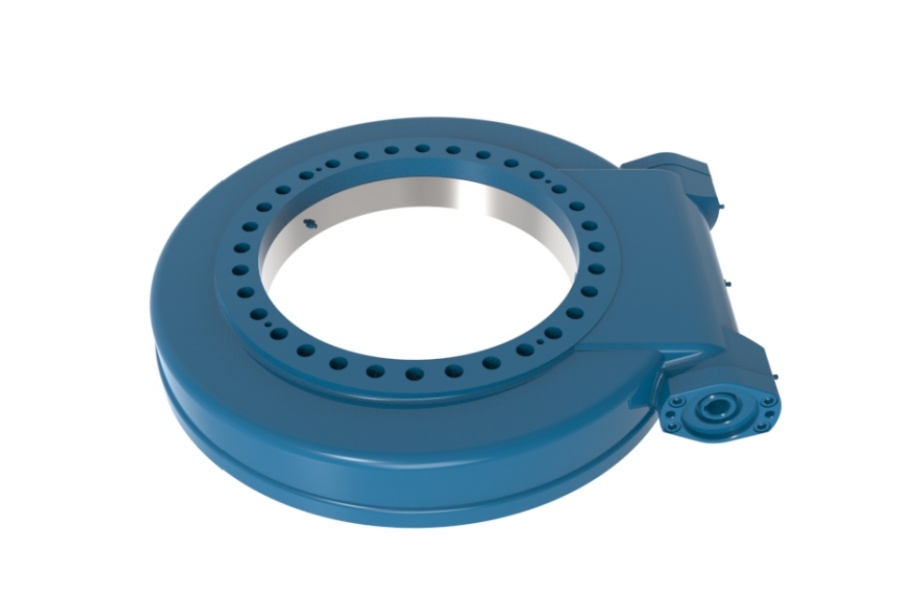

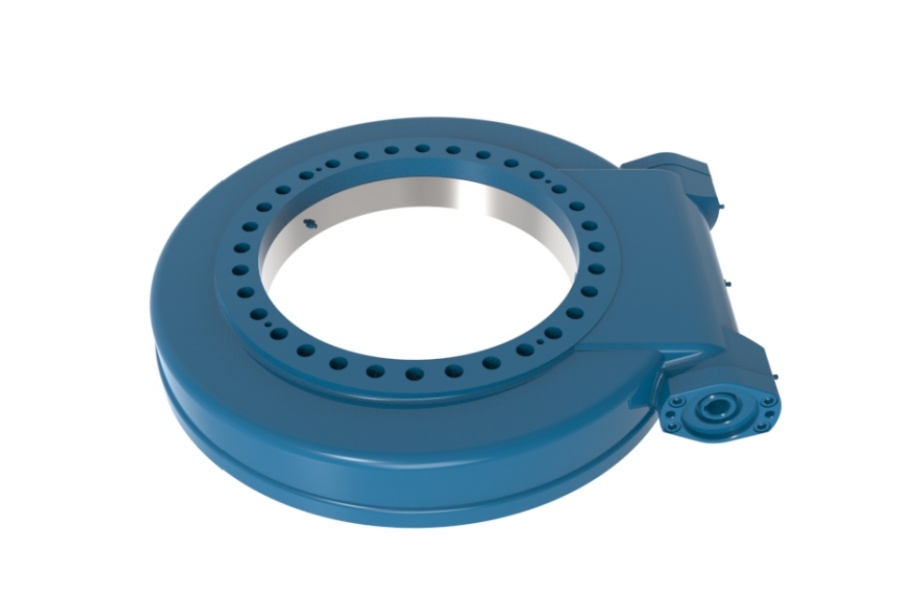

WE19 Worm Gear Drive Industrial Power Transmission Solution

What is Worm Gear Drive WE19?

Worm gear drive WE19 is a mechanical system where a threaded worm engages a bronze worm wheel. The "WE19" denotes a standardized 190mm center distance between shafts. This configuration provides substantial torque multiplication and speed reduction through sliding contact, with the worm driving the wheel at perpendicular axes.

Heavy-Duty Worm Gearbox WE19

WE19 units handle extreme industrial demands. Key features include:

Robust cast iron housings (GG25/GGG40) for vibration damping

Hardened alloy steel worms (16MnCr5/20MnCr5) paired with centrifugally cast phosphor bronze wheels (CuSn12)

Advanced sealing systems (lip/labyrinth/mechanical seals)

High-capacity tapered roller bearings

Reinforced output shafts with heavy-duty keyways/splines

WE19 Dynamic Load Calculation

Critical factors for reliable operation:

Nominal Output Torque (M₂) - Baseline operational torque

Service Factor (fB) - Adjusts for load severity (1.0-2.5+), considering:

Prime mover type (electric motor/IC engine)

Driven machine shock level (uniform/heavy shock)

Daily operating hours and start/stop frequency

Design Torque (M₂' = M₂ × fB) - Dynamic load capacity requirement

Efficiency (η) - Accounts for 40-90% energy loss from sliding friction

Thermal Validation - Heat dissipation capacity must exceed power loss [Input Power × (1-η)]

Characteristics of Worm Gear Drive WE19

High reduction ratios (5:1 to 100:1) in single-stage

Right-angle power transmission

Self-locking capability (prevents back-driving)

Compact high-torque design

Smooth low-speed operation

Axial thrust loads requiring specialized bearings

Bronze wheel sacrifice design for easier maintenance

Applications of Worm Gear Drive WE19

Material handling: Inclined conveyors, crane hoists, bucket elevators

Construction: Concrete mixers, winches, vibratory compactors

Processing: Food agitators, packaging conveyors, wastewater aerators

Industrial: Rotary indexes, rolling mills, dam gate actuators

Safety systems: Service elevators, positioning brakes

Factors Influencing WE19 Pricing

Material quality: Centrifugal-cast bronze vs. standard alloys

Manufacturing precision: AGMA/DIN gear class tolerances

Efficiency enhancements: Optimized tooth profiles/surface finishes

Thermal management: Cooling fins/fans/coil provisions

Configuration: Shaft-mounted vs. flange-mounted designs

Customization: Non-standard ratios, seals (Viton/double), hollow shafts

Certifications: ISO 9001/compliance testing

Order volume: Bulk production discounts

WE19 Worm Gear Drive Supplier

LYRADRIVE manufactures industrial-grade WE19 worm gear drives featuring hardened steel worms and bronze worm wheels. Their product range includes shaft-mounted and flange-mounted configurations with multiple ratio options. Units comply with international quality standards and support customization for specialized mounting, sealing, or shaft requirements. Technical documentation and integration guidance are provided for industrial applications.