The Advantages of Using Planetary Gearboxes for Slew Drives

What is Slew Drive?

In the fields of construction machinery, renewable energy, and heavy industrial equipment, a slew drive is a compact yet powerful mechanical component designed to handle one of the most challenging tasks in engineering: rotating heavy loads slowly, smoothly, and precisely.

A slew drive is essentially an integrated system that combines a slewing bearing (which supports the load) with a driving mechanism (such as a worm or gear set). What makes it unique is its ability to simultaneously handle axial forces, radial forces, and tipping moments in a single unit. You will find slew drives at work everywhere: they turn the boom of a crane, tilt the platform of an aerial work vehicle, rotate solar panels to follow the sun, and adjust the yaw angle of wind turbines. In short, wherever large masses need to move with control, a slew drive is likely at the heart of the system.

How Does a Slew Drive Work?

The working principle of a slew drive is essentially about converting high-speed, low-torque input into low-speed, high-torque output. The input typically comes from a hydraulic motor or an electric motor, and the output is the rotation of the gear ring or flange that carries the load.

At LyraDrive, we specialize in two main types of slew drive products. The first is the worm gear slew drive, which uses a worm shaft meshing with a worm wheel. This design is widely favored for its compact shape and its natural self-locking property—meaning the load cannot back-drive the motor, a critical safety feature for applications like cranes and lifts. The second is the spur gear slew drive, which uses a pinion gear to drive the external or internal teeth of the slewing bearing. This type offers higher efficiency and is better suited for continuous rotation applications.

Regardless of the type, the core task remains the same: the motor drives the input shaft, the gear mechanism amplifies the torque, and the slewing bearing translates that force into controlled rotational motion.

Why Pair a Gearbox with a Slew Drive?

As machine design becomes increasingly demanding, engineers often face a common dilemma: the need for greater torque and a higher reduction ratio, but with less space and a smaller motor. This is where the question of pairing a gearbox arises.

A standard slew drive, especially a worm gear type, has a fixed reduction ratio determined by the worm and wheel. When the required ratio exceeds what a single stage can provide—or when the input motor needs to operate at a more efficient RPM range—simply enlarging the drive is not the answer. The smarter solution is to add a gearbox between the motor and the slew drive input.

Adding a gearbox offers three distinct advantages. First, it multiplies the total reduction ratio without enlarging the slew drive itself. Second, it increases torque density, meaning you get more power from a smaller overall package. Third, it standardizes the interface, allowing off-the-shelf motors to be easily mounted onto custom drive solutions. The gearbox acts as a bridge—translating the motor’s language of speed into the slew drive’s language of torque.

What is a Planetary Gearbox?

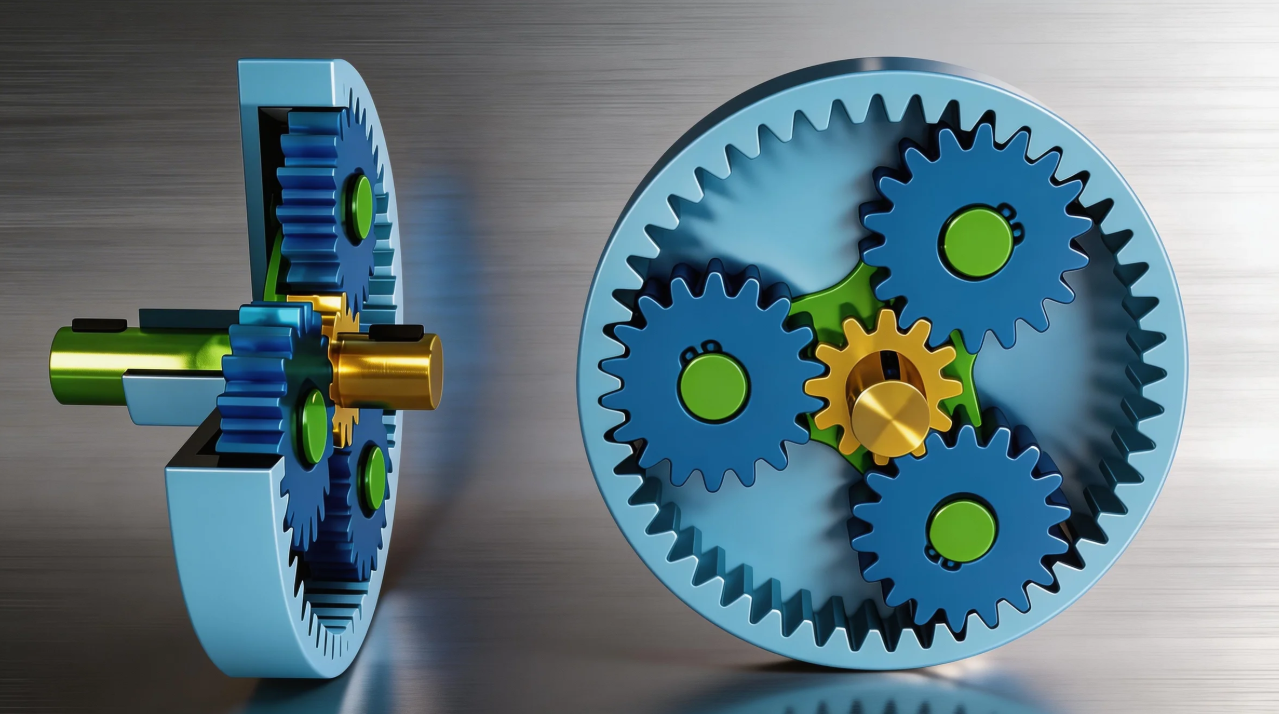

Among the various types of gearboxes available, the planetary gearbox (also known as an epicyclic gearbox) stands out for its ingenious design and exceptional performance density. Its name comes from its resemblance to the solar system: a central sun gear, multiple planet gears carried by a rotating planet carrier, and an outer ring with internal teeth called the ring gear.

The beauty of this design lies in its parallelism. When the sun gear turns, it drives all the planet gears simultaneously. These planet gears rotate on their own axes while also revolving around the sun gear, distributing the load across multiple contact points. The output is typically taken from the planet carrier (or sometimes the ring gear), depending on the desired ratio.

Because the input torque is split among several planet gears, planetary gearboxes can transmit significantly higher torque than comparably sized conventional gearboxes. They are also more compact, more efficient, and offer exceptional co-axiality since the input and output shafts share the same center line. These characteristics make the planetary gearbox not just a component, but a performance multiplier.

Key Features of Planetary Gearboxes for Slew Drives

When a planetary gearbox is specifically engineered for integration with a slew drive, it exhibits several distinct design features that set it apart from general-purpose planetary reducers.

High radial load capacity is one such feature. Unlike standard gearboxes that are designed to transmit pure torque, a slew-drive planetary gearbox must often support overhung loads from the motor or external forces. This requires reinforced bearings and robust housing construction, typically using nodular cast iron for superior rigidity and shock resistance.

Compact axial length is another critical feature. In applications like excavators or wind turbines, every millimeter of space matters. Planetary gearboxes designed for slew drives are often tailored to have minimal protrusion from the drive housing, allowing for easier installation inside tight machinery compartments.

Sealing and environmental protection are equally vital. Slew drives frequently operate outdoors or in dusty, wet conditions. A high-quality planetary gearbox for this application will feature multi-lip seals, corrosion-resistant coatings, and sometimes even integrated breather valves to handle temperature and pressure changes.

Modularity is the final hallmark. A well-designed planetary gearbox should allow for multiple stages of reduction and flexible input interfaces, enabling customers to mix and match components to achieve the exact speed ratio and mounting configuration they need.

How Does a Planetary Gearbox Work in a Slew Drive?

To understand how a planetary gearbox functions within a slew drive system, picture the complete power flow path.

The journey begins with the prime mover—an electric or hydraulic motor. This motor drives the input shaft of the planetary gearbox at relatively high speed. Inside the gearbox, the sun gear spins, engaging the planet gears. Because the ring gear is fixed to the gearbox housing, the planet gears are forced to walk around the inside of the ring gear, carrying the planet carrier with them. This carrier rotates at a reduced speed but with multiplied torque.

Now comes the integration point. The output shaft or flange of the planetary gearbox is directly connected to the input shaft of the slew drive. This connection can be a keyed shaft, a splined interface, or a bolted flange, depending on the design. The now-amplified torque enters the slew drive, where a second stage of reduction occurs—either through the worm/wheel set or the pinion/gear ring interface. The final result is an extremely low-speed, high-torque rotation delivered precisely to the load.

This two-stage reduction strategy is what makes the combination so powerful. The planetary gearbox handles the high-speed multiplication stage efficiently, while the slew drive handles the final heavy lifting. Together, they form a compound system that is far more capable than either component alone.

Core Advantages of Using Planetary Gearboxes for Slew Drives

When a planetary gearbox is paired with a slew drive, the resulting system gains a set of distinct performance advantages that are difficult to achieve with other transmission technologies.

Wide transmission ratio range. Planetary gearboxes can achieve very high reduction ratios in a single stage, and even more when staged. This allows designers to select from a broad spectrum of speed/torque combinations without changing the physical size of the slew drive itself.

Compactness and light weight. Because the planetary design distributes load across multiple gears, the power density is exceptionally high. A planetary gearbox can deliver the same torque as a conventional parallel-shaft gearbox in a package that is significantly smaller and lighter. This is invaluable in mobile equipment where weight and space are at a premium.

Smooth and quiet operation. The symmetrical arrangement of planet gears cancels out many of the unbalanced forces found in other gear types. Multiple teeth are always in contact, sharing the load and smoothing out the transmission of power. This results in lower vibration and noise levels—a critical factor in urban construction equipment and precision tracking systems.

High efficiency. Planetary gearboxes typically achieve efficiency ratings of 95% to 98% per stage. This means less energy is lost as heat, and more of the motor’s power reaches the load. In solar tracking applications, where every watt of self-consumption matters, this efficiency translates directly into better energy payback.

Robustness and durability. With ductile iron housings, hardened and ground gears, and high-quality bearings, planetary gearboxes are built to survive shock loads, continuous duty cycles, and harsh environments. They maintain consistent performance even under extreme temperatures, moisture, and contamination.

Modular and scalable. The planetary system allows for great design flexibility. Multiple stages can be stacked to increase ratio. Input and output interfaces can be customized. The same basic gearbox design can be adapted to fit a wide range of slew drive sizes and motor types, simplifying inventory and maintenance.正在阅读

How to Choose Planetary Gearboxes for Your Slew Drive Application?

Selecting the right planetary gearbox for a slew drive is not a matter of guesswork—it is a systematic process based on application data. To ensure reliable performance and long service life, the following key parameters must first be defined: output torque, motor power, input speed, output speed, operating conditions (including start-ups per hour and shock loads), ambient temperature, and any radial or thrust loads on the shafts.

Step 1: Determine the reduction ratio.

This is calculated as Input Speed ÷ Output Speed. If output torque is unknown, it can be derived from power and speed.

Step 2: Calculate the required output torque.

Use the formula:

Output Torque (Nm) = (Power in kW × 9549) ÷ Output Speed (RPM)

(If power is given in HP, multiply by 0.746 to convert to kW.)

Step 3: Apply the service factor.

Based on your application type and daily duty cycle, select an appropriate service factor (SF). This compensates for shock loads and varying operating conditions.

Step 4: Determine the rated torque.

Rated Torque = Calculated Output Torque × Service Factor.

This is the torque value the gearbox must be capable of handling continuously.

Step 5: Select the model from engineering data.

Match the rated torque and required service life (in hours) against the manufacturer’s performance tables to identify a suitable frame size and stage configuration.

Step 6: Verify thermal capacity.

Ensure the gearbox can dissipate heat under continuous operation. Compare the thermal power rating (at standard ambient conditions) with your actual input power.

Step 7: Check interface and mounting constraints.

If a hollow input or special flange is required, confirm compatibility with your motor and slew drive input dimensions.

Step 8: Validate overhung load capacity.

When the output is connected to a sprocket, pulley, or pinion, calculate the overhung load using:

Overhung Load (N) = [(19,100,000 × Power in kW) ÷ (Pitch Diameter in mm × Shaft Speed in RPM)] × Load Connection Factor.

Ensure this value does not exceed the gearbox’s rated overhung load.

Following this structured approach ensures that the planetary gearbox you select is not only dimensionally correct but also thermally and mechanically matched to your specific slew drive application. At LyraDrive, we apply this exact engineering methodology to every custom solution we develop—ensuring that the gearbox stage integrated into your slew drive is precisely sized, not over-specified or under-sized. Whether you need a compact worm gear drive or a high-efficiency spur gear configuration, our team works directly from your application parameters to deliver a fully matched, ready-to-mount drivetrain solution.

LyraDrive: Customised Slew Drive Manufacturer

At LyraDrive, we understand that every application tells a different story. A crane in a shipyard, a solar tracker in the desert, an excavator in a mine—each demands a unique balance of torque, precision, and durability. That is why we have built our reputation around customised slew drive and slewing bearing manufacturing.

Our product portfolio centers on two core components: slew drives and slew bearings. Within our slew drive family, we offer two primary configurations. The worm gear slew drive delivers exceptional self-locking capability and smooth motion control, ideal for applications requiring holding torque and positional stability. The spur gear slew drive provides higher efficiency and is optimized for continuous, high-duty-cycle operations where energy conservation is paramount.

What sets LyraDrive apart is not just the components we make, but how we make them. Every unit we produce is tailored to the customer’s specific requirements—whether it is a modified mounting flange, a specialized sealing solution, a unique paint system for marine environments, or an integrated planetary gearbox stage precisely matched to the motor interface. We do not believe in forcing your application to fit our catalog. Instead, we engineer our drives to fit your machine.

When you choose LyraDrive, you are choosing more than a component. You are choosing a partner with deep technical knowledge, flexible manufacturing capabilities, and a commitment to quality that runs through every gear tooth, every seal, and every housing we produce. From concept to commissioning, we work alongside you to ensure that your slew drive system performs exactly as intended—today, tomorrow, and for years to come.