Worm Slewing Drives Power Transmission Solutions

What is Worm Slewing Drive

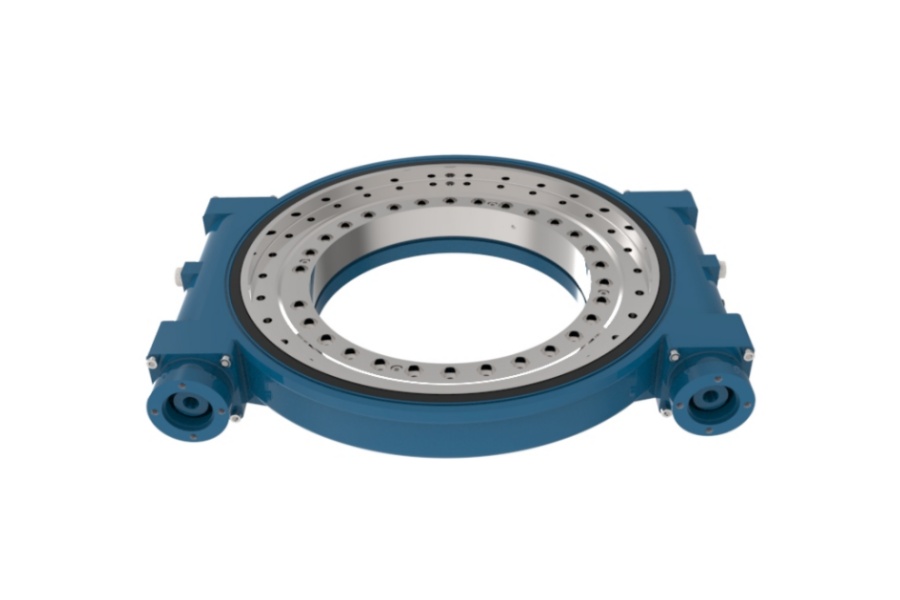

Worm Slewing Drive is an integrated mechanical assembly comprising a hardened steel worm screw engaging with a large-diameter worm wheel (typically forged steel or ductile iron) that is mechanically fused to the outer or inner ring of a slewing bearing. This unique configuration transforms the rotational input from the worm shaft—usually driven by an electric, hydraulic, or pneumatic motor—into slow-speed, high-torque rotary output with an inherent self-locking characteristic. The slewing bearing component provides robust radial, axial, and moment load support for the rotating platform or structure. The worm gear set’s typical 90-degree shaft orientation allows for flexible motor mounting, while the self-locking nature prevents back-driving under load, making it ideal for applications requiring secure positioning without external brakes. Engineered for reliability in harsh environments, these drives offer high reduction ratios (often 5:1 to 100:1+) within a single compact stage.

How to Enhance Worm Gear Load Capacity and Transmission Efficiency

Improving the load capacity and efficiency of the worm gear set within a slewing drive is critical for performance and longevity. Key strategies involve material science, precision engineering, and advanced tribology:

Premium Material Selection & Heat Treatment: Utilizing high-strength alloy steels for the worm shaft (e.g., 42CrMo, 17CrNiMo6) and worm wheel (e.g., 42CrMo, ductile iron QT700-2). Implementing deep case carburizing, carbonitriding, or induction hardening on the worm thread achieves surface hardness of HRC 58-62 with a tough core (HRC 28-35 for the wheel). This enhances surface durability against pitting and scuffing while maintaining core resilience against shock loads.

Precision Tooth Geometry Optimization: Employing modern "K" profile or modified involute tooth geometries on the worm and wheel. This promotes optimized line contact over point contact, significantly increasing load distribution and reducing localized contact stress. Precise CNC grinding of the worm thread post-heat treatment ensures micron-level accuracy for smooth meshing.

Advanced Surface Engineering: Applying specialized surface treatments like phosphating, specialized coatings (e.g., molybdenum disulfide, DLC), or superfinishing (Ra ≤ 0.2 μm) to the worm thread and wheel tooth flanks. This minimizes friction coefficients, reduces adhesive wear risk (scuffing), and enhances lubricant film formation and retention.

Optimized Lubrication Design: Utilizing high-performance synthetic EP (Extreme Pressure) greases or oil bath systems formulated specifically for high-sliding worm gears. Incorporating efficient lubrication grooves/pockets within the housing and optimized oil splash patterns ensures adequate lubricant reaches the critical mesh zone under all operating angles, reducing friction and wear.

Precision Alignment & Rigid Housing: Ensuring absolute concentricity and perpendicularity between worm and wheel axes through precision machining of the drive housing and bearing bores. Using rigid housing designs (often nodular iron) minimizes deflection under load, maintaining optimal tooth contact patterns and preventing edge loading. Preloaded tapered roller bearings support the worm shaft to eliminate axial play.

Worm and Wheel Meshing Lifetime Analysis

Predicting and extending the service life of the worm-wheel mesh requires analyzing failure modes and implementing design countermeasures:

Primary Failure Modes:

Wear & Scuffing (Adhesive Wear): Caused by breakdown of the lubricant film under high sliding velocities and contact pressures, leading to material transfer between surfaces. Mitigated by coatings, lubricant selection, and optimized surface finish.

Pitting (Surface Fatigue): Subsurface shear stresses exceeding material endurance limits cause micro-cracks, leading to surface material flaking. Addressed by hardened surfaces, refined microstructures, reduced contact stress (optimized profile), and high cleanliness steel.

Bending Fatigue: Overload or shock loads causing tooth root fracture. Prevented by adequate tooth root fillet design, material toughness, and avoiding gross overloads.

Thermal Failure: Excessive friction generating heat beyond the lubricant's capacity, leading to viscosity breakdown, accelerated wear, and potential seizure. Managed via efficient heat dissipation (finned housings, cooling fans), adequate lubricant volume, and minimizing friction.

Lifetime Calculation Factors: Service life is modeled using modified AGMA/ISO standards considering:

Applied Torque & Load Spectra: Peak, average, and dynamic loads.

Material Properties: Hardness, bending fatigue strength, pitting resistance.

Lubrication Effectiveness: Film thickness parameter (Λ ratio).

Operating Environment: Temperature, contamination levels.

Gear Geometry: Size, pressure angle, helix angle, contact ratio.

Manufacturing Quality: Accuracy grade (e.g., DIN 5).

Life Extension Strategies: Implementing the load capacity/efficiency enhancements listed above directly correlates to extended meshing life. Regular oil/grease analysis and proactive maintenance are critical operational factors.

Characteristics of Worm Slewing Drives

These integrated drives offer unique advantages for specific motion control needs:

High Torque Density & Compact Design: Delivers exceptional output torque relative to footprint due to the high reduction ratio achievable in a single stage.

Inherent Self-Locking: The worm gear's high friction angle prevents back-driving under static loads (efficiency <50%), eliminating the need for external brakes in holding positions. Note: Dynamic reversibility depends on lead angle and friction.

Smooth & Quiet Operation: Precision meshing and optimized profiles result in low vibration and noise levels, suitable for sensitive environments.

High Load Capacity: Integrates robust slewing bearing support for combined radial, axial, and moment loads directly at the output.

90-Degree Shaft Configuration: Simplifies motor mounting perpendicular to the output axis, saving space.

High Reduction Ratios: Achieves significant speed reduction (5:1 to over 100:1) in a single compact unit.

Robust Construction & Sealing: Heavy-duty housings and multi-lip seals protect internal components from dust, water, and corrosive elements (common IP65/IP66 ratings).

Bi-Directional Operation: Functions equally well for clockwise and counter-clockwise rotation.

Applications of Worm Slewing Drives

Their unique characteristics make them ideal for numerous demanding applications:

Material Handling: Rotating heavy-duty industrial robots, palletizers, stacker-reclaimers, and rotary feeders.

Construction Equipment: Positioning concrete mixer drums, rotating drilling rig masts, and articulating heavy attachments.

Packaging Machinery: Indexing rotary tables, turntables for filling, capping, and labeling.

Aerial Work Platforms: Rotating the boom or platform on cherry pickers and telescopic handlers.

Defense & Aerospace: Positioning radar antennae, missile launchers, and satellite communication dishes.

Medical Equipment: Rotating components within imaging systems (CT/MRI) or radiation therapy devices.

Stage & Entertainment: Controlling the movement of heavy lighting rigs, video screens, and theatrical scenery.

Agricultural Machinery: Adjusting the angle of large sprayer booms or positioning harvesting equipment.

Marine & Offshore: Operating deck cranes, hatch covers, and winch positioning systems.

Factors Influencing Worm Slewing Drive Price

The cost of a worm slewing drive varies significantly based on its specifications and manufacturing quality:

Size & Torque Rating: Larger diameter slewing rings and higher torque capacities require more material and heavier machining, exponentially increasing cost.

Slewing Bearing Type & Complexity: Integrated bearing type (single-row ball, cross roller, three-row roller), size, and load rating are major cost drivers. Higher precision bearings add cost.

Worm Gear Specifications: Worm/wheel diameter, module/pitch, gear ratio, material grades (alloy steel vs. ductile iron), and required heat treatment depth/specification significantly impact cost. Hardened and ground worms are costlier.

Precision & Quality Grade: Tighter manufacturing tolerances (e.g., DIN 5 vs DIN 7), finer gear tooth finishing (ground vs. hobbed), and stricter runout/backlash requirements necessitate more complex processes and inspection, increasing price.

Housing Material & Complexity: Cast nodular iron housings offer best rigidity but cost more than fabricated steel. Complex internal geometries for lubrication or cooling add machining cost.

Sealing & Protection: Higher IP ratings (IP66/IP69K) require more sophisticated sealing systems and validation testing. Corrosion protection (coatings, stainless components) adds cost.

Motor Mounting Interface & Accessories: Integrated motor flanges, adapters, brake provisions, encoders, and limit switches add to the base price.

Customization: Non-standard sizes, special shaft configurations, unique mounting patterns, or specific material certifications significantly increase development and production costs.

Brand Reputation & Engineering Support: Drives from established manufacturers with proven reliability, extensive engineering resources, and application support command premium pricing.

Quantity & Supply Chain: Unit costs decrease with volume production. Raw material (steel) fluctuations and logistics also affect pricing.

Supplier of Worm Slewing Drives

For engineers and project managers seeking reliable, high-performance motion solutions, LYRADRIVE delivers precision-engineered Worm Slewing Drives built for demanding industrial environments. We specialize in custom and standard drives utilizing premium alloy steel worms (carburized & ground to HRC 58-62) and high-strength worm wheels, meticulously paired with robust slewing bearings for optimal load handling and longevity. Our commitment to advanced manufacturing—including optimized tooth profiling, precision grinding, and rigorous quality control—ensures smooth operation, high efficiency, and extended service life. LYRADRIVE provides comprehensive technical support from selection through installation, offering tailored solutions for solar tracking, heavy-duty automation, material handling, and beyond. Trust LYRADRIVE for the integrated drive performance critical to your application's success.