Unlock Precision Motion: The Ultimate Guide to Medium Duty Slewing Drives

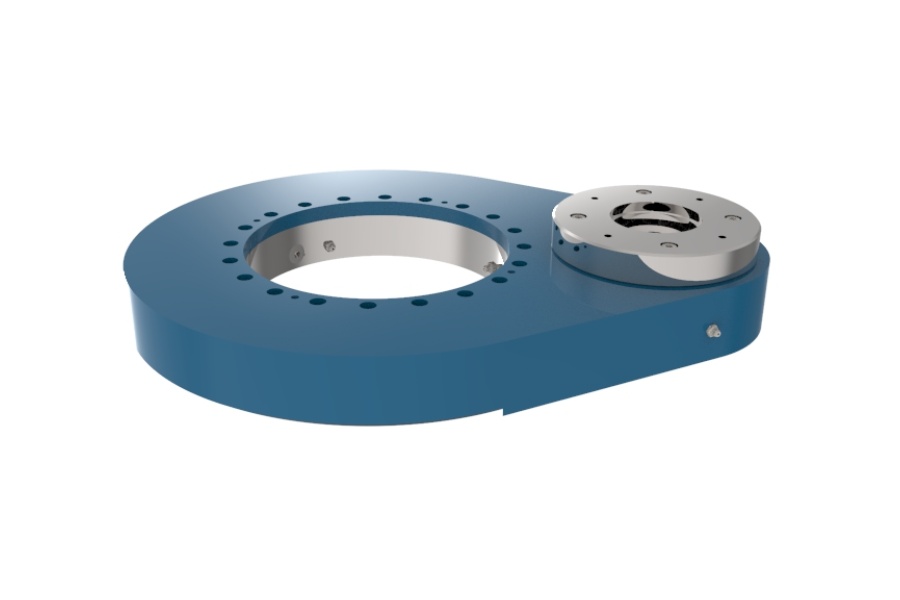

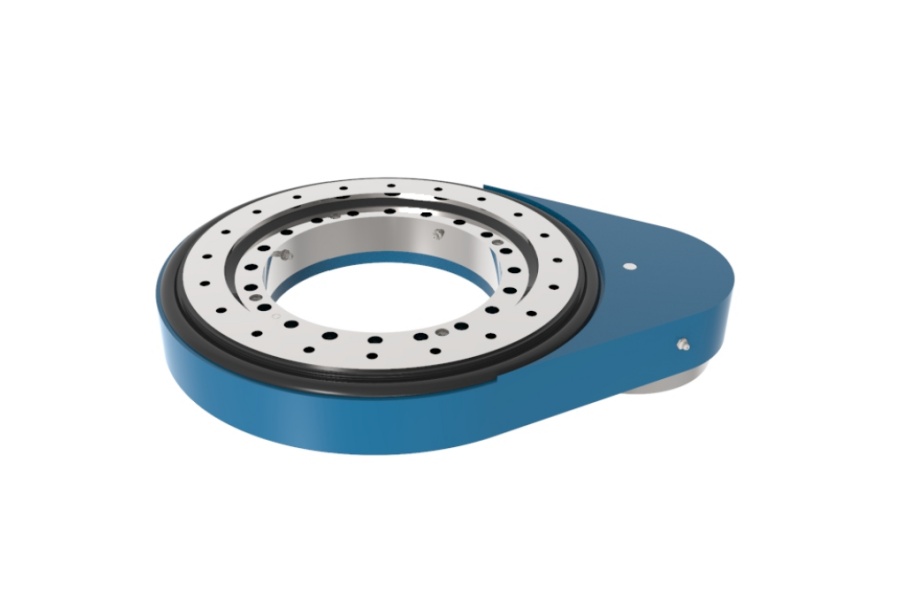

What is the Medium Duty Gear Slewing Drive SP-M 0311?

The SP-M 0311 is a meticulously engineered electromechanical system integrating a high-capacity slewing bearing with a compact, high-efficiency worm gear reduction unit into a single, robust housing. Designed for applications requiring significant torque output (up to 11 kNm), precise positioning, and reliable 360-degree continuous rotation under medium loads, it transforms input power (typically electric motor) into controlled, high-torque rotational output. Key identifiers include its compact yet powerful design, optimized gear geometry for smooth operation and high efficiency, robust sealing for harsh environments, and versatile mounting options. It represents the ideal blend of strength, precision, and durability for a wide array of demanding tasks.

Understanding Medium Duty Slewing Drives

Medium duty slewing drives occupy a critical niche between lighter-duty units used for smaller applications and heavy-duty behemoths designed for massive loads like cranes or excavators. They are characterized by their ability to handle substantial torque (typically ranging from several hundred Nm up to around 20-30 kNm) and moderate axial, radial, and moment loads simultaneously. The core principle involves a worm gear meshing with an internal gear ring integrated into the slewing bearing's outer or inner race. This configuration provides inherent self-locking capability (preventing back-driving under load when the worm isn't powered), high reduction ratios for torque multiplication, and smooth, controllable motion. Medium duty drives excel where reliability, precision, space efficiency, and resistance to environmental factors like dust, moisture, or temperature variations are paramount, making them indispensable across solar energy, antenna positioning, material handling, automation, and various industrial machinery sectors.

The Critical Role in Antenna Positioning Systems

Precision and unwavering reliability are non-negotiable in antenna positioning systems, whether for satellite communication (SATCOM), radar, radio astronomy, or telemetry. Slewing drives like the SP-M 0311 are the workhorses powering the azimuth (horizontal) and often elevation (vertical) axes of these critical systems. Their function goes beyond mere rotation; they must provide:

Extreme Accuracy: Sub-degree positioning repeatability to ensure the antenna beam is precisely pointed at its target satellite or location.

Smooth Motion: Vibration-free operation is essential to prevent signal degradation or loss.

High Stiffness: Minimal deflection under operational wind loads or antenna inertia to maintain pointing accuracy.

Robustness: Operation in diverse, often harsh environments – from scorching deserts to freezing mountaintops, exposed to UV, rain, snow, and salt spray.

Backlash Control: Minimal mechanical play (backlash) is critical to prevent positioning errors and oscillation.

Self-Locking Security: Preventing unintended movement due to wind gusts or gravitational forces when the drive is stationary.

The SP-M 0311, with its precision gearing, robust construction, and proven environmental sealing, is engineered to meet these stringent demands, ensuring uninterrupted communication and data acquisition.

Powering Efficiency in Solar Tracker Systems

Maximizing energy harvest in photovoltaic (PV) power plants hinges on the precise alignment of solar panels with the sun throughout the day. Slewing drives are the fundamental actuators enabling single-axis (horizontal tracking - azimuth) and dual-axis (azimuth + elevation) solar trackers. The SP-M 0311 is ideally suited for medium-sized tracker rows or sections, offering:

High Torque Density: Delivers the necessary torque to rotate multiple panels reliably, even under significant wind loading, within a compact footprint.

Precision Positioning: Ensures panels follow the calculated sun path accurately, maximizing energy capture.

Durability & Low Maintenance: Built to withstand decades of continuous daily movement, temperature extremes (-30°C to +80°C+), dust, and moisture, minimizing operational downtime and lifecycle costs.

Efficiency: Optimized gear design reduces power consumption from the tracker's motor, improving overall system efficiency.

Cost-Effectiveness: Provides the essential robustness and performance required for utility-scale and commercial solar projects at a competitive total cost of ownership. The reliability of the slewing drive directly impacts the power plant's uptime and revenue generation.

Distinctive Features of the SP-M 0311

The Medium Duty Gear Slewing Drive SP-M 0311 distinguishes itself through a combination of advanced engineering and robust design:

High Torque Output: Engineered to deliver up to 11 kNm of output torque, handling significant rotational loads.

Precision Worm Gear Design: Features optimized gear geometry and high-quality materials (e.g., hardened steel worm, bronze gear wheel) for smooth operation, high efficiency, minimal backlash, and extended service life.

Integrated Slewing Bearing: Incorporates a durable, single-row ball or cross-roller slewing bearing capable of handling combined axial, radial, and moment loads efficiently.

Robust Housing: Manufactured from high-strength materials (often ductile iron or steel), providing structural integrity and protection for internal components.

Advanced Sealing: Utilizes high-performance seals (often multi-labyrinth designs with grease purges) to effectively exclude contaminants like dust and water and retain lubricant, ensuring longevity in harsh outdoor environments.

Versatile Mounting: Offers multiple standardized flange and base mounting patterns (e.g., ISO or SAE), simplifying integration into diverse system designs.

Efficient Lubrication: Designed for long lubrication intervals with accessible grease fittings, reducing maintenance requirements.

Self-Locking Capability: The worm gear design provides inherent holding torque, preventing back-driving when power is off (critical for safety and positioning).

Compact Design: Achieves high power density, saving valuable space within the application.

Customization Options: Often available with various input shaft configurations (keyed, splined), mounting flanges, lubrication types, and optional features like encoders or brakes.

Diverse Applications Beyond Antennas and Solar

The versatility of the SP-M 0311 extends far beyond its core roles in antenna positioning and solar tracking:

Material Handling: Rotating platforms for palletizers, stackers, positioners, automated guided vehicles (AGVs), and conveyor turntables.

Industrial Automation: Indexing tables, welding positioners, robotic tool changers, and assembly line rotation stations requiring precise angular movement.

Packaging Machinery: Rotating capping heads, labeling stations, and product orientation units.

Medical Equipment: Positioning components in imaging devices (CT, X-ray) and specialized treatment tables.

Defense & Aerospace: Turret rotation for surveillance systems, actuator drives for ground support equipment.

Test & Simulation Equipment: Positioning heavy test articles or environmental chambers.

Recycling & Waste Handling: Rotating shredder feed hoppers, sorting arms, and baler feed mechanisms.

Stage & Entertainment: Controlling the movement of lighting rigs, camera platforms, and rotating stages.

Agricultural Machinery: Positioning sprayer booms or specialized harvesting equipment.

Wherever controlled, powerful, and reliable rotation is needed within the medium duty torque range, the SP-M 0311 offers a robust solution.

Factors Influencing SP-M 0311 Pricing

The cost of a Medium Duty Gear Slewing Drive SP-M 0311 is not a fixed figure but is influenced by several key variables:

Order Quantity: Significant volume discounts are typically available for larger purchases common in projects like solar farms.

Customization Level: Standard catalog units are most economical. Modifications like special input shafts (splines vs. keyway), unique mounting flanges, custom seals for extreme environments, integrated brakes, or added sensors (encoders, resolvers) increase cost.

Material Specifications: While standard materials are optimized, requests for specific high-grade alloys or special coatings (e.g., corrosion protection beyond standard) impact price.

Precision & Backlash Requirements: Tighter manufacturing tolerances and specialized assembly processes needed for ultra-low backlash versions command a premium.

Sealing & IP Rating: Standard sealing is robust, but achieving very high IP ratings (e.g., IP68 for submersion) requires advanced sealing solutions, increasing cost.

Lubrication Type: Standard grease is common, but specific requirements for synthetic grease or even oil lubrication systems add cost.

Supplier & Brand Reputation: Established manufacturers with proven quality, reliability, and global support networks often command prices reflecting that value.

Geographic Location & Logistics: Import duties, shipping costs, and local distribution markups affect the final landed price.

Market Conditions: Fluctuations in raw material costs (steel, copper) and manufacturing energy costs can influence pricing over time.

Technical Support & Warranty: Comprehensive warranties and readily available engineering support are value-added services factored into pricing.

Supplier of Medium Duty Gear Slewing Drive SP-M 0311

When sourcing the critical component that is the Medium Duty Gear Slewing Drive SP-M 0311, partnering with a reliable and experienced manufacturer is paramount. LYRADRIVE has established itself as a leading global supplier of high-performance slewing drives and slewing bearings. Choosing LYRADRIVE means investing in:

Engineering Excellence: Deep expertise in gear design, bearing technology, and tribology, resulting in optimized performance and durability.

Rigorous Manufacturing & Quality Control: State-of-the-art production facilities and stringent quality processes (ISO 9001 certified) ensure consistent product excellence and traceability.

Proven Reliability: Products designed and tested to perform reliably in the most demanding environments over extended operational lifetimes.

Global Support Network: Access to responsive technical support, sales expertise, and after-sales service across key regions.

Customization Capability: Extensive experience in adapting standard designs like the SP-M 0311 to meet specific application challenges and integration requirements.

Competitive Value: Delivering a superior balance of performance, durability, and total cost of ownership.

LYRADRIVE doesn't just supply components; they provide engineered motion solutions backed by deep application knowledge and a commitment to customer success. Their SP-M 0311 is a testament to this philosophy, offering a robust, precise, and reliable drive for mission-critical rotation across a vast spectrum of industries.

Conclusion: The Engine of Controlled Rotation

The Medium Duty Gear Slewing Drive SP-M 0311 exemplifies the sophisticated engineering required to deliver powerful, precise, and reliable rotational motion in demanding environments. Its integration of a robust slewing bearing with a highly efficient worm gear reduction creates a compact yet formidable actuator. From ensuring global communications via precise antenna pointing to maximizing renewable energy generation through accurate solar tracking, and powering countless industrial automation and material handling tasks, the SP-M 0311 is a fundamental enabler of modern technology. Understanding its features, capabilities, and the factors affecting its investment allows engineers and procurement specialists to make informed decisions. Partnering with a proven manufacturer like LYRADRIVE ensures access not only to a high-quality product but also to the engineering support and reliability essential for long-term operational success. When your application demands dependable medium-duty rotation, the SP-M 0311 stands ready as a cornerstone solution.