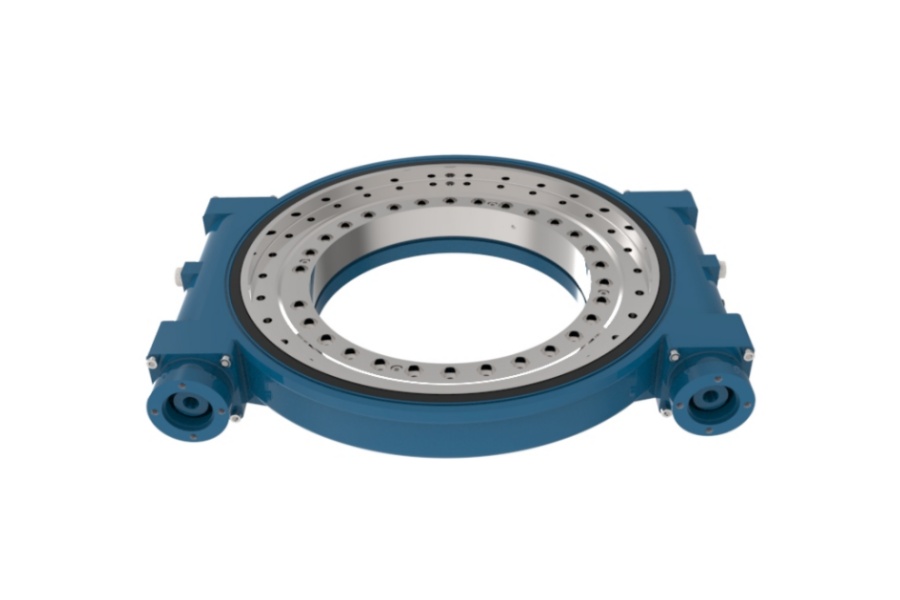

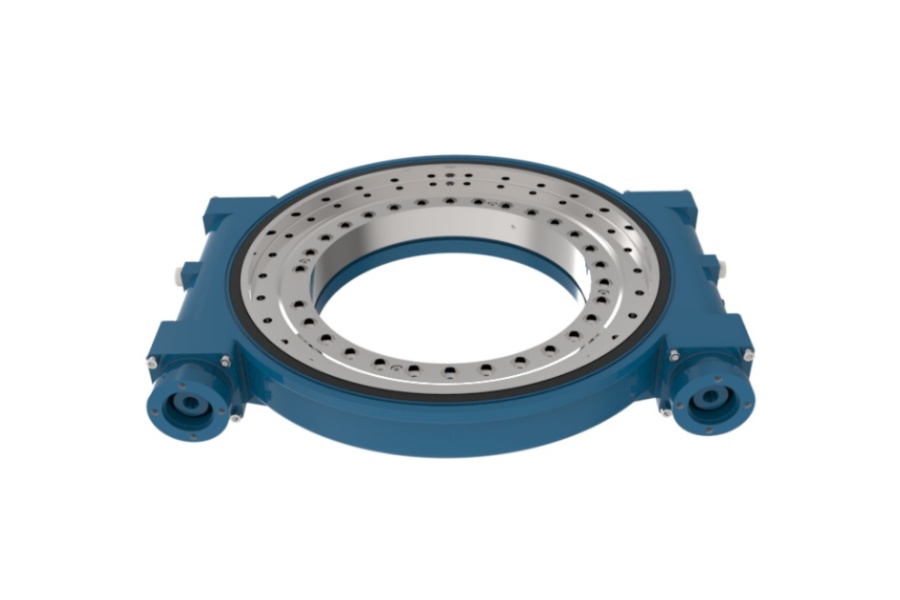

Double Worm Slew Drive Precision Power Rotation

What is Double Worm Slew Drive

Double Worm Slew Drive is a compact rotary actuator combining a slewing bearing with two opposing worm gears meshing with a central wheel gear. This dual engagement eliminates backlash, symmetrically distributes load, and significantly boosts torque capacity and system stiffness compared to single-worm designs.

Boosting Torque in Worm Gear Slew Drives

Dual Load Sharing: Two worms double torque capacity without doubling input power.

Optimized Gear Design: Lower lead angles increase mechanical advantage.

High-Strength Materials: Hardened steel worms (e.g., 17CrNiMo6) paired with wear-resistant bronze gears (e.g., CuAl10Fe5Ni5).

Precision Manufacturing: Accurate tooth profiles and perfect worm alignment ensure optimal load distribution.

Advanced Lubrication: High-viscosity EP grease reduces friction under heavy loads.

Worm and Wheel Gear Mesh Service Life

Key factors influencing lifespan:

Contact Stress: Primary driver of pitting fatigue. Double worms reduce stress per tooth.

Wear Mechanisms: Scuffing (adhesive wear) and abrasive wear are major concerns.

Lubrication Quality: Critical for separating metal surfaces and preventing scuffing. Contamination control is vital.

Alignment & Rigidity: Misalignment causes edge loading, drastically accelerating failure.

Material Compatibility: Hard steel worm + softer bronze wheel is optimal for wear resistance.

Double Worm Slew Drive Characteristics

Zero Backlash: Opposing worms preload the mesh.

High Rigidity: Resists deflection under heavy moments.

High Torque Density: Superior power in a compact package.

Smooth & Quiet Operation: Distributed contact minimizes vibration.

Self-Locking Potential: Holds position without external brakes.

Redundancy: One worm can often maintain limited operation if the other fails.

Double Worm Slew Drive Applications

Precision Solar Trackers (Dual-Axis)

Satellite Communication (SATCOM) Antennas

Radar Systems (Ground, Naval, Airborne)

Heavy Payload Robotics

Medical Equipment (LINACs, Proton Therapy)

Telescopes & Astronomical Instruments

Industrial Automation (Indexing Tables, Positioners)

Defense Systems (Weapon Stations)

Factors Affecting Double Worm Slew Drive Price

Size & Load Rating: Larger size/higher capacity = higher cost.

Bearing Type & Precision: Crossed roller/triple-row bearings cost more than ball types. Higher precision adds expense.

Gear Complexity: Precision grinding of hardened worms and large bronze wheel gears is costly. High gear quality classes (e.g., AGMA 14) increase price.

Materials: Alloy steel worms, high-performance bronze gears, and stainless steel components cost more.

Motors & Brakes: Integrated servo motors and brakes significantly impact cost.

Precision & Backlash: Achieving guaranteed zero backlash requires premium manufacturing.

Sealing & Protection: High IP ratings or corrosion protection add cost.

Customization: Non-standard designs incur engineering fees.

Quantity: Unit cost decreases with volume.

Supplier of Double Worm Slew Drive

LYRADRIVE specializes in engineering and manufacturing high-performance Double Worm Slew Drives. We focus on delivering robust solutions with zero backlash, exceptional rigidity, and reliable torque for critical applications in solar, defense, medical, and industrial automation. Our commitment is to precision, quality, and tailored support for optimal system performance.