How does gear radial runout affect the operation of a slew drive?

For any heavy machinery relying on a slew drive for smooth, controlled rotation—from the precise positioning of a solar tracker to the powerful swing of a crane—performance hinges on the accuracy of its components. One critical yet often overlooked factor that can significantly degrade this performance is gear radial runout. Understanding and controlling this parameter is essential for ensuring the reliability, efficiency, and longevity of the entire system.

1. What is radial runout in gears?

Radial runout refers to a deviation in the rotation of a gear. Specifically, it measures how much the pitch circle of a gear (the imaginary circle upon which gear teeth are spaced) wobbles or shifts away from a perfect, true rotation around its central axis. You can visualize it as the gear not spinning "true," but with a slight eccentricity. This geometric error introduces instability and inconsistency into what should be a smooth and uniform rotary motion, acting as a primary source of vibration and uneven force transmission within the gear train.

2. Why does radial runout occur in gears?

Radial runout is typically not the result of a single error but a cumulative effect of deviations introduced during various stages of a gear's lifecycle:

Manufacturing Imperfections: This is the most common origin. Inaccuracies in the gear cutting, hobbing, or grinding processes can lead to an eccentric mounting of the gear blank on the machining arbor, or inconsistencies in the machining itself.

Heat Treatment Distortion: The intense heat and quenching processes used to harden gears can cause internal stresses and subsequent warping or distortion, altering the gear's perfect cylindrical form.

Inadequate or Improper Installation: Even a perfectly manufactured gear can develop runout if it is not mounted correctly onto its shaft. Causes include a poorly machined shaft, the presence of burrs or debris between the gear hub and shaft, uneven tightening of mounting bolts, or misalignment during the assembly process.

Bearing and Component Wear: During operation, wear in supporting bearings, deformation of the gear housing, or shaft deflection under load can all introduce or exacerbate radial runout over time.

3. What effect does gear radial runout have on gear transmission?

The consequences of excessive radial runout are systemic and detrimental, impacting the slew drive across multiple critical performance areas:

Unstable and Uneven Transmission: Runout causes periodic fluctuations in the center distance between the pinion and the large gear ring. This results in an unsteady transmission of motion, leading to speed irregularities and torque pulsations. This instability directly compromises the operational uniformity of the slew drive, reducing the precision and smoothness of the equipment it controls.

Increased Impact, Wear, and Noise: The fluctuating meshing conditions create repeated impacts between the gear teeth. This accelerates wear on the tooth flanks, leading to premature pitting and surface degradation. Furthermore, these impacts and the unstable meshing generate significantly elevated noise levels, which pollutes the work environment and can indicate ongoing damage.

Excessive Vibration and Premature Fatigue: Radial runout is a direct source of mechanical vibration. These vibrations are not only a nuisance but also transmit destructive forces through the slew drive into the host machinery. This leads to accelerated material fatigue in gears, bearings, and structural components, drastically shortening the service life of the entire system and increasing the risk of unexpected failure.

4. How to resolve the issue of gear radial runout?

Mitigating radial runout requires a proactive, precision-focused approach throughout the gear's lifecycle:

Prioritize Precision in Manufacturing: Source gears from manufacturers who employ high-precision machining centers, rigorous process controls, and advanced gear grinding technology. Specifying tighter tolerance grades for gear accuracy is a fundamental first step.

Master the Installation Process: Follow meticulous installation procedures. Ensure shafts and mounting surfaces are clean, smooth, and free of damage. Use precision alignment tools (like dial indicators) to check for and correct runout after the gear is mounted, and ensure all fasteners are torqued evenly and to specification.

Implement Rigorous Quality Control: Incoming inspection of gears using runout gauges is crucial to reject components that do not meet specifications. Regular preventative maintenance on the slew drive, including checks for abnormal noise, vibration, and backlash, can help identify issues stemming from developing runout before they cause catastrophic failure.

Design for Stability: In critical applications, consult with experts on design considerations that can improve stability, such as optimal gear geometry, proper bearing selection for maximum support, and housing designs that minimize deflection under load.

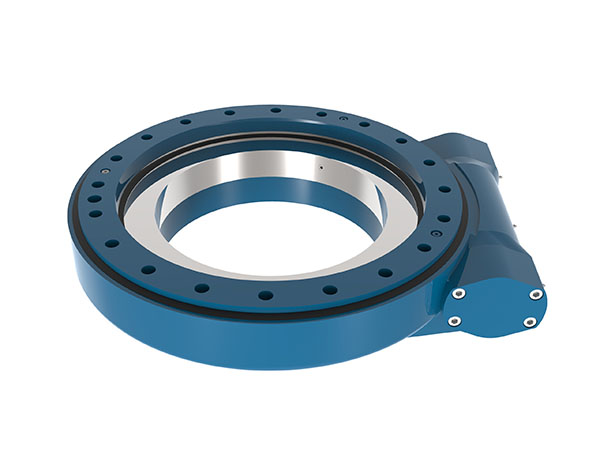

5. LyraDrive can provide you with the optimal solution

Addressing gear radial runout effectively requires more than just following guidelines; it demands partnership with a manufacturer that builds precision into its core philosophy. At LyraDrive, as a specialist in engineered slew drives and slew bearings, we understand that flawless rotation begins with flawless components.

Our solution starts with the integrated manufacturing of the gear ring directly onto the slew bearing raceway using state-of-the-art CNC gear grinding machines. This process eliminates the cumulative errors inherent in assembling separate gear and bearing components. Every gear tooth profile is finished to exacting tolerances, ensuring minimal radial runout from the outset. Furthermore, our engineers perform 100% inspection of critical parameters, including radial runout, on high-precision coordinate measuring machines (CMM) before assembly. This guarantees that every LyraDrive unit delivers the smooth, stable, and reliable performance your application demands, effectively neutralizing the problems of vibration, uneven wear, and premature fatigue at their source.

Partner with LyraDrive to ensure your machinery is powered by precision. Let us provide the stable, high-integrity rotational foundation that maximizes your equipment's uptime, accuracy, and lifespan.