How to Control Deformation in Slewing Drive Housing Castings

Introduction

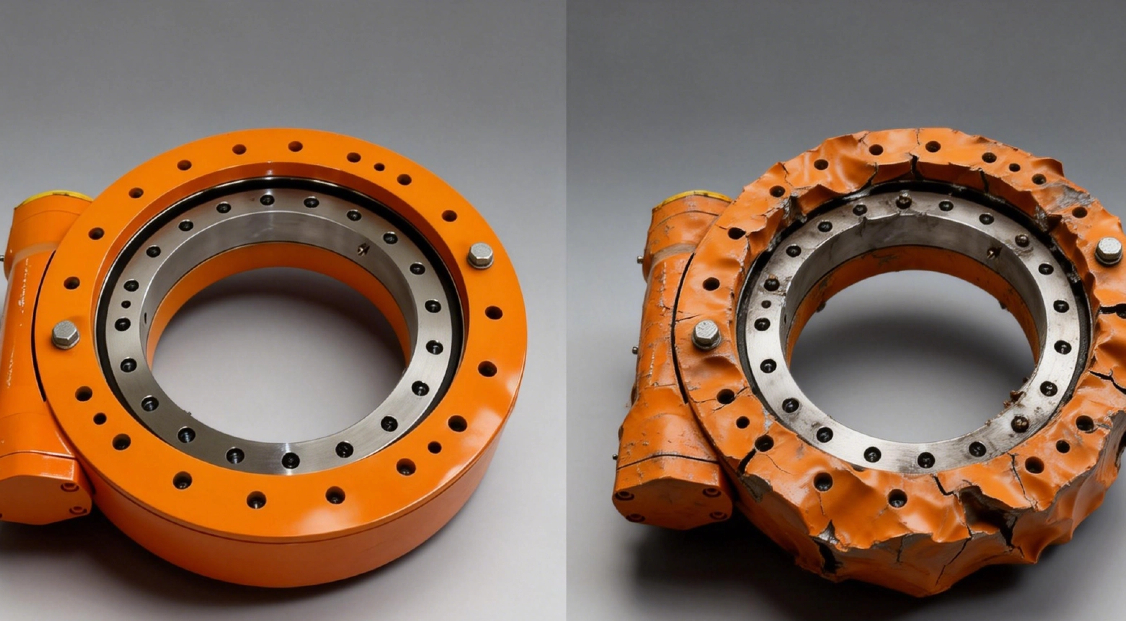

The performance of a slewing drive, which provides the essential rotation for equipment from cranes to solar trackers, relies on a solid foundation. That foundation is the housing casting. When this housing deforms, even slightly, it can lead to gear misalignment, increased wear, noise, and premature failure. Controlling such deformation is not just a manufacturing step—it's a fundamental principle for ensuring reliability and longevity. This article explains what causes housing deformation and the systematic methods used to prevent and control it, securing the performance of the entire system.

What is Slewing Drive?

A slewing drive is a compact, integrated gearbox that enables controlled, high-torque rotation for heavy machinery. It combines a slewing bearing (to handle massive axial, radial, and tilting loads) with a gear reducer (like a worm or spur gear set) into a single unit. This design efficiently supports heavy loads while providing powerful, slow-speed rotation, making it essential for applications like excavators, wind turbines, and material handling equipment.

What are the Components of a Slewing Drive?

To understand the housing's critical role, it helps to know the key parts it protects and aligns:

Slewing Bearing: The large bearing with an internal or external gear ring.

Worm or Pinion Gear: The driving gear that engages the bearing's gear ring to create rotation.

Housing: The structural casing that encloses all parts, provides mounting points, and maintains precise alignment.

Seals: Retain lubrication and keep out contaminants.

Motor & Brake: The power source and safety mechanism.

What Factors Cause Deformation in the Castings of Slewing Drive Housings?

Deformation occurs when internal stresses warp the housing's shape. These stresses originate from three main stages:

Design-Related Factors

Uneven Wall Thickness: Sections with different thicknesses cool at different rates. Faster-cooling thin sections can pull and warp slower-cooling thick sections.

Inadequate Support: Large, flat surfaces or unsupported spans lack rigidity and are prone to warping during cooling and under load.

Complex Shapes: Geometries with uneven mass distribution are more susceptible to uneven contraction.

Casting Process Factors

Mould Design: If the mould doesn't accurately account for the metal's shrinkage rate, the final part will be the wrong size and shape.

Pouring & Cooling Control: Uneven pouring temperatures or uncontrolled cooling speeds create internal temperature differences, leading to uneven contraction and stress.

Sand Core Issues: In sand casting, shifting or weak internal sand cores can cause variations in wall thickness.

Post-Casting Factors

Heat Treatment: The high temperatures used for stress relieving or hardening can cause new distortion if the part isn't uniformly heated or properly supported.

Machining Stress: Removing large amounts of material during final machining can release internal stresses, causing the part to twist or bend.

How to Control Deformation in Slewing Drive Housing Castings?

Effective deformation control is a multi-stage process from initial design to final inspection.

Prevention Through Optimized Design & Simulation

The best control happens before manufacturing begins.

Computer Simulation (FEA): Engineers use software to simulate thermal and mechanical stresses during casting and operation. This predicts warpage and allows for design improvements digitally.

Design for Manufacturing (DFM): Key principles include maintaining uniform wall thickness, using gradual transitions between sections, strategically adding ribs and stiffeners for rigidity, and designing symmetrical shapes for even cooling.

Precision in the Casting Process

Meticulous control during production is crucial.

Advanced Mould Engineering: Moulds are designed with precise shrinkage allowances and optimized channels to ensure smooth, uniform metal flow and solidification.

Strict Process Control: Key parameters like mould temperature, pouring temperature, and cooling rate are strictly monitored to minimize thermal shock and stress.

Post-Casting Correction & Verification

Stress Relieving: Castings undergo controlled heat treatment to release internal stresses before final machining.

Precision Machining: The first machining step creates a stable, true reference surface. All subsequent critical machining (like bearing seats) is done relative to this single reference, ensuring perfect alignment.

Final Inspection: Finished housings are checked with precision tools like Coordinate Measuring Machines (CMM) to verify all dimensions and flatness are within strict tolerances.

Summary of Deformation Control Methods

| Control Stage | Primary Methods | Key Objective |

|---|---|---|

| Design & Simulation | FEA Analysis, Uniform Walls, Strategic Ribbing | Predict and prevent deformation at the source. |

| Casting Process | Precision Mould Design, Controlled Pouring & Cooling | Minimize stress during manufacturing. |

| Post-Casting | Stress Relieving, Reference-Based Machining, CMM Inspection | Ensure final geometric accuracy. |

LyraDrive is Committed to Designing High-Quality Slewing Drives

Mastering the control of housing deformation is a cornerstone of our engineering philosophy at LyraDrive. It represents our core expertise in ensuring that every slewing drive we produce is built upon a perfectly stable and precise foundation. This deep-seated knowledge in material science, precision manufacturing, and structural integrity allows us to deliver products that offer our clients unparalleled reliability and durability in the most demanding applications.