Slewing Ring vs. Bearing: A Comprehensive Guide for Engineering Selection

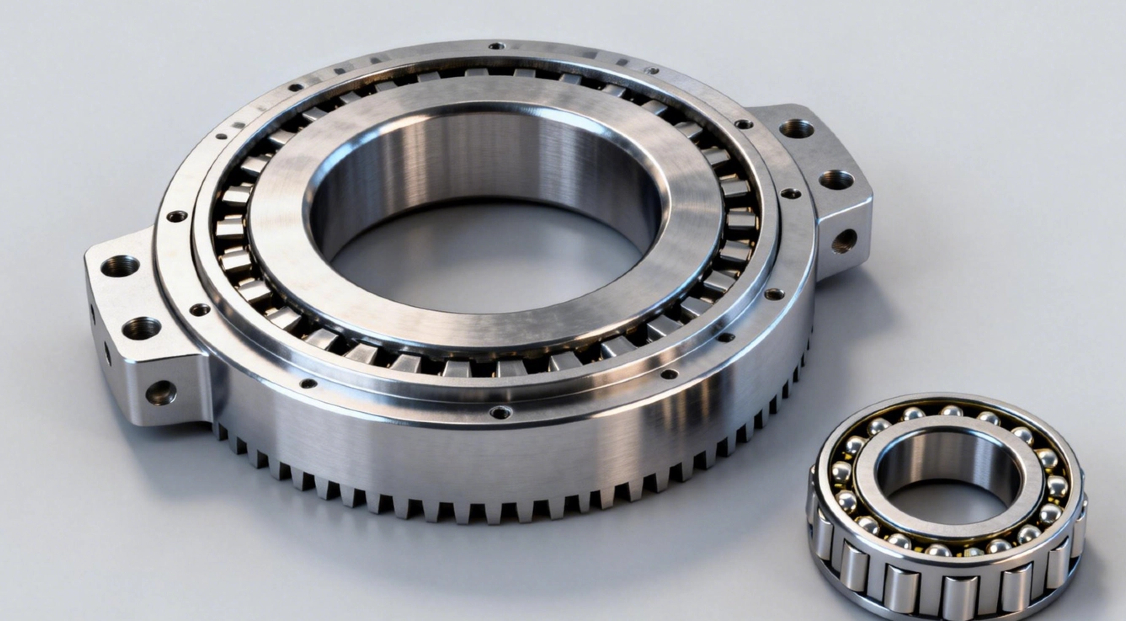

When designing machinery that requires rotational movement, a critical decision arises: should you use a slewing ring or a standard bearing? While both components facilitate rotation, they are engineered for vastly different operational demands. This guide will clarify their distinct characteristics, compare their applications, and provide a framework for selecting the optimal component for your project.

What are Slewing Rings?

Slewing rings, also known as slewing bearings, are large-diameter, integrated rotational bearings. They are engineered as complete, ready-to-mount assemblies designed to handle simultaneous multi-directional loads—specifically axial (thrust), radial, and tilting moment loads. Unlike standard bearings, their robust construction often includes integral gear teeth (internal or external), mounting holes, and sealing systems.

Characterized by their large size and slow rotational speed, they are fundamental components in heavy-duty machinery where structural support and rotation under immense weight are paramount. Their design allows them to act as both a rotational joint and a structural connection point between the upper and lower parts of a machine.

What are Bearings?

In a broader sense, bearings are mechanical components that constrain relative motion to only the desired direction (typically rotation) and reduce friction between moving parts. In the context of this comparison, we refer to standard rolling-element bearings, such as deep groove ball bearings or tapered roller bearings.

These components are generally smaller, standardized, and optimized for high rotational speeds. Their primary function is to support a shaft and facilitate its smooth, efficient rotation while carrying predominantly radial or axial loads—though rarely large combinations of both simultaneously. They are the workhorses inside countless motors, gearboxes, wheels, and general industrial machinery.

Comparison of Slew Rings and Bearings in Application Fields

The most practical distinction lies in their typical applications. The following table illustrates where each component is predominantly used:

| Comparison Aspect | Worm Gear Slewing Drive | Spur Gear Slewing Drive |

|---|---|---|

| Core Principle | Sliding contact between worm and wheel. | Rolling contact between meshing gear teeth. |

| Transmission Efficiency | Relatively Low (30% - 45%). Higher energy consumption. | Very High (90% - 95%). Energy efficient. |

| Reduction Ratio | Very High in a single stage. | Moderate. High ratios may require complex designs. |

| Self-Locking | Inherently self-locking. Safe for static load holding. | Not self-locking. Requires an external brake. |

| Operational Speed | Low speed (typically ≤ 2-5 RPM). Prone to overheating at high speed. | High speed capable (often 40-60 RPM). |

| Precision & Backlash | Higher inherent backlash. Difficult to achieve high precision. | Can achieve high precision and low backlash (<0.01°). |

| Key Advantages | High ratio, self-locking, compact, right-angle input/output. | High efficiency, high speed, high precision, long life. |

| Key Limitations | Lower efficiency, heat generation, speed limits. | No self-lock, needs brake, complex for high ratios. |

The Key Differences Between Slewing Rings and Bearings

Building on the application comparison, the core technical differences can be summarized as follows:

1. Load Capacity and Type: This is the fundamental difference. Slewing rings are built to manage large combined loads (axial, radial, and moment) at once. Standard bearings are typically optimized to handle either predominantly radial OR axial loads effectively.

2. Size and Integration: Slewing rings are large, custom-engineered assemblies that often incorporate gears and mounting provisions. Standard bearings are compact, mass-produced components designed to be fitted into housings.

3. Rotational Speed: Slewing rings operate in slow or moderate-speed environments (often measured in RPM). Standard bearings are designed for medium to very high rotational speeds.

4. Function in the System: A slewing ring often forms the critical rotational interface between two major structures (e.g., a crane's cab and its undercarriage). A standard bearing is usually a component that supports a rotating shaft within a larger system.

How to Select the Right Component for Rotational Motion?

Making the correct choice hinges on a clear analysis of your application's requirements. Follow this decision framework:

1. Analyze the Loads: Identify the magnitude and direction of all acting loads.

Choose a Slewing Ring if your application involves slow rotation while supporting heavy combined loads (e.g., a crane lifting and slewing a load).

Choose a Standard Bearing if the primary requirement is supporting high-speed rotation with relatively simpler, directional loads (e.g., a fan motor shaft).

2. Consider Size and Space Constraints: Evaluate the available envelope.

Choose a Slewing Ring for large-diameter, low-profile rotation where the bearing itself provides the mounting surface (e.g., a turntable).

Choose a Standard Bearing for compact assemblies where the bearing fits into a dedicated housing on a shaft.

3. Review Speed and Motion Profile: Determine the required rotational speed and motion (continuous, oscillating, indexing).

Choose a Slewing Ring for slow, precise positioning or continuous slow-speed rotation under load.

Choose a Standard Bearing for smooth, continuous high-speed rotation.

LyraDrive: Your Trusted Partner for Precision Slewing Solutions

At LyraDrive, we understand that the performance of your heavy-duty equipment hinges on the reliability of its core rotational components. As a specialized manufacturer of high-performance slew rings (slew bearings), we are dedicated to providing more than just a product—we deliver engineered solutions that bear the load, so you don't have to.From initial design consultation to final installation support, we partner with you to ensure seamless integration, optimal performance, and long-term durability in your most demanding applications.

Our Product Philosophy:

We focus on precision engineering and robust manufacturing. Our slew rings are characterized by:

Superior Load Management: Engineered to handle the most demanding combinations of axial, radial, and moment loads.

Custom-Engineered Designs: We provide tailored solutions, offering integrated gearing (spur or helical), custom sealing systems for harsh environments, and various mounting configurations.

Material Excellence: Utilizing high-grade, case-hardened steels and advanced heat treatment processes to ensure exceptional durability and long service life.

Rigorous Quality Assurance: Every bearing undergoes stringent inspection and testing, guaranteeing performance and reliability from the first rotation to the last.

What We Bring to Your Project:

Choosing LyraDrive means partnering with a team committed to your success. We offer:

Application Engineering Support: Our technical experts work with you from the design phase to select or design the optimal slew ring for your specific load, speed, and environmental conditions.

Proven Reliability in Critical Applications: Our bearings are trusted in sectors where failure is not an option, including wind energy, industrial robotics, and heavy construction.

Global Supply with Localized Service: We ensure timely delivery and provide dedicated after-sales support to keep your operations running smoothly.

For your next project that demands robust, reliable, and precise rotational motion, look to the experts at LyraDrive. Let us help you build the foundation upon which your machinery's performance revolves.