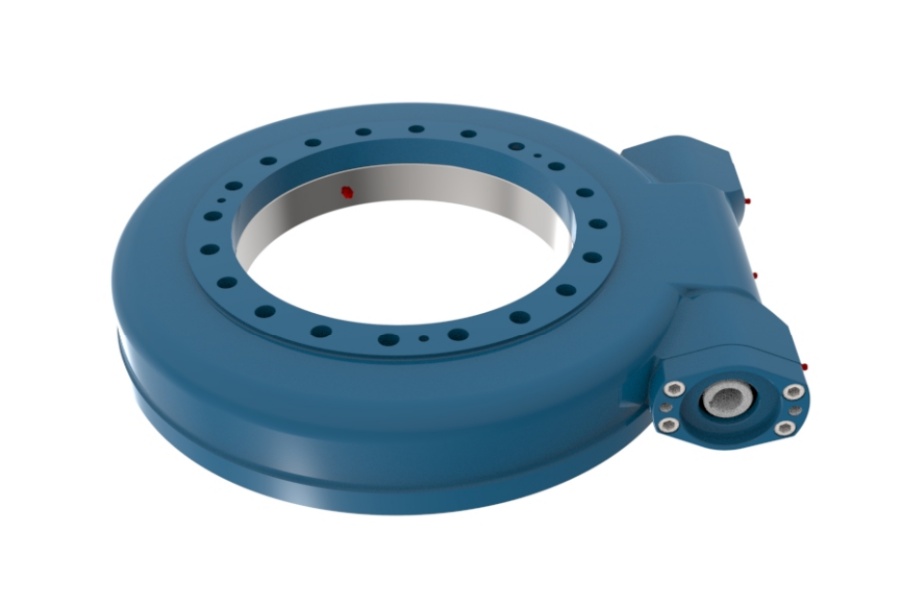

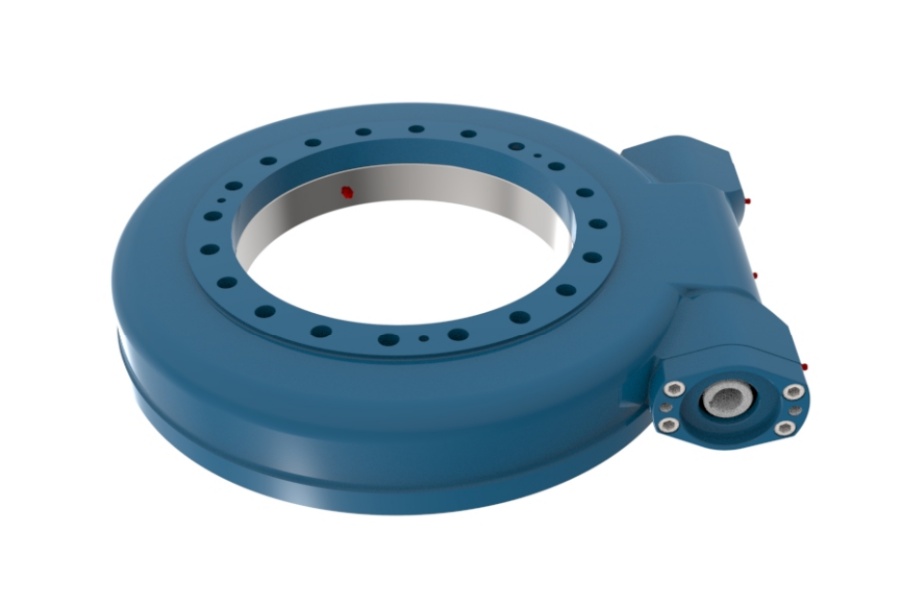

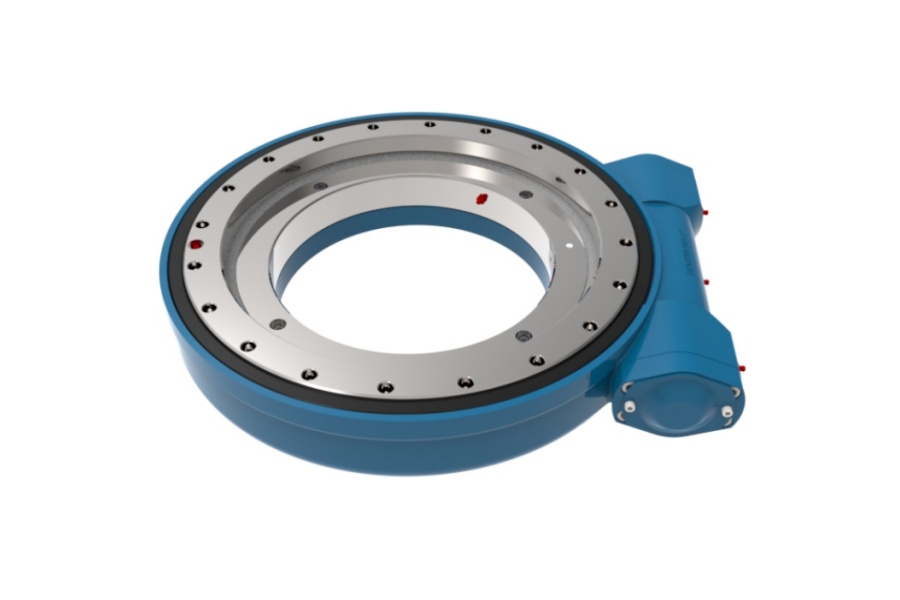

Worm Gear Drive WE17 for Demanding Industrial Application

What is Worm Gear Drive WE17?

Worm Gear Drive WE17 is a specific configuration of worm gear reducer characterized by its size (denoted by the frame size "WE17"), construction, and performance capabilities. This type of drive consists of a hardened steel worm (the input screw) that meshes precisely with a bronze or phosphor-bronze worm wheel (the output gear). The unique sliding action within this meshing creates high torque multiplication and an inherent self-locking capability in many configurations, preventing back-driving. The WE17 designation typically refers to a standardized industrial frame size, ensuring interchangeability and mounting compatibility within defined power and torque ranges. These drives are designed for durability and long service life under continuous operation in challenging industrial environments.

Heavy-Duty Worm Gearbox WE17

The Heavy-Duty Worm Gearbox WE17 is the core physical unit housing the Worm Gear Drive WE17 mechanism. Engineered for maximum resilience, this gearbox features a rugged cast iron or high-strength aluminum alloy housing that provides exceptional rigidity and vibration dampening. Key design elements focus on handling substantial shock loads and continuous high torque. High-capacity tapered roller bearings or specialized thrust bearings are employed to manage significant radial and axial forces efficiently. The gearbox incorporates advanced sealing systems, often involving multiple lip seals, labyrinth seals, or even grease purge systems, to prevent ingress of contaminants like water, dust, and particulate matter common in industrial settings. Large oil reservoirs facilitate effective lubrication and heat dissipation, while specialized synthetic lubricants ensure smooth operation across wide temperature ranges. Robust input shaft configurations (solid shafts, hollow shafts with keyways or shrink discs) and output flanges or shafts are standard, ensuring secure power transmission to driven equipment.

Worm Gear Drive WE17 Port Crane Application

The WE17 Port Crane Application showcases the drive's capability in one of the most demanding environments. Worm Gear Drives WE17 are fundamental components in various crane functions:

Slewing Mechanism: Providing the precise, controlled rotational movement of the crane's upper structure (house) relative to its base. The high torque output and inherent braking effect (self-locking potential) of the WE17 drive are critical for safe, stable positioning of heavy loads, even in windy conditions.

Luffing Mechanism: Controlling the raising and lowering of the crane's boom. The WE17 drive delivers the necessary torque to manage the significant leverage and weight of the boom assembly and its load smoothly and reliably.

Gantry Travel Drives: Powering the wheels of rubber-tired gantry (RTG) cranes or rail-mounted gantry cranes (RMG) for container movement within the yard. The robustness of the WE17 gearbox handles the inertia, shock loads from uneven surfaces or rail joints, and the constant start-stop cycles.

In port cranes, the WE17 drive's ability to operate reliably under extreme loads, resist harsh environmental factors (salt spray, humidity, dust), and provide controlled, low-speed, high-torque motion is indispensable for safety and productivity.

Worm Gear Drive WE17 Characteristics

Worm Gear Drive WE17 is defined by a distinct set of performance and construction characteristics:

High Torque Density: Delivers exceptionally high output torque relative to its frame size, enabling compact machinery design.

Right-Angle Configuration: Efficiently changes the direction of shaft rotation by 90 degrees within a single compact unit.

Smooth & Quiet Operation: The enveloping design of the worm and wheel mesh, combined with precision manufacturing, results in low vibration and noise levels.

High Reduction Ratios: Achieves significant speed reduction and torque multiplication in a single reduction stage, often ranging from 5:1 up to 100:1 or higher.

Inherent Self-Locking (Potential): In many standard ratio configurations, the drive angle prevents the output shaft from back-driving the input worm, acting as a mechanical brake. (Note: This feature depends on the specific ratio and lead angle; high-efficiency designs may not self-lock).

Shock Load Tolerance: The sliding contact design and robust construction allow it to absorb and withstand substantial shock and impact loads better than some other gear types.

Durability & Long Life: Use of hardened steel worms and bronze wheels, large bearings, ample lubrication, and sturdy housings contribute to exceptional longevity, even under continuous duty cycles.

Efficiency: While inherently lower than precision helical or planetary gears due to sliding friction, modern WE17 designs optimize efficiency through high-quality materials, precise machining, and optimized lubrication. Efficiency typically increases with higher ratios.

Maintenance Friendly: Designed for ease of lubrication (oil fill/drain plugs, level indicators) and inspection.

Worm Gear Drive WE17 Applications

Beyond port cranes, Worm Gear Drive WE17 finds extensive use across industries requiring robust, right-angle power transmission:

Material Handling: Conveyor drives (especially heavy-duty belt conveyors, bucket elevators), palletizers, automated storage and retrieval systems (AS/RS), stacker-reclaimers.

Construction Equipment: Concrete mixers, screed drives, winches, hoists, conveyor drives on pavers and crushers.

Food & Beverage Processing: Mixers, agitators, conveyors (chain, belt, screw), packaging machinery, bottling lines – often requiring specific hygiene-compliant finishes.

Industrial Machinery: Rotary tables, indexing drives, large valve actuators, kiln and dryer drives, extruders, rolling mill auxiliary drives.

Water & Wastewater Treatment: Aerator drives, mixer drives, screen drives, pump jacks.

Mining & Minerals: Crushers, feeders, screens, rotary kiln drives.

Agriculture: Grain augers, mixer wagons, large irrigation systems.

Stage & Entertainment: Heavy-duty stage lifts, turntables, and rigging systems requiring controlled movement.

Factors Influencing Worm Gear Drive WE17 Pricing

The cost of a Worm Gear Drive WE17 is not fixed and varies significantly based on several key factors:

Materials: The quality and specific grades of materials used significantly impact cost. High-grade alloy steel for the worm (e.g., 16MnCr5, 20MnCr5 hardened and ground), premium bronze alloys (e.g., centrifugal cast CuSn12Ni2-C) for the wheel, and the type of housing material (GGG40 cast iron vs. aluminum) are major cost drivers.

Precision & Quality of Manufacturing: The level of precision grinding on the worm threads and wheel teeth, bearing quality (brand and precision class), and overall manufacturing tolerances directly affect performance, noise, efficiency, lifespan, and price.

Gear Ratio: Higher reduction ratios generally require more complex machining of the worm wheel, potentially increasing cost.

Housing Design & Complexity: Standard cast housings are cost-effective. Custom housings, specialized cooling fins, integrated mounting flanges, or specific sealing arrangements add cost.

Input/Output Configurations: Standard solid shafts are economical. Hollow shafts, keyed outputs, flanged outputs, or specialized couplings (shrink discs, locknuts) increase the price. The type and rating of the input coupling (e.g., IEC adapter, C-face flange) also contribute.

Efficiency & Performance Class: Drives engineered for higher mechanical efficiency or specific low-backlash requirements involve tighter tolerances and potentially special coatings or surface treatments, commanding a premium.

Thermal Capacity & Cooling Options: Standard units rely on natural convection. Applications requiring higher power density or continuous duty in hot environments might need larger housings, cooling fins, fan cooling, or even water-jacketed housings, adding cost.

Lubrication System: Standard splash lubrication is common. For critical applications, forced lubrication systems or specialized oil filtration add expense.

Sealing Requirements: Standard lip seals suffice for many applications. Demanding environments (submersion risk, high dust, chemical exposure) necessitate more expensive labyrinth seals, multiple lip seals, or mechanical seals.

Brand Reputation & Certifications: Established manufacturers with proven reliability, extensive testing, and industry certifications (ISO, ATEX, etc.) typically command higher prices.

Order Volume & Customization: Large volume orders often benefit from economies of scale. Conversely, highly customized WE17 drives (special mounting, paint, shaft dimensions, materials) incur significant engineering and setup costs.

Geographic Market & Supply Chain: Local manufacturing, import duties, and logistics costs influence the final price in different regions.

Reliable Worm Gear Drive WE17 Supplier

LYRADRIVE is a prominent global supplier specializing in high-performance Worm Gear Drive WE17 units. They engineer and manufacture robust standard and heavy-duty WE17 gearboxes, utilizing premium materials and advanced processes for demanding industrial applications. LYRADRIVE offers technical expertise for selection and provides customization support, making them a trusted partner for reliable power transmission solutions worldwide.