The LyraDrive Approach: Force Rational Design for Superior Slew Drives

Introduction

At the heart of modern machinery—from the cranes that build our cities to the wind turbines powering our future—lies a crucial component that makes controlled, powerful rotation possible: the slew drive. This compact yet mighty assembly acts as the "rotating joint" for heavy equipment, and its performance is fundamental to the machine's reliability and efficiency. At LyraDrive, we believe a superior slew drive isn't just manufactured; it's engineered from the ground up through a principle we call Force Rational Design. This means starting with the fundamental laws of mechanics to ensure every component is prepared for the real-world forces it will face.

1. What is Slew Drive?

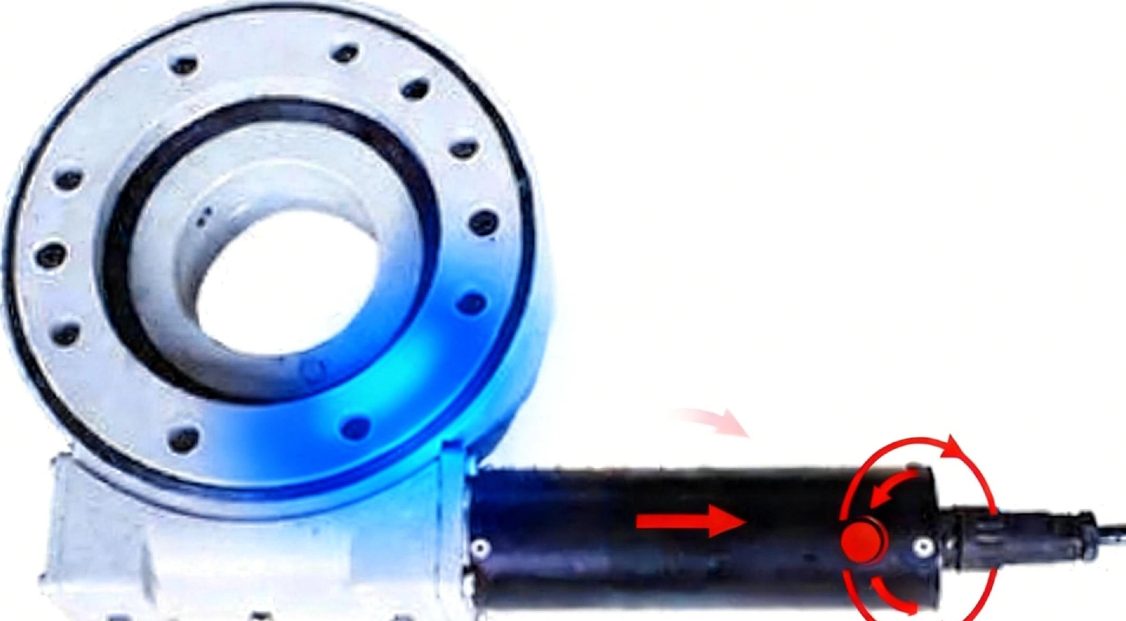

Imagine a remarkably strong "rotating joint"—one that must bear immense weight while also turning slowly and precisely. A slew drive is precisely that: an integrated power unit. It combines a large-diameter slew bearing with a compact gear reducer, all housed within a rugged casing. Its core mission is to provide powerful, smooth, and controlled low-speed rotation while simultaneously handling complex loads from all directions—axial, radial, and tilting moments. This all-in-one design makes it incredibly space-efficient and robust.

2. What are the Components of a Slew Drive?

To understand how it works, let's look at its key parts:

The Slew Bearing (The Load-Bearing Core): This is the "backbone" of the drive. It's a large bearing with a gear ring, directly carrying all the weight and external forces.

The Gear Set (The Power Driver): Usually a worm gear or spur gear. This small, active gear meshes with the large ring gear on the slew bearing, driving the entire assembly to rotate.

The Housing (The Strong Frame): This sturdy "house" holds all components together and safely transfers loads into the host machine's structure.

The Sealing System (The Longevity Guardian): Keeps dirt and water out while retaining lubrication, which is key to long-term, smooth operation.

3. How Does Slew Drive Work?

Its operation can be seen as a "force amplification" process:

Power Input: A motor (electric or hydraulic) starts, spinning the internal pinion gear at high speed.

Gear Engagement: This high-speed pinion gear meshes precisely with the large ring gear on the slew bearing. Because the ring gear is much larger, the rotational speed is greatly reduced, but the output twisting force (torque) is massively amplified.

Load Rotation: This amplified force drives the entire slew bearing, which ultimately rotates the attached platform or boom smoothly and powerfully. All the weight and force from the equipment are borne directly through the bearing's robust raceways, making the system incredibly stable and efficient.

4. How to Design a Superior Slew Drive Through Force Rationality?

"Force Rational Design" is our core engineering philosophy. It's more than just calculating a "maximum load"; it's a systematic process of analysis to ensure every bit of material is used where it's most needed.

Step 1: A Precise Force "Check-up"

We start by deeply understanding the equipment's real working conditions: How does it move? Where is the load's center of gravity? How do the forces change at each moment—during rotation, lifting, or stopping? We create a complete load spectrum, like a dynamic "force cardiogram" for the machine, not just looking at a single peak value.

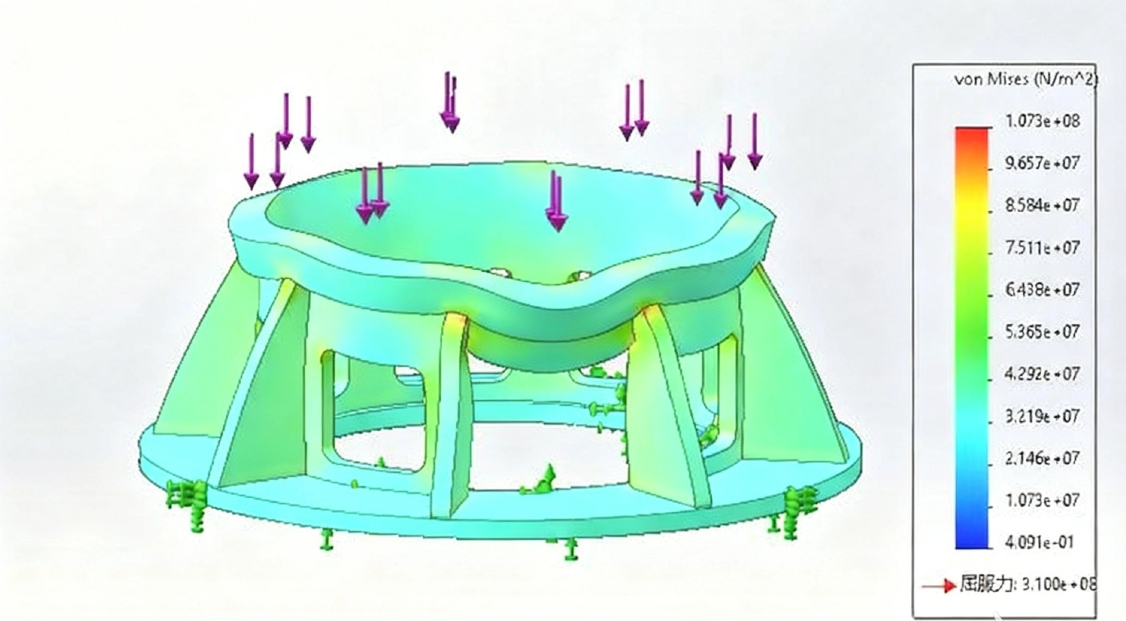

Step 2: Simulation with a Computer "X-ray"

Using Finite Element Analysis (FEA) software, we create a digital model of the slew drive. We then apply the various real-world forces from Step 1 to this virtual model. The software acts like an "X-ray," allowing us to see clearly:

How are forces distributed across the bearing and gears?

Where is the stress concentrated? Where are the potential weak points?

Under repeated loading, where might fatigue start?

Step 3: Validation with an Empirical Database

Computer simulation offers possibilities, but real-world data provides certainty. We maintain a vast database of mechanical performance, built from years of field-measured stress data and validated designs. We use this real data to calibrate and refine our simulation models, ensuring our digital "X-ray" shows a picture that closely matches real-world mechanical behavior.

Step 4: Holistic Optimization Based on Mechanics

With the precise "map" of force flow from the previous steps, we can optimize purposefully:

Selection & Layout: We choose the most rational bearing type (ball, roller, or cross roller) based on the primary force types.

Material & Process: We match the appropriate material grade and heat treatment to the stress levels each part will endure.

Structural Reinforcement: We add material thickness or ribs only where truly needed, achieving the best balance between strength and weight.

The essence of this process is transforming intangible mechanical principles into tangible, optimized component design.

5. The LyraDrive Approach: Your Force-Rational Solution

At LyraDrive, we translate this "Force Rational Design" process into tangible value for you. We are not just a manufacturer; we are your engineering partner for rotational motion solutions.

How We Work With You:

We prefer to get involved early in your equipment's design phase. Our engineers collaborate closely with your team to analyze the mechanical challenges of your application. You bring the application scenario and requirements; we contribute our specialized expertise in the mechanical design of slew drives. Through this collaboration, what we deliver is not just a product, but a customized solution that is thoroughly mechanically validated and perfectly matched to your machine.

What You Gain:

Greater Reliability & Safety: Rooted in precise control of real force conditions, operation is more stable, and the risk of unexpected failure is significantly reduced.

Better Performance-Cost Balance: We avoid the waste and weight of "over-engineering" and the risk of "under-designing," maximizing cost-effectiveness.

Longer Service Life: Every component is designed according to its actual "work intensity," leading to a longer overall lifespan and lower total cost of ownership.

Seamless Integration: We provide not just a drive unit but also installation guidance and support, ensuring it integrates perfectly into your overall system.

Choosing LyraDrive means choosing a solid, mechanically rational foundation for your core rotational motion. Let us drive your equipment's performance with rationality and expertise.