Worm Gear Drive WE14 Technical Specifications and Industrial Applications

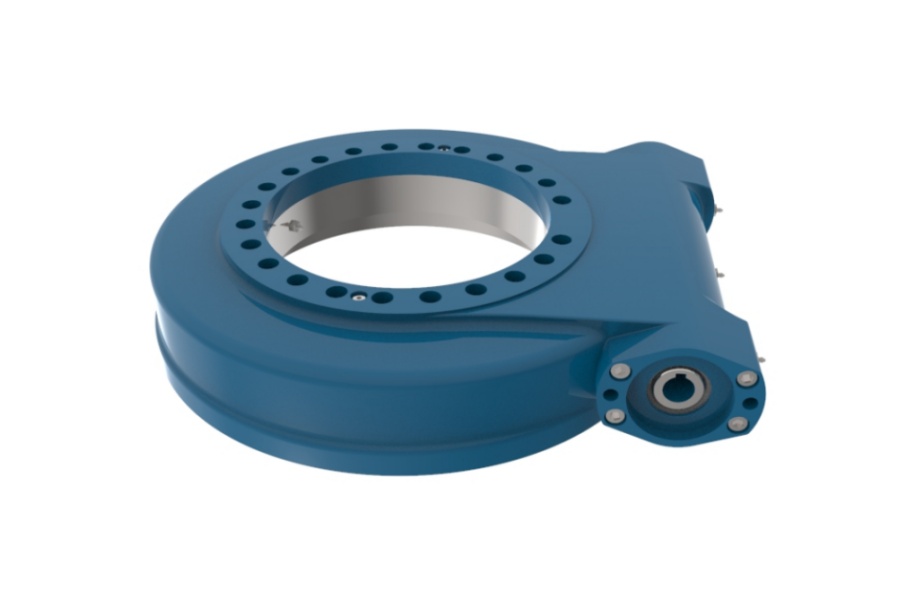

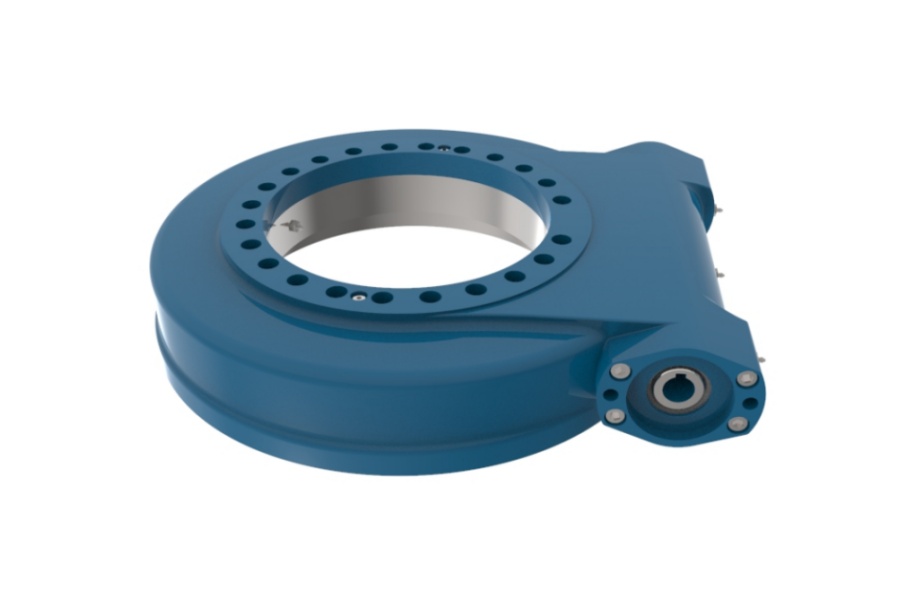

What is Worm Gear Drive WE14?

Worm Gear Drive WE14 is a specific size designation within a standardized series of worm gear reducers. It features a worm screw (typically hardened steel) meshing with a worm wheel (often bronze or phosphor bronze) housed within a durable cast iron or aluminum alloy casing. This configuration creates a right-angle drive, efficiently transmitting motion between perpendicular shafts. The "WE14" designation typically refers to a specific center distance (around 140mm is common, though exact dimensions vary by manufacturer) between the input and output shafts, defining its physical size and power capacity envelope. This size is particularly favored for applications needing substantial torque multiplication in a relatively compact footprint. The fundamental principle involves the worm screw's threads engaging the teeth of the worm wheel, resulting in a high reduction ratio achieved in a single stage, often offering self-locking capability when the lead angle is sufficiently small, preventing back-driving.

WE14 in Mining Crusher Applications

The mining industry subjects equipment to some of the harshest operating conditions imaginable, involving massive loads, constant shock, abrasive dust, and minimal maintenance windows. Worm Gear Drive WE14 finds critical application in various mining crusher mechanisms, particularly in secondary and tertiary crushing stages, as well as in feeder systems. Its inherent strengths make it well-suited for this brutal environment. The high torque output capacity of the WE14 size is essential for driving the crushing mechanisms that pulverize rock and ore. Its ability to handle substantial shock loads, generated when hard materials are fed into the crusher chamber, is crucial for longevity. Furthermore, the compact right-angle design simplifies integration into the often space-constrained crusher housings. Crucially, the self-locking characteristic inherent in many worm gear designs prevents the crushing mechanism from reversing due to the immense load when the drive motor is stopped, enhancing operational safety. While requiring robust sealing to combat pervasive dust and moisture, the WE14's design, when properly specified with hardened components and appropriate lubrication, provides the necessary durability for continuous, high-stress crushing operations, ensuring reliable throughput in mineral processing plants.

WE14 Output Torque Range

The output torque range of a Worm Gear Drive WE14 is a critical performance parameter, directly influencing its suitability for various applications. This range is not a single fixed value but depends heavily on several factors: the specific manufacturer's design and material choices, the chosen reduction ratio, the input speed (RPM), and the required service factor (accounting for load type and operating hours). Generally, WE14 gearboxes are designed for substantial torque transmission. Typical nominal output torque values for WE14 reducers can range from approximately 1,500 Nm (Newton-meters) up to 15,000 Nm or even higher for heavy-duty industrial models. Lower reduction ratios within the WE14 size will typically yield lower maximum output torque figures compared to higher reduction ratios offered in the same housing size. It is absolutely essential to consult the manufacturer's detailed technical catalog or datasheet for the exact WE14 model under consideration. These documents provide precise torque ratings (often categorized by input speed and reduction ratio), thermal capacity limits, and the necessary service factors based on the application's duty cycle (continuous, intermittent, shock loading). Selecting a WE14 unit with a torque rating that exceeds the application's peak requirement, incorporating an appropriate service factor, is fundamental to ensuring long service life and reliable operation.

Worm Gear Drive WE14 Characteristics

Worm Gear Drive WE14 offers a distinct set of characteristics that define its performance and application suitability. Its most notable feature is the ability to achieve high single-stage reduction ratios, often ranging from 5:1 up to 100:1 or more, within a very compact and space-efficient right-angle design. This makes it ideal where space is limited and significant speed reduction is needed. A significant advantage in many applications is its inherent self-locking capability, particularly at higher reduction ratios. This prevents the output shaft from driving the input shaft, a critical safety feature for hoists, conveyors, and crushers. While offering high reduction, worm drives generally exhibit good shock load absorption due to the sliding contact nature of the gear mesh. WE14 gearboxes are known for providing smooth and quiet operation, especially when precision-manufactured and adequately lubricated. However, it's important to note that worm gears typically have lower mechanical efficiency (often between 50% and 90%) compared to helical or planetary gearboxes, primarily due to the significant sliding friction between the worm and wheel. This sliding action also generates more heat, necessitating careful thermal management through proper lubrication, housing design, and potentially cooling fins or fans, especially in continuous duty or high-power applications. Despite the efficiency trade-off, the combination of high reduction in a compact package, self-locking, and robustness makes the WE14 a compelling choice for numerous demanding industrial scenarios.

Worm Gear Drive WE14 Applications

Leveraging its unique characteristics, Worm Gear Drive WE14 finds extensive use across a diverse spectrum of industries demanding robust power transmission in a compact form. Beyond its critical role in mining crushers and feeders, it is ubiquitous in material handling systems such as belt conveyors, bucket elevators, and screw conveyors, where its torque capacity and self-locking are invaluable. The construction sector relies on WE14 gearboxes for concrete mixers, crane slewing drives, and hoists, benefiting from their high starting torque and ability to hold loads securely. Industrial machinery utilizes them extensively in mixers, agitators, rotary kilns, and packaging equipment. Automation applications include positioning stages, rotary tables, and indexing mechanisms requiring precise angular control. They are vital components in food processing equipment like dough mixers and filling machines (using food-grade lubricants), wastewater treatment plants for driving screens and aerators, and agricultural machinery such as grain augers and feed mixers. The WE14's compact right-angle design is particularly advantageous in ventilation systems for large fans and gate/valve operators where space constraints exist. Essentially, wherever significant speed reduction, high torque output, shock resistance, and a space-saving right-angle configuration are required, the WE14 worm gearbox is a strong contender, particularly suited for moderate to high torque applications in the industrial power range it covers.

Factors Influencing Worm Gear Drive WE14 Price

The price of a Worm Gear Drive WE14 is not a fixed figure but varies considerably based on a multitude of design, manufacturing, and market factors. Material selection is paramount: high-strength alloy steel for the worm shaft, high-quality bronze alloys (like centrifugal cast phosphor bronze) for the worm wheel, and robust cast iron or aluminum for the housing directly impact cost, performance, and longevity. The reduction ratio offered can influence complexity and material volume within the same housing size. Manufacturing precision is critical; gearboxes with tighter tolerances, superior surface finishes, and optimized tooth profiles for efficiency and noise reduction command higher prices due to more advanced machining and quality control processes. Efficiency class is a major differentiator; units engineered for higher mechanical efficiency often involve more sophisticated designs and premium materials, increasing cost. The type and quality of bearings (e.g., tapered roller vs. ball bearings) and sealing systems (single lip seals, labyrinth seals, or specialized shaft seals for harsh environments) significantly affect reliability and price. Input configuration options (e.g., IEC standard motor flange, solid input shaft, hollow shaft with key or locknut) and output configurations (solid shaft, hollow shaft, various flange types) add complexity. Thermal management features like large finned surfaces or integrated cooling fans add cost. Brand reputation, certifications (ISO, ATEX for explosive atmospheres), service factors applied in the design, and the overall level of quality control and testing (e.g., full load testing) contribute to the price premium. Finally, order volume, customization requirements, and market demand/supply dynamics also play significant roles in the final cost of a WE14 worm gearbox.

Worm Gear Drive WE14 Supplier

LYRADRIVE is a prominent global manufacturer and supplier specializing in engineered power transmission solutions, including a comprehensive range of worm gearboxes like the WE14 model. They focus on robust design, quality manufacturing using durable materials, and offer various configurations and customization options for demanding industrial applications. LYRADRIVE provides essential technical support, detailed documentation, and responsive service, positioning itself as a trusted partner for integrating reliable WE14 drives into critical machinery worldwide.