Worm Gear Drive WE14 Application in Heavy Industries

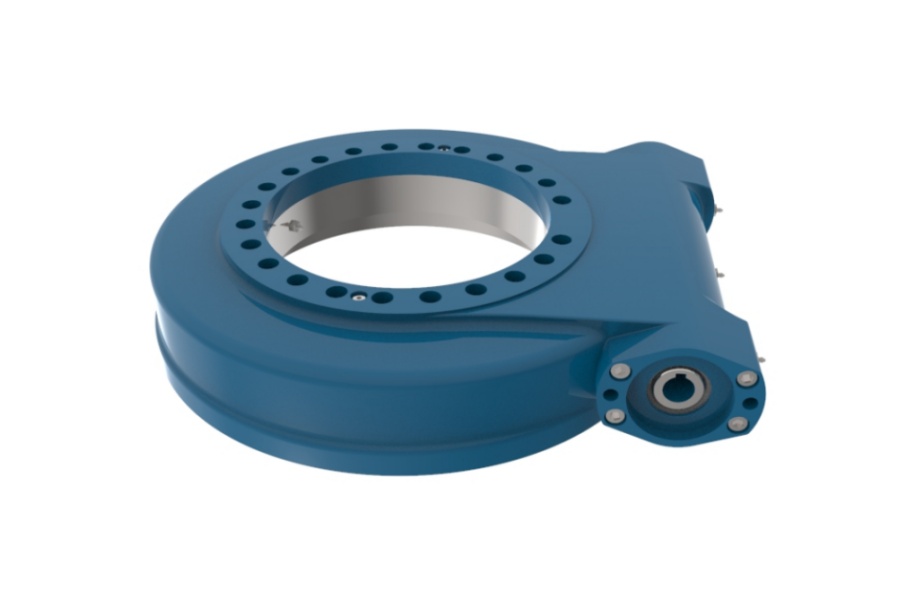

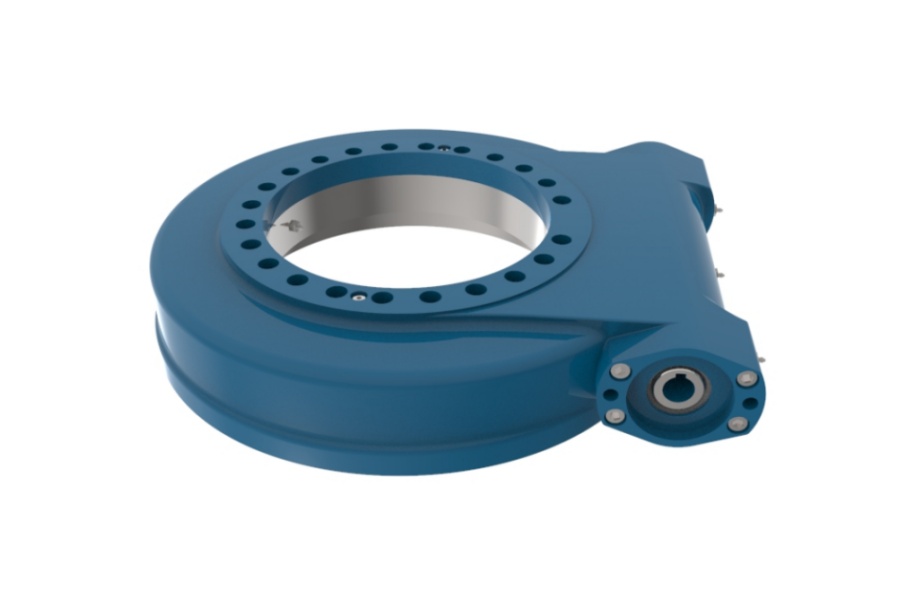

What is Worm Gear Drive WE14

Worm gear Drive WE14 is a compact right-angle drive system comprising a hardened steel worm (screw) that engages with a bronze alloy worm wheel. Engineered for high torque at low speeds, it offers inherent self-locking to prevent back-driving, making it ideal for vertical conveyors, hoists, and safety-critical systems.

Heavy Duty Worm Gearbox WE14

Heavy duty worm gearbox WE14 features reinforced bearings, high-strength alloy casings with cooling fins, and triple-labyrinth seals to withstand dust, moisture, and extreme temperatures. Its rigid construction absorbs high shock loads—up to 500% of rated torque—ensuring reliability in crushers, mills, and continuous mining operations.

Mining Crusher Gearbox Selection

Selecting gearboxes for mining crushers requires analyzing ore hardness (Mohs scale), crushing ratios (e.g., 6:1 for jaw crushers), and startup torque (300–400% of running torque). WE14 gearboxes excel in gyratory and cone crushers handling abrasive granite/basalt, with torque ratings from 18,500 Nm to 120,000 Nm. Key considerations include vibration resistance, IP66/IP69K sealing, and >100,000-hour design life under 24/7 operation.

Worm Gear Drive WE14 Characteristics

High Reduction Ratios: 10:1 to 100:1 in a single stage

Self-Locking: Prevents reverse rotation without brakes

Shock Load Tolerance: 500% momentary overload capacity

Efficiency: 85–92% with precision-ground helical worms

Noise Levels: <75 dB(A) at 1m distance

Maintenance Intervals: 20,000+ hours with synthetic lubricants

Worm Gear Drive WE14 Applications

Mining: Primary crushers, apron feeders, stacker-reclaimers

Cement: Raw mill drives, kiln feed systems, clinker coolers

Aggregates: Cone crushers, vibrating screens, washing plants

Material Handling: Ship loaders (up to 5,000 TPH), bucket elevators

Energy: Coal pulverizers, FGD slurry agitators

Steel: Continuous casters, slag conveyors

Worm Gear Drive WE14 Price Determinants

Factor | Impact on Cost |

Torque Rating | 18,500 Nm units cost 40% less than 120,000 Nm |

Materials | Nitrided steel worms + phosphor bronze wheels add 15–25% |

Sealing | Triple-lip seals + purge ports increase cost by 10% |

Accessories | Oil coolers/heaters add $1,200–$4,500 |

Certifications | ATEX/ISO 9001 compliance raises price 8–12% |

Order Volume | Batch orders of 50+ units reduce cost by 18% |

Worm Gear Drive WE14 Supplier

LYRADRIVE manufactures WE14 worm gearboxes to ISO 9001/AGMA 6024 standards. Their modular design allows custom shaft configurations (hollow, flanged, keyed), 22:1 to 80:1 ratio options, and 3,000+ ready-to-ship variants. LYRADRIVE provides lifetime technical support, predictive maintenance tools, and warranties—delivering mean time between failures (MTBF) exceeding 8 years in mining applications.