What is Double Worm Slew Drive?

In the world of heavy-duty motion control, where high torque, precision, and unwavering reliability are non-negotiable, the double worm slew drive stands out as a premier engineering solution. This guide will explain what it is, how it works, and why it might be the perfect component for your most demanding applications.

What is Double Worm Slew Drive?

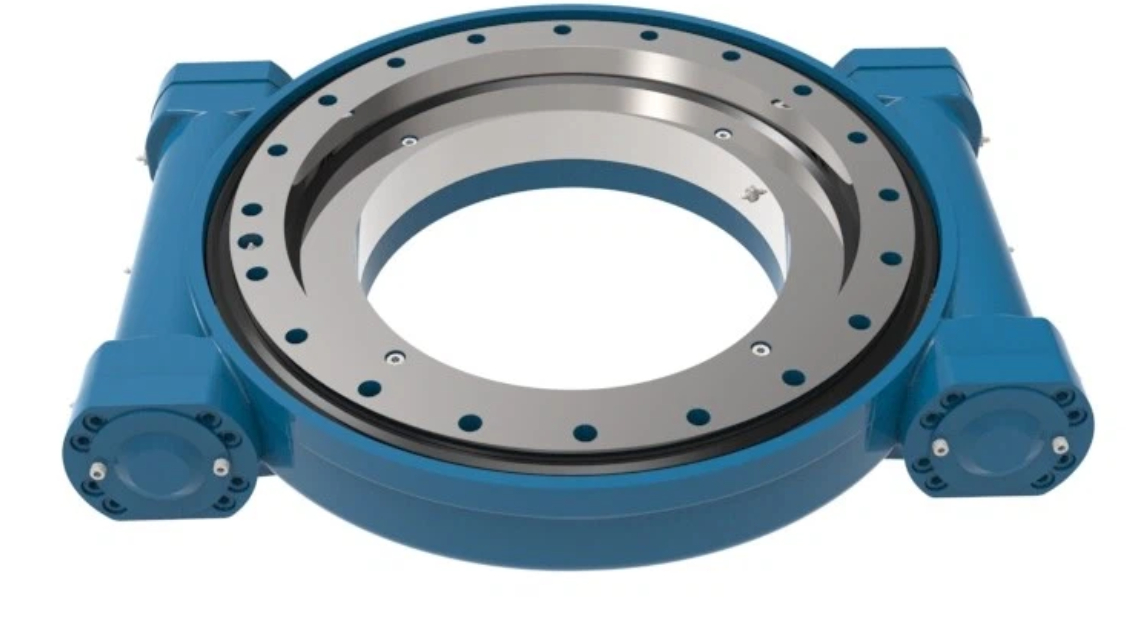

A double worm slew drive is a compact, integrated gearbox that provides high-torque, slow-rotation output on a horizontal axis. Its defining feature is the use of two independent worm gears (or input shafts) meshing with a single large worm wheel (slewing ring gear). This dual-input design is key to its superior performance, offering exceptional load capacity and rigidity in a single, self-contained unit. It combines the functions of a gear reducer, a 360-degree rotational bearing, and often a mounting structure into one robust package.

How Does Double Worm Slew Drive Work?

The principle is elegantly powerful:

Input: Two electric, hydraulic, or pneumatic motors (or hand cranks) drive the two separate worm screws.

Engagement: Both worms are precisely positioned 180 degrees apart on the circumference of the central worm wheel (the internal gear of the bearing).

Force Distribution: As the worms rotate, they engage with the teeth of the worm wheel simultaneously from opposite sides. This symmetrically distributes the driving force and load across the wheel.

Output: The rotational force from the two worms is transferred to the worm wheel, causing either the outer ring or the inner structure (depending on the design) to rotate smoothly and powerfully. The system is inherently self-locking, meaning the drive holds its position securely when the input stops, preventing back-driving.

Key Features and Advantages

The double worm slew drive offers distinct advantages over its single worm counterpart, making it the preferred choice for highly demanding applications. Its design unlocks capabilities that extend beyond simple rotation:

Unmatched Rigidity and Load Distribution: Unlike a single worm drive, the dual-worm design applies force symmetrically from two opposing points on the gear. This fundamental difference doubles the load-bearing contact area and dramatically increases torsional stiffness. It effectively minimizes gear deflection under heavy combined loads (axial, radial, and moment), ensuring precision and stability that a single worm cannot achieve.

Inherent System Redundancy and Safety: A key unique advantage is the built-in redundancy. In the event of a single worm or motor failure, the second worm can often maintain controlled operation or a safe, locked position. This fail-safe capability is critical in applications like heavy lifting, defense, or satellite tracking, where unexpected motion can lead to catastrophic outcomes.

Superior Anti-Backlash Performance: The two worms can be precisely adjusted to pre-load the gear system against each other. This unique setup actively eliminates backlash (free play between gear teeth) without relying solely on manufacturing tolerance. The result is exceptionally smooth, precise, and responsive motion control with zero starting lag, which is superior to the performance of most single-worm designs.

Balanced Wear and Extended Service Life: The symmetrical force distribution ensures that load and wear are spread evenly across the gear teeth. This prevents the localized wear patterns common in single-worm drives, where one side of the gear experiences more stress. Consequently, double worm drives typically exhibit longer operational life and more consistent performance over time, even under continuous heavy-duty cycles.

Higher Torque Capacity in a Comparable Footprint: By utilizing two input points, the double worm slew drive can transmit significantly higher torque than a single worm drive of a similar physical size. This allows engineers to achieve greater power density and meet high torque requirements without drastically increasing the drive's envelope, optimizing space in compact machinery designs.

Foundation for Simultaneous Two-Axis Movement: This is a truly distinctive capability. While a single double worm unit provides rotation around one axis, its robust, balanced, and compact design makes it the ideal and reliable core component for building dual-axis tracking or positioning systems. Two such drives can be orthogonally integrated to create a system capable of simultaneous and independent movement in both azimuth and elevation. This is essential for complex applications like advanced solar trackers, radar domes, and satellite communication antennas that must follow moving targets across the sky with high precision.

Key Comparisons: Double Worm vs. Single Worm Slew Drives

| Feature | Double Worm Slew Drive | Single Worm Slew Drive |

|---|---|---|

| Load Capacity & Stiffness | Very High. Ideal for heavy loads and high moment forces. | Standard. Suitable for moderate loads. |

| Redundancy | Yes. Offers a basic fail-safe feature. | No. Single point of failure. |

| Precision & Backlash | Minimal. Dual meshing pre-loads the system. | Can have slight backlash; may require adjustment. |

| Complexity & Cost | Higher due to two input assemblies and precise alignment needs. | Lower, simpler design. |

| Best For | Cranes, heavy-duty solar trackers, missile launchers, satellite antennas, mining equipment. | Lighter solar trackers, irrigation systems, light-duty positioning platforms. |

Applications of Double Worm Slew Drives

These drives are the workhorses of industries where failure is not an option:

Renewable Energy: Driving heavy solar trackers (especially in 1P or 2P configurations with large panel arrays) to withstand wind and snow loads.

Heavy Machinery: In crane booms, excavator turntables, and mining equipment for robust 360-degree rotation.

Defense & Aerospace: Positioning radar systems, satellite communication antennas, and weapon systems requiring pinpoint accuracy and reliability.

Industrial Automation: In heavy-duty indexing tables, welding positioners, and robotic rotary bases.

Installation, Calibration, and Maintenance Best Practices

Installation: Ensure the mounting surface is flat, rigid, and properly aligned to prevent induced stresses. Follow the manufacturer's torque specifications for mounting bolts precisely.

Calibration: Initial pre-load adjustment of the worm gears is crucial for optimal performance and longevity. This ensures proper meshing without excessive friction.

Maintenance: Adhere strictly to the lubrication schedule with the recommended grease. Regularly check seals for damage, inspect for unusual wear or noise, and re-tighten mounting bolts after the initial run-in period.

Professional Slew Drive Manufacturer

Choosing the right manufacturer is as critical as selecting the drive itself. A professional manufacturer doesn't just sell a product; they provide an engineered solution. For over 15 years, LyraDrive has been at the forefront of slew drive innovation, specializing in the design and production of high-performance single worm drives , double worm drives and spur gear slew drives for the most demanding applications worldwide.

Why Partner with LyraDrive?

Custom Engineering Excellence: Our engineering team doesn't just offer standard parts. We work directly with you to adapt and optimize designs for your specific load, speed, environmental, and integration requirements. Whether you need a modified flange, special sealing for extreme conditions, or a completely custom footprint, we deliver solutions, not just components.

Rigorous Quality Control: At LyraDrive, quality is engineered into every stage. We employ precision gear grinding, advanced heat treatment processes, and 100% functional testing to ensure every double worm drive meets the highest standards for durability, precision, and reliability. Our commitment to traceability and certification gives you complete confidence.

Proven Industry Expertise: With a proven track record across solar tracking, heavy machinery, aerospace, and defense, our drives are trusted where failure is not an option. We understand the unique challenges of each sector and engineer our products to exceed them.

Comprehensive Lifecycle Support: Our partnership extends beyond delivery. From initial design consultation and load analysis to after-sales support, maintenance guidance, and global technical service, the LyraDrive team is your dedicated engineering partner for the entire lifecycle of your project.

Conclusion

The double worm slew drive is a masterclass in mechanical design, offering unparalleled strength, reliability, and precision for the world's toughest rotational challenges. By understanding its advantages and partnering with a seasoned, innovative manufacturer like LyraDrive, you gain more than a component—you secure a reliable, high-performance solution backed by deep engineering expertise.

Looking for a robust, customized drive solution for your next project? Contact the LyraDrive engineering team today for a consultation.