The Precision Powerhouse Revolutionizing Modern Machinery: Crossed Roller Slewing Bearings Explained

What Exactly Are Crossed Roller Slewing Bearings?

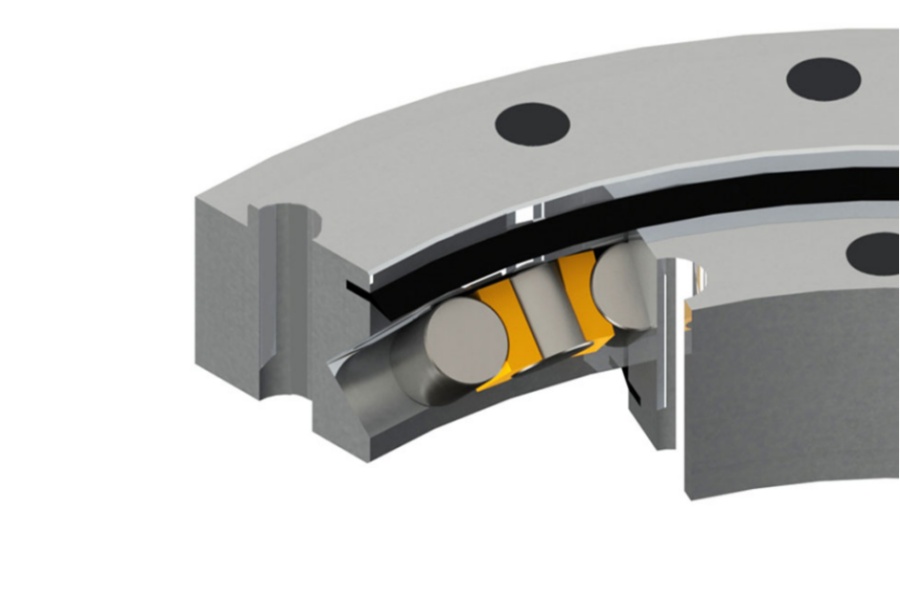

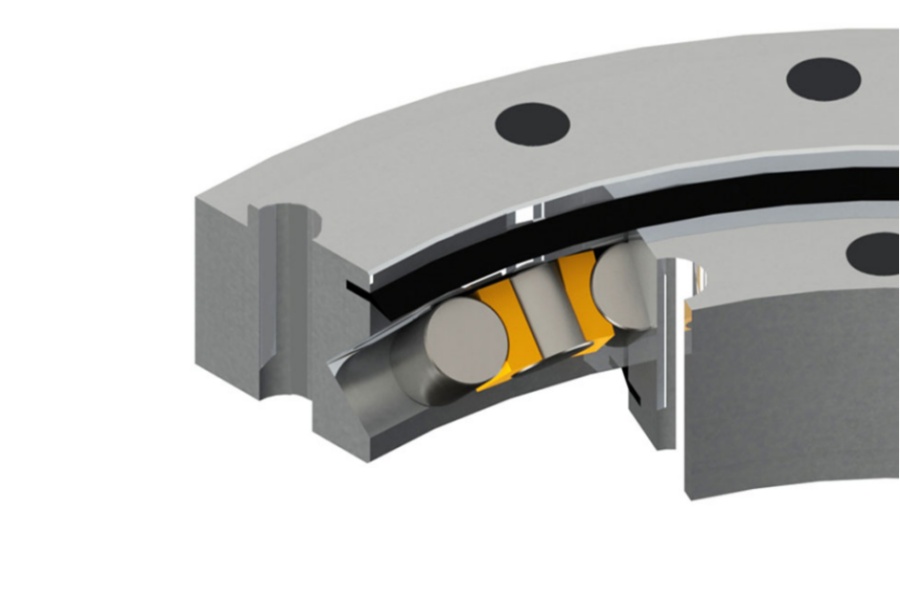

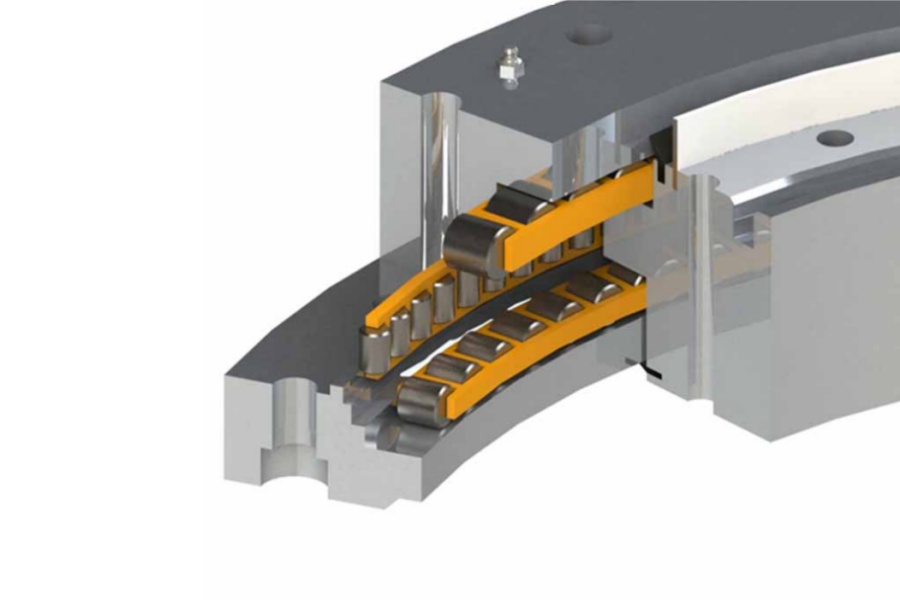

Forget bulky, complex bearing arrangements. Crossed roller slewing bearings (often abbreviated CRSBs or XRB slewing rings) represent a pinnacle of efficiency and precision in rotary motion. Their defining characteristic lies in the unique orientation of their rolling elements. Instead of balls or tapered rollers, they utilize cylindrical rollers meticulously arranged at right angles (90 degrees) to each other in alternating rows within a single, compact bearing assembly. These rollers run directly on precisely ground V-shaped or flat raceways integrated into the inner and outer rings. This ingenious crossed configuration allows a single bearing unit to simultaneously handle radial loads, axial (thrust) loads in both directions, and tilting moments with remarkable stability and minimal elastic deformation. Essentially, they consolidate the functions typically requiring multiple conventional bearings into one highly space-efficient package, making them indispensable for applications demanding extreme accuracy and stiffness.

Delving Deeper: The Cross Roller Pivot Bearing

A critical subset within the crossed roller family is the cross roller pivot bearing. These bearings are specifically engineered for applications requiring precise, limited angular rotation – often less than 360 degrees, sometimes just a few degrees – around a single axis. They excel in scenarios demanding very high rigidity and minimal deflection under significant moment loads. Think of robotic arm joints, precision indexing tables, or the articulation points in sophisticated machinery. Their compact design minimizes the pivot point's overall size while maximizing load-bearing capability and rotational accuracy. The crossed rollers ensure virtually no clearance and exceptional repeatability, crucial for maintaining precise positioning during pivotal movements. They are the go-to solution when space is constrained, but performance cannot be compromised on pivotal axes.

The Epitome of Alignment: Optical Alignment Bearings

Pushing precision to its absolute limit, optical alignment bearings represent the zenith of crossed roller bearing technology. These are specialized, ultra-high-precision crossed roller bearings designed explicitly for applications where nanometer-level stability and angular accuracy are non-negotiable. Found in the heart of semiconductor lithography equipment (like EUV scanners), advanced astronomical telescopes, sophisticated laser communication systems, and metrology instruments, these bearings are true marvels of engineering. Every aspect – from the micron-level tolerances of the raceways and rollers to the homogeneity of the bearing steel and the meticulous assembly process – is controlled to an extraordinary degree. They often incorporate unique features like integral mounting reference surfaces, specialized lubrication for minimal disturbance, and materials selected for extreme dimensional stability under thermal changes. Their primary function is to provide a perfectly stable, repeatable, and near-frictionless rotational platform for aligning optical components with unparalleled accuracy, where even the slightest vibration or angular error is catastrophic.

Unpacking the Key Characteristics of Crossed Roller Slewing Bearings

What makes CRSBs stand out in the crowded bearing marketplace? Their unique design delivers a compelling set of advantages:

Exceptional Rigidity & Low Elastic Deformation: The line contact of the rollers and the direct, rigid structure result in minimal deflection under load, crucial for maintaining precision positioning.

High Rotational Accuracy: Precision grinding of components and minimal rotational fluctuation ensure smooth, accurate motion vital for CNC equipment and measuring devices.

Compact & Space-Saving Design: Integrating multiple load capacities into one unit significantly reduces overall system footprint and weight.

High Load Capacity: Capable of handling substantial radial, axial (both directions), and moment loads simultaneously due to the optimized roller contact.

Smooth & Precise Motion: Low friction torque and minimal starting torque contribute to responsive control and fine positioning.

Simplified Design & Assembly: Replacing complex multi-bearing setups with a single unit simplifies machine design, assembly, and maintenance.

High Stiffness: Provides excellent resistance to deformation under load, maintaining system integrity.

Minimal Runout: Ensures the axis of rotation remains consistent, critical for accuracy.

Where Precision Meets Power: Diverse Applications of Crossed Roller Bearings

The unique blend of compactness, high load capacity, and exceptional accuracy makes CRSBs ubiquitous across cutting-edge industries:

Industrial Robotics: Robot arm joints (especially critical rotary axes), end-effector wrists, and precision positioning stages demand their rigidity and accuracy.

Machine Tool & CNC: Rotary tables, indexers, tool changers, and C-axis spindles rely on them for precise workpiece positioning and machining accuracy.

Semiconductor Manufacturing: Critical in wafer steppers, scanners (EUV), inspection equipment, and photolithography stages where nanometer precision is essential.

Medical Imaging & Equipment: CT scanners, MRI machines, radiation therapy devices (linac gantries), and surgical robots utilize them for smooth, precise, and reliable motion.

Optics & Photonics: Telescope mounts (especially altitude-azimuth designs), laser cutting heads, mirror positioning systems, and optical alignment stages depend on their stability.

Aerospace & Defense: Satellite antenna positioning systems, missile guidance gimbals, radar platforms, and flight simulators require their robustness and precision.

Automation & Material Handling: Precision rotary indexing tables, robotic palletizers, automated assembly stations, and coordinate measuring machines (CMMs).

Energy: Solar tracker systems for photovoltaic panels and components within wind turbine pitch/yaw control mechanisms.

Understanding the Investment: Factors Influencing Crossed Roller Slewing Bearing Price

The cost of a crossed roller bearing is not arbitrary; it's dictated by the precision engineering and materials involved. Key factors include:

Size & Dimensions: Larger bearings with greater diameters and widths inherently require more material and complex machining, increasing cost significantly.

Load Capacity & Rigidity Requirements: Bearings engineered to withstand higher radial, axial, and moment loads demand larger rollers, wider raceways, and potentially higher-grade materials, adding expense.

Precision Class & Tolerance: Standard tolerances are cost-effective. However, bearings manufactured to ABEC 7, ABEC 9, P4, P2, or specialized ultra-high-precision (e.g., optical grade) tolerances involve vastly more stringent manufacturing processes, inspection, and handling, dramatically increasing price.

Material Selection: Standard high-carbon chromium bearing steel (like SUJ2/52100) is common. However, bearings requiring corrosion resistance (stainless steel - e.g., AISI 440C), extreme cleanliness (vacuum re-melted steel), or specialized alloys for dimensional stability add cost.

Customization & Design Complexity: Standard catalog bearings are most economical. Modifications like custom flange configurations, special mounting holes, integral gears, unique sealing solutions, specific lubrication, or non-standard preload levels require engineering and unique production runs, increasing price.

Quantity: Unit cost typically decreases with larger order volumes due to economies of scale in production and setup amortization.

Brand Reputation & Quality Assurance: Reputable manufacturers investing heavily in R&D, state-of-the-art manufacturing, rigorous quality control (including 100% inspection for high-precision grades), and certifications (ISO, etc.) often command a premium reflecting their reliability and performance consistency.

Raceway & Rolling Element Design: V-groove vs. flat raceway designs, roller diameter/length, and cage material/complexity influence cost.

Accessories & Services: Inclusion of seals, specialized lubrication, mounting hardware, or value-added services like pre-mounting or alignment checks adds to the total cost.

Partnering for Peak Performance: Sourcing Your Crossed Roller Bearings

Selecting the right supplier is as critical as choosing the bearing itself. This demands a partner with deep technical expertise, proven manufacturing capabilities, and a commitment to quality. Look for suppliers offering:

Broad Standard & Custom Capabilities: Ability to supply both catalog items and engineered-to-order solutions.

Precision Manufacturing Prowess: Expertise in grinding raceways and rollers to micron-level tolerances consistently.

Rigorous Quality Control: Comprehensive inspection protocols (dimensional, material, hardness, surface finish, rotational accuracy, torque) traceable to international standards.

Material Expertise: Knowledge in selecting appropriate steels and treatments for performance, longevity, and environment.

Technical Support: Engineering assistance for selection, integration, mounting guidance, and troubleshooting.

Reliability & Proven Track Record: Demonstrated performance in demanding applications across industries.

Supplier of Crossed Roller Slewing Bearings

For applications where compromise is not an option, LYRADRIVE stands as a premier provider of high-performance crossed roller slewing bearings. We specialize in delivering solutions that meet the most stringent requirements for precision, rigidity, and reliability. Our expertise encompasses:

Advanced Manufacturing: Utilizing state-of-the-art equipment and stringent processes to produce bearings with exceptional accuracy and consistency.

Precision Focus: Offering bearings from standard high-accuracy grades to ultra-high-precision optical alignment levels.

Custom Engineering: Collaborating closely with clients to design and manufacture bearings tailored to specific load, space, motion, and environmental constraints.

Uncompromising Quality: Implementing rigorous quality management systems and 100% critical dimension inspection for high-precision orders, ensuring every bearing meets exact specifications.

Material Selection: Supplying bearings in standard high-carbon chrome steel, corrosion-resistant stainless steel, and specialized alloys for optimal performance.

Global Support: Providing technical expertise and responsive service to partners worldwide.

LYRADRIVE understands that your machinery's performance hinges on the precision and reliability of its core components. We are dedicated to providing the crossed roller slewing bearing solutions that empower your innovations, enhance your productivity, and ensure your competitive edge in demanding markets. Contact LYRADRIVE to explore how our precision engineering can elevate your next project.