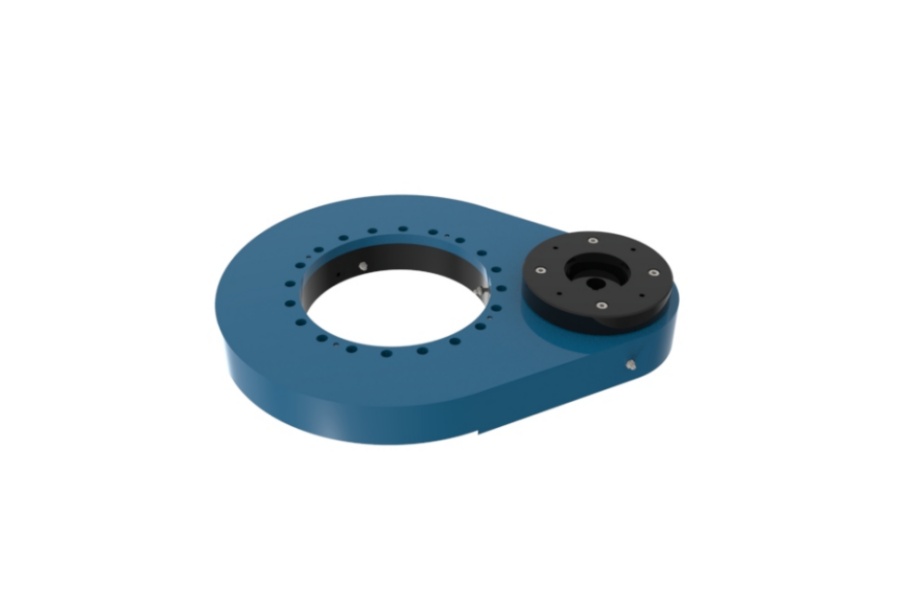

The SP-I 0311: Where Featherweight Agility Meets Essential Turntable Power

What is the Lightweight Slewing Ring Gear Drive SP-I 0311?

The Lightweight Slewing Ring Gear Drive SP-I 0311 represents a specialized category of motion control device. It integrates two critical components into a single, compact unit: a slewing ring bearing and a precision gear drive mechanism. Unlike bulky traditional slewing drives, the SP-I 0311 prioritizes minimal weight and space utilization without sacrificing core functionality. It's specifically designed for scenarios demanding smooth, controlled rotation at moderate speeds under relatively lighter axial, radial, and moment loads. Think of it as the essential "engine" for smaller turntables, positioning stages, and scanning platforms where conventional drives are simply overkill. Its design philosophy centers on providing just the right amount of power and support in the most efficient package possible, making sophisticated motion accessible and affordable.

The Foundation: Understanding Turntable Bearings

At the heart of any rotational system lies the turntable bearing, also known as a slewing ring bearing. This isn't your average ball or roller bearing; it's a large-diameter bearing explicitly designed to handle combined loads – forces acting simultaneously from different directions (axial loads pushing down, radial loads pushing sideways, and tilting moments trying to tip the platform). Slewing rings feature robust inner and outer rings with precisely engineered raceways accommodating rolling elements (balls or rollers). They provide the critical low-friction interface between a stationary base and a rotating platform, enabling smooth and stable rotation under load. The SP-I 0311 incorporates a lightweight, optimized slewing ring bearing as its core structural and rotational element, forming the foundation upon which the drive mechanism acts.

The Mechanism: Light-Duty Turntable Drive Systems

Light-duty turntable drive mechanisms are engineered for applications where the loads and duty cycles are less demanding than those encountered in heavy industrial machinery like cranes or excavators. They prioritize factors like compactness, low power consumption, quiet operation, ease of integration, and cost-effectiveness. These systems typically involve a compact electric motor (often a gearmotor) transmitting torque through a reduction gearbox. This gearbox then meshes with a gear tooth profile integrated onto either the inner or outer ring of the turntable bearing. The SP-I 0311 exemplifies this light-duty philosophy perfectly. Its integrated gear drive is optimized for efficient power transmission within its designated load capacity, focusing on smooth motion, precision positioning (where required), and reliable operation without the unnecessary bulk or expense of heavier-duty solutions.

The Advantage: Embracing Economical Slewing Drives

Economical slewing drives fill a crucial niche in the motion control landscape. They offer the fundamental benefits of integrated rotation and drive – simplified design, reduced assembly time, guaranteed component compatibility, and space savings – but at a significantly lower price point than their heavy-duty counterparts. This economy is achieved through intelligent design choices: utilizing lighter materials like optimized alloys or advanced engineering plastics where appropriate, simplifying gear profiles and reduction stages, focusing on core functionalities without excessive sealing or redundancy, and leveraging efficient manufacturing processes. The SP-I 0311 is a prime example of an economical slewing drive. It delivers the essential performance needed for countless light-duty applications without the premium associated with over-engineered solutions, making automation and precise motion accessible for a wider range of projects and budgets.

Unpacking the SP-I 0311: Key Features and Benefits

The Lightweight Slewing Ring Gear Drive SP-I 0311 stands out due to a suite of features meticulously designed for its target market:

Exceptional Weight Reduction: Engineered with advanced materials and structural optimization, the SP-I 0311 achieves weight savings often exceeding 30-40% compared to similarly sized conventional steel slewing drives. This drastically reduces the inertia of the moving platform and minimizes the load on supporting structures.

Compact Design: Its integrated nature and focus on minimalism result in a remarkably small footprint and low profile, freeing up valuable space within equipment designs and enabling use in constrained environments.

Integrated Efficiency: Combining the bearing and drive into one pre-assembled, pre-lubricated unit eliminates alignment hassles, reduces part count, simplifies installation, and ensures optimal meshing between the drive pinion and the slewing ring gear.

Smooth & Precise Operation: Precision manufacturing of the gear teeth and bearing raceways ensures low noise, minimal vibration, and smooth rotation, crucial for scanning, positioning, and user experience.

Cost-Effectiveness: The focus on lightweight materials (where suitable), design efficiency, and streamlined manufacturing directly translates into a highly competitive price point, offering excellent value.

Versatile Mounting: Designed for easy integration, typically offering standard bolt patterns on both the stationary and rotating rings for straightforward mounting to bases and platforms.

Optimized for Light Loads: Precisely engineered to handle moderate axial, radial, and moment loads typical of light-duty automation, medical equipment, solar trackers (smaller panels), display units, and similar applications.

Low Power Requirements: The reduced weight and optimized gearing mean smaller, more energy-efficient motors can be used, lowering overall system energy consumption and cost.

Where Lightweight Precision Shines: SP-I 0311 Applications

The unique blend of lightness, compactness, economy, and reliable rotational motion makes the SP-I 0311 ideal for a diverse array of applications:

Automated Guided Vehicles (AGVs): Rotating transfer decks, lifting platforms, and sensor turrets benefit immensely from the low weight and compact size.

Medical & Laboratory Equipment: Positioning stages for imaging devices, sample handling arms, and treatment tables where smooth, precise motion and cleanliness (ease of integration into enclosures) are key.

Robotics (Light Payload): Rotary joints for collaborative robots (cobots) or smaller robotic arms handling lightweight components.

Packaging & Material Handling: Indexing tables, sorting turntables, and light-duty conveyor diverters requiring reliable, compact rotation.

Renewable Energy: Small-scale solar tracker systems (single or dual-axis for residential/commercial panels), where minimizing weight on the support structure is critical for cost and wind resistance.

Display & Retail: Rotating product displays, interactive kiosks, and digital signage platforms needing smooth, quiet operation.

Test & Measurement Equipment: Positioning platforms for sensors, cameras, or devices under test requiring controlled rotation.

Recreational Equipment: Turntables for simulators (flight, driving), rotating stages for exhibits, or camera dollies.

Agricultural Automation: Lightweight sensor platforms or positioning mechanisms on smaller autonomous equipment.

Understanding the Price Drivers of the SP-I 0311

While inherently economical, the price of an SP-I 0311 slewing drive can be influenced by several factors:

Material Selection: The specific alloys or advanced polymers used significantly impact cost. High-strength, lightweight aerospace-grade aluminum or specialized engineering plastics command a premium over standard grades.

Precision & Tolerances: The required level of gear tooth accuracy, bearing raceway smoothness, and overall dimensional tolerances directly affect manufacturing complexity and cost. Tighter tolerances for high-precision applications increase price.

Gear Specifications: Module/pitch, pressure angle, tooth profile (straight vs. helical - though helical is less common in ultra-lightweight), and hardening/treatment processes influence manufacturing cost.

Bearing Internal Design: The type and size of rolling elements (balls vs. rollers), number of rows, and sealing solutions (standard seals vs. specialized low-friction or high-ingress protection) affect the cost.

Customization: While the SP-I 0311 is often an off-the-shelf item, any modifications – special bolt patterns, unique shaft outputs on the drive motor, custom sealing, specific pre-lubrication, or surface treatments (anodizing, coatings) – add cost.

Order Quantity: Bulk purchases typically benefit from volume discounts compared to single-unit orders.

Drive Motor Integration: Whether the unit is supplied as just the slewing drive mechanism or includes an integrated electric motor (and the specifications of that motor) is a major cost factor.

Supply Chain & Logistics: Raw material costs, manufacturing location, and shipping expenses can fluctuate and impact the final price.

Supplier Value-Add: Technical support, design assistance, comprehensive warranties, and reliable lead times contribute to the overall value proposition offered by the supplier.

Your Source for Precision Lightweight Motion: Partnering with the Right Supplier

Selecting a reliable supplier is paramount when sourcing critical components like the Lightweight Slewing Ring Gear Drive SP-I 03110You need a partner that offers not just the product, but the expertise and support to ensure successful integration. Look for suppliers with:

Proven Expertise: Deep understanding of slewing ring technology, gear drives, and lightweight design principles.

Manufacturing Control: Direct oversight or strong partnerships with manufacturing facilities ensuring consistent quality and adherence to specifications.

Technical Support: Ability to provide pre-sales engineering advice, assist with load calculations, and offer integration guidance.

Quality Assurance: Rigorous testing protocols (torque, backlash, runout, smoothness) and comprehensive quality certifications.

Reliability & Consistency: Proven track record of on-time delivery and consistent product performance.

Value-Added Services: Options for customization, kitting (motors, controllers), and responsive after-sales support.

Transparency: Clear communication regarding specifications, pricing, lead times, and any limitations.

Supplier of SP-I 0311

One company consistently at the forefront of developing and supplying advanced, lightweight motion solutions like the SP-I 0311 is LYRADRIVE. They have established themselves as a key player by focusing on the specific needs of light-duty and compact automation. LYRADRIVE's commitment to innovation is evident in their SP-I series, which pushes the boundaries of weight reduction and integration efficiency. Their engineers possess deep expertise in optimizing slewing ring and gear drive interactions for maximum performance in minimal packages. Beyond just manufacturing, LYRADRIVE provides significant value through application engineering support, helping customers select the right model and integrate it seamlessly into their designs. They understand the critical importance of reliability in light-duty applications and back their products with robust quality control processes. For OEMs and system integrators seeking a high-performance, lightweight slewing drive solution backed by technical know-how and reliable supply, LYRADRIVE stands as a trusted and capable partner, ready to empower your next innovative project with the agility of the SP-I 0311.