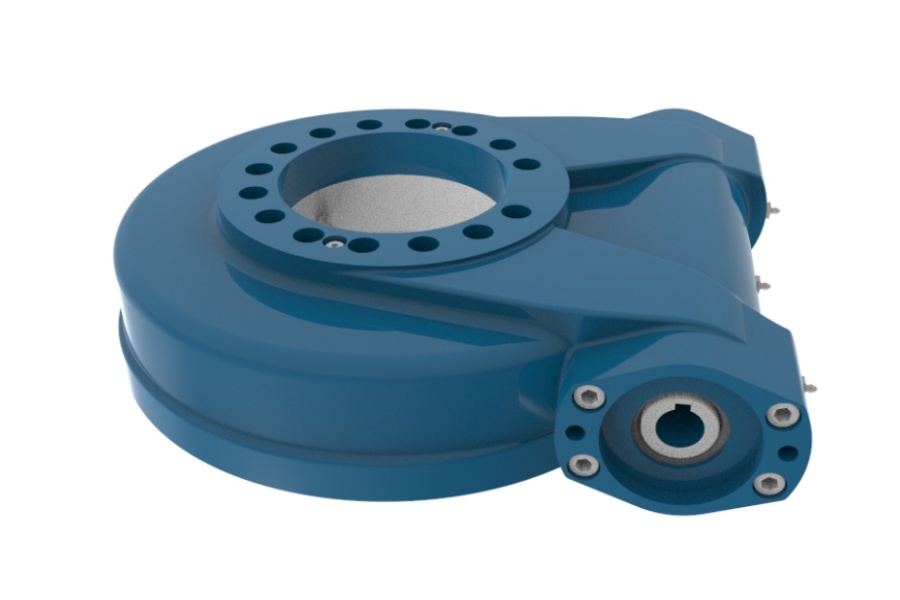

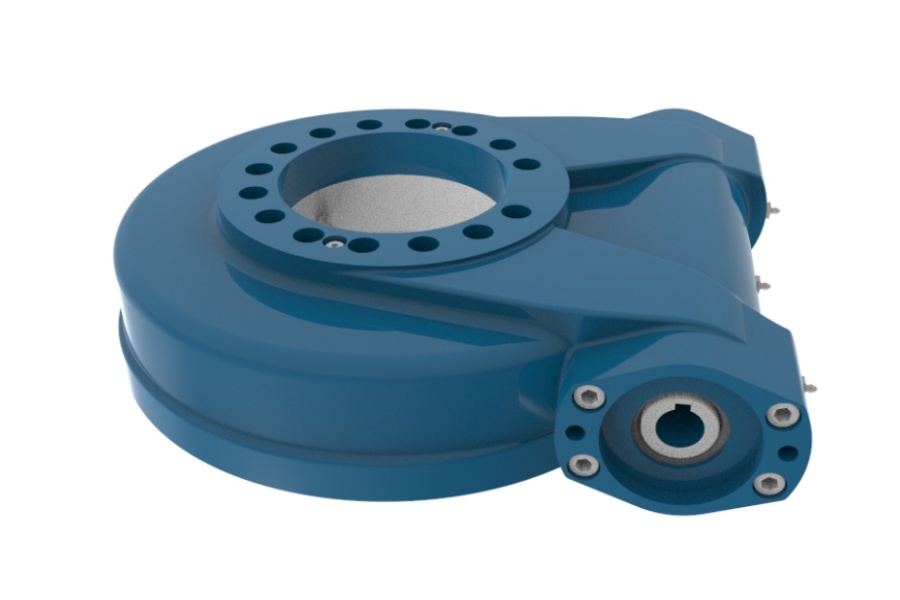

Worm Gear Drive WE9 Comprehensive Technical Guide

What is Worm Gear Drive WE9

Worm Gear Drive WE9 is a precision-engineered mechanical drive system designed for high torque transmission and reliable motion control. This integrated unit comprises a robust base housing, a precisely machined worm shaft, and a mating worm wheel. Operating within this sealed enclosure, the WE9 effectively transmits power while withstanding substantial axial loads, radial forces, and tilting moments. A critical feature of the WE9 is its inherent self-locking mechanism. This occurs due to the specific angle of the worm's threads, which creates sufficient friction to prevent the worm wheel from back-driving the worm shaft when input power ceases. This capability is paramount for safety and positional integrity in vertical lifts, hoisting, and holding applications, preventing unintended movement even under load. The drive utilizes advanced ZA or ZK tooth profiles, promoting tighter meshing and improved contact patterns, which translate to enhanced efficiency and smoother operation compared to standard worm gear designs. This optimized geometry minimizes power loss and maximizes torque transfer within the compact form factor.

Analyzing Corrosion Resistance Design in Slewing Drives

Corrosion resistance is a fundamental design consideration for slewing drives like the WE9, especially given their frequent deployment in challenging environments such as construction, mining, marine applications, and outdoor industrial settings. The WE9 incorporates several key design elements to combat corrosion effectively:

High-Performance Sealing (IP65): The foundation of corrosion protection is preventing corrosive agents like water, salt spray, chemicals, and abrasive dust from entering the drive assembly. The WE9 achieves an IP65 rating, signifying complete protection against dust ingress and protection against low-pressure water jets from any direction. This is realized through precision-machined mating surfaces, high-quality radial shaft seals (often Nitrile or Viton for chemical resistance), and specialized sealing gaskets at housing interfaces.

Protective Coatings & Surface Treatments: Critical external components, particularly the housing, undergo specific surface treatments. This typically involves a multi-stage process: thorough cleaning and degreasing, phosphating or another conversion coating for enhanced paint adhesion, and the application of a durable, corrosion-resistant paint system (e.g., epoxy or polyurethane paints). Internal components like the worm and wheel may utilize corrosion-resistant alloys or receive specialized coatings like black oxide or phosphate coatings for added protection against internal condensation or lubricant breakdown byproducts.

Corrosion-Resistant Materials: Where feasible and appropriate for strength requirements, components are manufactured from inherently corrosion-resistant materials such as stainless steel (e.g., for fasteners, shafts, or specific structural elements) or aluminum alloys with appropriate surface treatments.

Lubrication Management: The correct lubricant acts as a protective barrier. The WE9 is filled with high-quality grease specifically formulated not only for load-bearing and wear protection but also to possess corrosion-inhibiting additives. The sealing system ensures this lubricant remains contained while contaminants are excluded. Regular maintenance intervals specified by LYRADRIVE are crucial to replenish these protective additives and purge any potential contaminants that may breach seals over time.

Design for Drainage: Housing design incorporates features to prevent water pooling on or around the unit, such as sloped surfaces or strategically placed drain points, reducing the potential for prolonged corrosive exposure.

Worm Gear Drive WE9 Features

The Worm Gear Drive WE9 distinguishes itself through a suite of robust features engineered for demanding performance:

Exceptional Torque Capacity: Engineered for high power density, the WE9 delivers significant output torque (8 kN.m) and can withstand substantial tilting moments (36.5 kN.m) and holding torque (38.7 kN.m), enabling it to handle heavy loads with stability.

Inherent Self-Locking Capability: The optimized worm geometry provides reliable self-locking, preventing back-driving under load. This intrinsic safety feature is critical for applications like lifts, cranes, and positioning systems where unintended movement poses risks.

High Efficiency & Precision: Utilizing advanced ZA/ZK tooth profiles ensures efficient power transmission and minimizes energy loss. Combined with a high transmission ratio (62:1), it delivers precise rotational control with a tracking accuracy of ≤0.15°, essential for accurate positioning.

Superior Sealing & Protection (IP65): The integrated sealing system provides complete dust-tightness and protection against water jets, ensuring reliable operation in dirty, wet, or outdoor environments. This significantly enhances longevity and reduces maintenance needs.

Robust Construction & Durability: Manufactured from high-strength materials and subjected to rigorous quality control, the WE9 is built to endure the harsh conditions of industrial use, offering exceptional longevity and resistance to wear.

Versatile Mounting & Drive Compatibility: Designed for flexible integration, the WE9 housing facilitates straightforward mounting. It readily interfaces with various drive sources, including hydraulic motors and electric motors (geared or direct), offering adaptability to different power systems.

Compact and Integrated Design: The unit consolidates the worm, wheel, bearings, and seals into a single, space-saving housing, simplifying installation and reducing the overall system footprint compared to component-based solutions.

Optimized Bearing Arrangement: Strategically selected and positioned bearings (typically combining tapered roller bearings for radial/axial loads and potentially angular contact bearings) efficiently manage the complex combination of radial, axial, and tilting moment loads.

Worm Gear Drive WE9 Applications

The combination of high torque, self-locking, durability, and environmental protection makes the Worm Gear Drive WE9 exceptionally versatile across numerous heavy-duty industries:

Aerial Work Platforms (Boom Lifts): Provides the essential slewing motion for lifting booms and positioning baskets or platforms with precision and inherent safety (self-locking) at height.

Mining Equipment: Powers critical functions in rugged mining machinery, such as the slewing mechanism for drill rig masts, conveyor positioning, and hoist drives, where reliability under extreme loads and contamination is paramount.

Material Handling & Industrial Tipping Mechanisms: Used in applications like rotating dump bodies, mixer drums, industrial hoppers, and foundry equipment for controlled tipping, pouring, or mixing operations requiring high torque and positional hold.

Construction Machinery: Integral to various construction equipment requiring robust rotation, including compact track loaders (for attachments), concrete pump line rotation, crane jib rotation, and screed positioning.

Renewable Energy: Employed in solar tracker systems to precisely orient photovoltaic panels towards the sun throughout the day, leveraging its accuracy and holding capability.

Automation & Robotics: Provides precise rotational positioning and high holding torque for automated assembly lines, robotic arms, indexing tables, and other machinery requiring reliable and accurate motion control.

Marine & Offshore Equipment: Used in deck machinery, crane rotation on vessels, and hatch cover mechanisms, benefiting from its corrosion resistance and ability to handle heavy loads in challenging saltwater environments.

Agricultural Machinery: Powers functions like grain bin sweeps, auger positioning, and specialized implement rotation where durability and resistance to dust/moisture are essential.

Factors Influencing Worm Gear Drive WE9 Price

The price of a Worm Gear Drive WE9 unit is not fixed and can vary significantly based on several key factors:

Specification & Configuration: The core specifications heavily impact cost. Units requiring higher output torque, higher tilting moment capacity, or specific transmission ratios (like the standard 62:1) may involve more robust materials or larger components. The choice between standard and custom tooth profiles (ZA vs. ZK) can also play a role.

Material Selection & Special Treatments: Standard units use high-quality materials. However, applications demanding enhanced corrosion resistance (e.g., marine, chemical) may require stainless steel components, specialized coatings (beyond standard paint), or specific surface hardening treatments, all adding to the cost. The choice of bearing types and grades also factors in.

Sealing Requirements: While IP65 is standard, applications needing submersible capability (IP67/IP68) or resistance to specific chemicals or extreme temperatures require specialized seals (e.g., Viton, PTFE) and potentially modified sealing designs, increasing the price.

Customization Level: Any deviation from the standard WE9 design constitutes customization. This includes:

Unique mounting flanges or bolt patterns.

Special shaft configurations (hollow shafts, keyways, splines, different shaft diameters/lengths).

Integration of specific brakes (disc, failsafe).

Custom paint colors or special markings.

Modified lubrication ports or systems.

Integration of sensors (e.g., position, temperature, rotation).

Drive Source Integration: While designed for easy coupling, the cost may differ if the unit is supplied pre-assembled with a specific hydraulic motor or electric motor/gearbox combination versus supplied bare for customer mounting.

Order Quantity & Production Volume: Larger volume orders typically benefit from economies of scale, reducing the unit cost compared to single-unit or small-batch purchases.

Market Factors & Raw Material Costs: Fluctuations in the global prices of steel, alloys, bearings, and other raw materials directly impact manufacturing costs. General economic conditions and supply chain dynamics also influence pricing.

Supplier Value-Add: Reputable manufacturers like LYRADRIVE invest significantly in engineering expertise, rigorous quality control (testing, inspection), technical support, warranty coverage, and reliable after-sales service. This value proposition is reflected in the price compared to lesser-known suppliers.

Supplier of Worm Gear Drive WE9

LYRADRIVE stands as a premier designer and manufacturer of high-performance slewing drives, including the robust Worm Gear Drive WE9. We leverage advanced engineering principles, state-of-the-art manufacturing facilities, and stringent quality control processes to produce drives that meet the most demanding industrial standards for torque, precision, durability, and environmental protection. Our commitment extends beyond manufacturing; our experienced engineering and sales teams collaborate closely with clients to understand their unique application challenges. This collaborative approach allows us to offer not only standard WE9 units but also provide expert customization and application engineering support, ensuring the optimal drive solution integrates seamlessly into your machinery. LYRADRIVE continuously invests in research and development, focusing on material science, gear design optimization, and sealing technology to enhance the performance, efficiency, and lifespan of the WE9 and our broader product range. We are dedicated to delivering exceptional value through reliable products, responsive technical support, and a partnership approach focused on your operational success. Contact LYRADRIVE today to discuss your specific Worm Gear Drive WE9 requirements and experience the difference expertise makes.