm Gear Drive WE7 represents the pinnacle of compact, high-efficiency rotary drive systems. This fully integrated unit combines a hardened steel worm screw, wear-resistant bronze wheel gear, and heavy-duty bearings within a rigid housing. Designed as a complete mechanical package, it delivers 3.5 kN.m output torque, 14.2 kN.m tilt moment capacity, and 20 kN.m static holding torque. With an IP65-rated enclosure and 47:1 gear ratio, it operates reliably in harsh environments requiring ≤0.15° tracking accuracy. The WE7 series eliminates complex assembly through its unitized design while providing unmatched load-handling versatility.

How to Choose Between External and Internal Gear Slew Drives

Selecting between external and internal gear configurations depends on critical application parameters:

External Gears deliver higher torque density and better heat dissipation. Ideal for mining equipment and heavy-duty positioning systems where 14.2 kN.m tilt moments are encountered.

Internal Gears offer compact installation envelopes and superior contamination protection. Optimal for space-constrained applications like aerial work platforms.

Both designs in the WE7 series feature ZA/ZK tooth profiles for 98%+ meshing efficiency. Choose external gears when facing extreme moment loads; opt for internal gears when IP65 dust/water resistance is paramount.

Worm Gear Drive WE7 Key Features

Triple-Load Capacity: Simultaneously manages 220 kN axial, 90 kN radial, and 14.2 kN.m moment loads.

Zero-Maintenance Security: Self-locking mechanism prevents back-driving without brakes.

Environmental Resilience: IP65 sealing with dual-lip seals (WEA7/WEB7 models) for mining/drilling applications.

Precision Motion Control: ≤0.15° tracking accuracy through ground gear teeth.

Drive Flexibility: Direct coupling with hydraulic motors or electric servos.

Optimized Efficiency: Bronze-aluminum gear (CuAl10Fe5Ni5) paired with case-hardened 17CrNiMo6 steel worm.

Compact Integration: 32 kg unit replaces complex drivetrain assemblies.

Worm Gear Drive WE7 Industrial Applications

Aerial Work Platforms: Provides failsafe rotation under 20 kN.m holding torque.

Mining & Drilling Rigs: Handles shock loads in rotary drill heads and conveyor positioning.

Industrial Positioners: Enables precise ≤0.15° indexing in welding automation.

Material Handling: Rotates heavy loads in foundry equipment with 220 kN axial capacity.

Defense Systems: Self-locking security for radar pedestals in naval environments.

Factors Influencing Worm Gear Drive WE7 Pricing

Torque Tiering: Units configured for >20 kN.m holding torque incur 18-22% cost premium.

Sealing Level: IP65 standard; IP68 sealing (WEA7/WEB7) adds 15% cost.

Gear Precision: AGMA 12 standard gearing vs. precision-ground AGMA 14 (affects tracking accuracy).

Material Upgrades: Stainless steel housings for corrosive environments increase cost 25%.

Drive Integration: Pre-mounted servo motors or hydraulic adapters impact pricing.

Certifications: Explosion-proof or MIL-SPEC validation adds 30%+ to base cost.

Volume Economics: Orders >50 units reduce per-unit cost by 12-18%.

Supplier of Worm Gear Drive WE7

LYRADRIVE engineers industrial-grade Worm Gear Drive WE7 solutions for mission-critical applications worldwide. With ISO 9001-certified manufacturing and in-house R&D facilities, we deliver drives exceeding AGMA Class 12 precision standards. Our technical support team provides lifecycle maintenance guidance and custom engineering for specialized load requirements. Global distribution centers ensure rapid delivery of standard and application-optimized WE7 variants, backed by 24-month performance warranties.