How Does 3D Modeling Contribute to the Design of Slewing Drives?

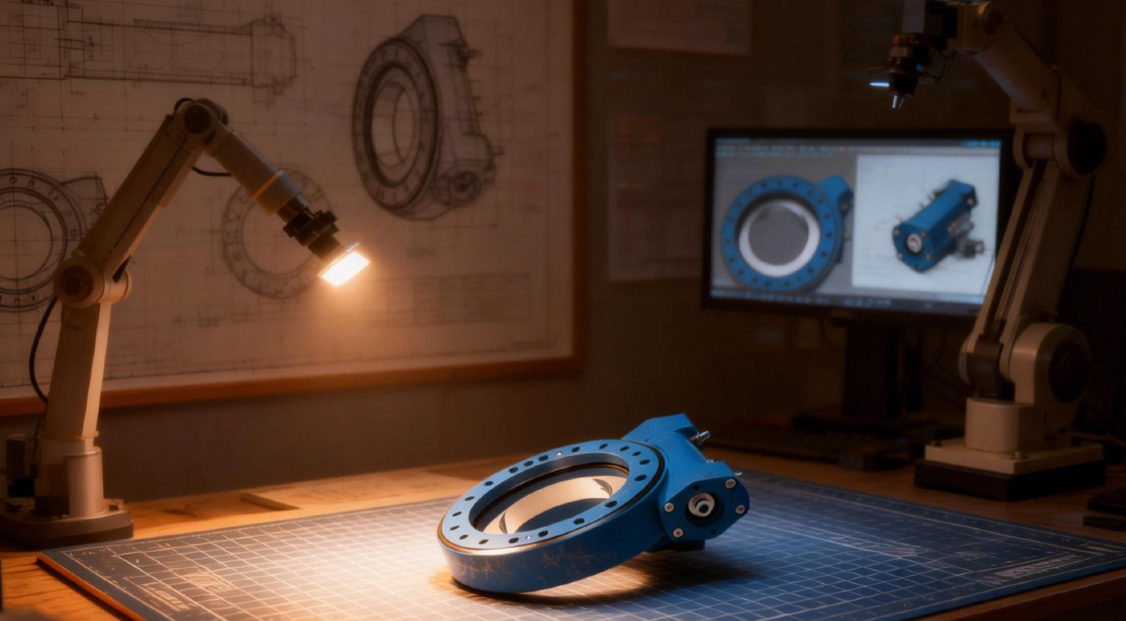

From the towering cranes on construction sites to the massive solar farms tracking the sun, reliable rotational motion is essential. At the heart of this motion lies a critical component: the slew drive. Designing this complex, load-bearing assembly requires precision, foresight, and collaboration. This is where 3D modeling technology has become an indispensable tool, fundamentally changing how engineers conceive, perfect, and deliver these powerful systems.

What is Slew Drive?

A slew drive is an integrated mechanical system that serves as a robust “rotating joint” for heavy machinery. It combines two primary functions into one compact unit: a slew bearing to support immense weight and multi-directional forces, and a gear reducer (like a worm or spur gear set) to provide controlled, high-torque, low-speed rotation. We can manufacture specialized slewing drives for various applications, such as truck crane slewing drives, excavator slewing drives, and slewing drives for solar tracking systems.

How Does Slew Drive Work?

The operation of a slew drive is a masterclass in mechanical advantage:

Input: A motor provides power to a small pinion gear.

Amplification: This pinion meshes with a large ring gear attached to the slew bearing. This interaction slows down the speed but massively increases the output torque.

Output: The amplified torque rotates the entire slew bearing and the machinery connected to it. The internal bearing seamlessly handles all the applied loads, making the system both powerful and durable.

How Can 3D Modeling Technology Be Applied to the Design of Slew Drives?

3D modeling is like giving engineers a digital workshop and crystal ball combined. Instead of starting with 2D drawings, designers now build a complete, precise, three-dimensional virtual model of the entire slew drive. This digital twin acts as the central hub for the entire design process, bringing concrete benefits in three key areas:

Boosting Engineer Efficiency and Capability: Working in 3D allows engineers to visualize, create, and modify complex assemblies far more intuitively and quickly than with flat 2D drawings. This enables rapid iteration and testing of different concepts, significantly accelerating the completion of intricate design tasks.

Enabling Clearer Client Communication and Faster Revisions: A 3D model serves as a universal visual language. Clients can clearly see the proposed design from any angle and understand how it integrates into their machine. This clarity facilitates immediate, precise feedback, allowing engineers to quickly identify and address design shortcomings and collaboratively lock down the optimal solution.

Ensuring Superior Product Performance and Quality from the Start: The 3D model is a precise digital prototype used for critical virtual validation. Engineers perform interference checks to prevent part collisions and run simulations (like FEA) to analyze stress and movement under real-world loads. This process identifies and resolves potential issues on the computer, ensuring the final physical product is built for reliable performance and meets the highest quality standards from the outset.

What are the Advantages of 3D Modeling Technology in the Design of Slew Drives?

The strategic application of 3D modeling translates into clear, competitive advantages:

Reduced Errors and Costs: Catching fit and interference issues digitally slashes the need for costly physical prototypes and manufacturing rework.

Optimized Performance: Virtual testing allows for data-driven refinement of the design for maximum strength, efficiency, and longevity.

Accelerated Development: Streamlined design, review, and manufacturing planning significantly shorten the time from concept to finished product.

Simplified Customization: Adapting base designs for specific client requirements becomes a faster, more accurate process within the flexible digital environment.

How Will LyraDrive Commit to Designing the Slew Drives Using 3D Modeling Technology?

At LyraDrive, our investment in 3D modeling technology is a direct investment in delivering precision, reliability, and partnership to our clients. We have integrated this tool into the core of our design philosophy.

Our 3D-Powered Design Commitment:

We utilize advanced 3D CAD and CAE software from the initial concept stage for every project, whether custom or standard. Your slew drive begins its life as a detailed digital twin, which we use to explore options, validate performance, and facilitate collaboration.

The LyraDrive Advantage for You:

Unmatched Clarity and Confidence: You will visualize and interact with a realistic model of your solution early on. We can provide animations and simulations, ensuring the design meets your expectations before manufacturing begins.

Inherent Reliability by Design: By applying rigorous FEA and motion simulation to our 3D models, we virtually "test" the drive to its limits, identifying and strengthening potential weak points to ensure the product you receive is optimized for durability.

A Streamlined Path to Success: The efficiency of 3D modeling accelerates the entire process—from concept and design validation to final manufacturing—reducing lead times and helping get your equipment into operation faster.

For LyraDrive, 3D modeling is the essential bridge between a challenging application and a robust, high-performance mechanical solution. It empowers us to partner with you more effectively, transforming complex rotational requirements into reliable drives. Let's build your next solution together, with digital precision paving the way to mechanical excellence.