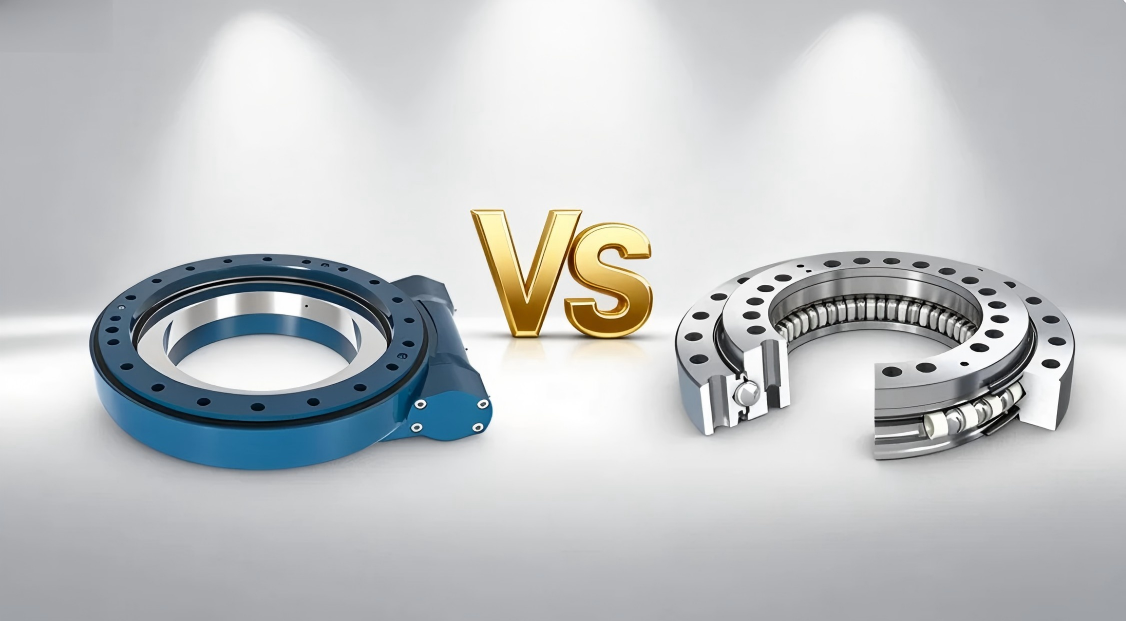

Slewing Bearings vs. Slew Drives: Understanding the Key Differences

Introduction

In the realm of mechanical engineering and industrial machinery, rotation is a fundamental motion that enables a wide range of applications, from heavy lifting to precise positioning. Two critical components that facilitate rotational movement are slewing bearings and slew drives. While both are integral to systems requiring rotation, they serve distinct roles and operate on different principles. Often, they are used in conjunction to achieve efficient and flexible rotational functionality, but they are also deployed separately in diverse scenarios. This article delves into the definitions, functions, comparisons, and selection criteria for slewing bearings and slew drives, providing a comprehensive guide for engineers, designers, and industry professionals.

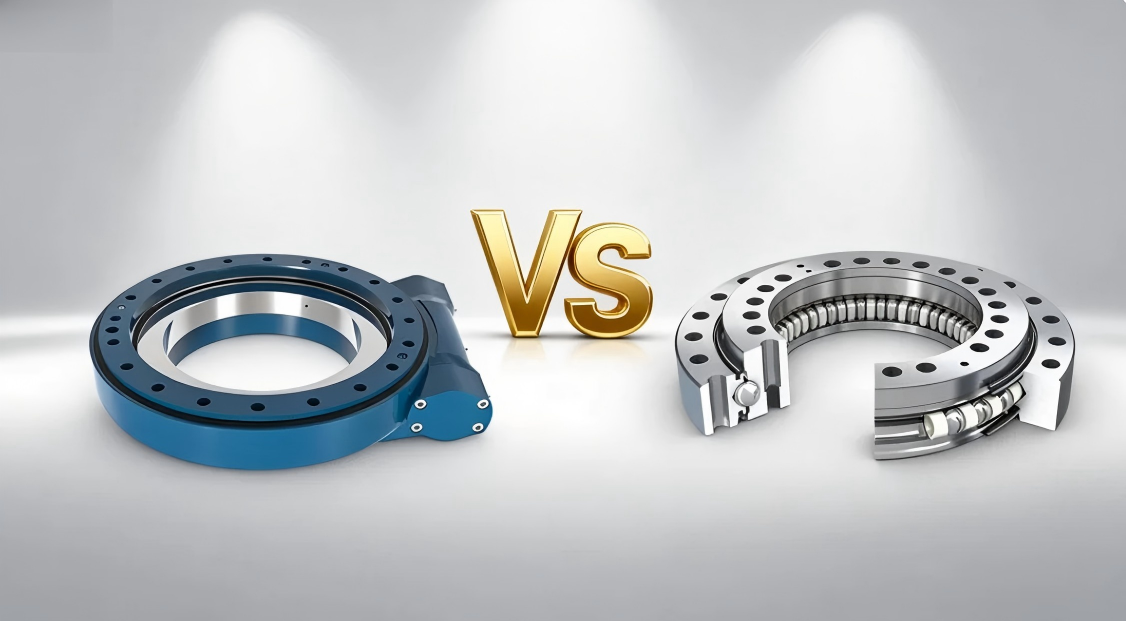

What Are Slewing Bearings?

A slewing bearing, also known as a slewing ring or turntable bearing, is a specialized bearing designed to support heavy loads and manage torque in rotational structures. Unlike conventional bearings, slewing bearings can handle combined loads—including axial, radial, and moment loads—simultaneously. This makes them suitable for applications where the bearing must endure significant weight and rotational forces.

Slewing bearings consist of an inner ring, an outer ring, rolling elements (such as balls or rollers), and often include gear teeth integrated into one of the rings. These gears enable the bearing to be driven by a pinion, facilitating controlled rotation. The bearings are engineered to operate in various orientations: horizontal, vertical, or inclined axes.

Common applications of slewing bearings include:

Cranes and excavators in construction

Wind turbines for yaw and pitch control

Solar tracking systems for optimal energy capture

Rotating platforms in amusement rides

Military equipment like turrets and radar antennas

The durability and load-bearing capacity of slewing bearings make them indispensable in heavy-duty industries. They are typically custom-designed to meet specific load, speed, and environmental requirements.

What Are Slew Drives?

A slew drive is a compact, integrated mechanical drive system that enables rotational movement. It combines several components into a single unit: a slewing bearing, a gear reduction system (such as a worm gear or planetary gear), an electric or hydraulic motor, and often a brake or locking mechanism. The primary function of a slew drive is to provide controlled, high-torque rotation with precise speed and positioning.

Slew drives are designed to not only support loads but also drive them, making them an all-in-one solution for applications requiring both motion and structural support. The integrated gear reduction allows for high torque output at low speeds, which is essential for heavy-load rotation.

Common applications of slew drives include:

Tower cranes and concrete pump trucks

Aerial work platforms and manlifts

Satellite and antenna positioning systems

Robotics and automated manufacturing

Medical imaging equipment like CT scanners

Slew drives offer advantages in terms of space efficiency, simplified installation, and enhanced control. They are particularly useful in applications where precision, reliability, and compact design are critical.

Comparison of Slewing Bearings and Slew Drives

The table below summarizes the key differences between slewing bearings and slew drives:

| Aspect | Slewing Bearings | Slew Drives |

|---|---|---|

| Primary Function | Support loads and facilitate rotation | Drive and control rotation with integrated power |

| Components | Bearing rings, rolling elements, gear teeth (optional) | Slewing bearing, gear reducer, motor, brake, housing |

| Load Capacity | High axial, radial, and moment loads | High torque and load capacity, but design-dependent |

| Drive Mechanism | Requires external motor and gear system | Built-in motor and reduction system |

| Precision & Control | Limited to bearing accuracy; control depends on system | High precision with integrated control capabilities |

| Installation | Requires assembly with separate drive components | Pre-assembled |

| Customization | Highly customizable for load and size | Customizable for torque, speed, and control features |

| Cost | Generally lower cost per unit | Higher due to integrated components |

| Maintenance | Regular lubrication and inspection | Requires maintenance of gears, motor, and bearing |

| Applications | Cranes, excavators, solar trackers, rotating platforms | Cranes, aerial platforms, radar systems, robotics |

This comparison highlights that slewing bearings are primarily passive components focused on load support, while slew drives are active systems that provide driven motion. The choice between them depends on whether the application requires mere rotational support or a complete drive solution.

Factors to Consider When Choosing Between Slewing Bearings and Slew Drives

Selecting the appropriate component—slewing bearing or slew drive—is crucial for optimal performance, safety, and cost-effectiveness. Below are key factors to consider:

(1) Load and Torque Requirements

Slewing Bearings: Ideal for applications with high static or dynamic loads but where torque is provided externally. They excel in supporting heavy structures, such as in cranes or turntables.

Slew Drives: Suitable when high torque is needed to drive rotation, especially in applications like crane slewing or solar tracker movement. The integrated gearing provides mechanical advantage for torque amplification.

(2) Speed and Precision

Slewing Bearings: Rotational speed and precision depend on the external drive system. They are best for applications where speed is moderate and precision requirements are not extreme.

Slew Drives: Offer controlled speed and high positional accuracy due to built-in reduction gears and motors. They are preferred for tasks requiring precise angular movement, such as in antenna pointing.

(3) Working Environment

Slewing Bearings: Can be sealed and coated for harsh environments (e.g., marine, mining). However, external drive components may need additional protection.

Slew Drives: Often designed as enclosed units with IP ratings for dust and water resistance. This makes them robust for outdoor or demanding conditions.

(4) Inspection and Maintenance

Slewing Bearings: Require periodic lubrication, wear inspection, and alignment checks. Maintenance is relatively straightforward but must be consistent.

Slew Drives: Need maintenance for gears, motors, and bearings. While more complex, many modern slew drives feature sealed-for-life designs or easy-access points for servicing.

(5) Cost-Effectiveness

Slewing Bearings: Generally more economical upfront, but total system cost may increase when adding separate drive components.

Slew Drives: Higher initial cost due to integrated technology, but they can reduce overall system complexity, installation time, and long-term maintenance expenses.

Solutions for Slewing Bearings and Slew Drives

At LyraDrive, we specialize in providing high-quality slewing bearings and slew drives tailored to your specific needs. With over 20 years of industry experience, we understand the nuances of rotational mechanics and offer solutions that enhance performance, reliability, and efficiency.

Our Expertise and Services:

Custom Design: We engineer slewing bearings and slew drives to match your exact load, speed, environmental, and spatial requirements.

Comprehensive Inventory: We maintain a vast stock of standard and specialized components, ensuring quick delivery and reduced downtime.

Technical Support: Our team offers end-to-end assistance—from selection and installation to maintenance and troubleshooting.

Quality Assurance: All our products undergo rigorous testing to meet international standards for durability and safety.

Why Choose LyraDrive?

Whether you are designing a new rotating system or upgrading existing machinery, LyraDrive provides the expertise to help you choose between slewing bearings and slew drives. We consider your application holistically, balancing factors like load capacity, precision, environmental conditions, and budget. Our solutions are deployed across industries, including construction, renewable energy, aerospace, and industrial automation.

Contact Us

For more information on slewing bearings, slew drives, or custom rotational solutions, reach out to LyraDrive today. Let us help you achieve seamless and reliable rotation in your projects.

Conclusion

Slewing bearings and slew drives are both vital to the world of rotational mechanics, but they serve different purposes. Slewing bearings are the backbone for load support in rotating structures, while slew drives are comprehensive systems that drive and control rotation. Understanding their differences—from function and components to application scenarios—is essential for selecting the right solution. By considering factors such as load, speed, environment, maintenance, and cost, engineers can make informed decisions that enhance system performance and longevity. With partners like LyraDrive, accessing tailored, high-quality rotational components becomes a straightforward path to engineering success