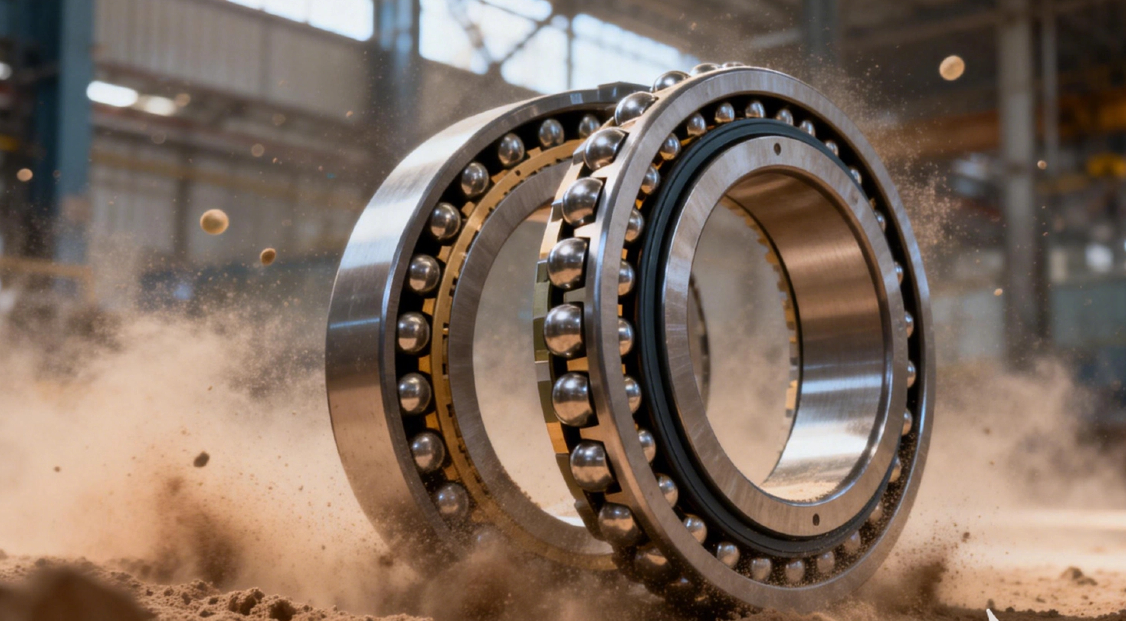

Sealed Slewing Bearing for Dusty Environment

What Is Slew Bearing?

Slewing bearings are critical components in many machines, from construction equipment to industrial machinery, enabling smooth rotation while supporting heavy loads. However, when used in dusty environments—such as construction sites, mines, or desert operatons—standard slewing bearings often struggle with dust intrusion, which can cause wear, corrosion, and premature failure. Sealed slewing bearings designed for dusty conditions address these challenges with specialized features, making them distinct from those for general environments. Below, we explore their key traits, how to select them, and the essential installation requirements.

Key Features of Sealed Slewing Bearings in Dusty Environments

The key features of sealed slewing bearings designed for dusty environments are summarized as follows:

(1) Enhanced Sealing Systems:

Equipped with multi-layered or heavy-duty seals (e.g., double-lip seals, labyrinth seals, or combination seals with dust shields), forming a tight barrier to block fine dust, sand, and debris from entering the bearing's rolling elements and raceways.

(2) Robust Material & Coating:

Adopts harder raceway materials (e.g., high-carbon hardened steel) and protective coatings (zinc, chrome, or ceramic) to resist abrasion caused by dust particles, reducing scratches and wear.

(3) Superior Grease Retention:

Features larger grease reservoirs and specialized grease channels to retain lubricant effectively—grease acts as an additional dust barrier. It resists contamination, avoiding reduced lubrication efficiency from dust-grease mixing.

(4) Reinforced Housing & Sealing Interfaces:

The outer housing and sealing connections are reinforced to prevent deformation or gaps, eliminating potential entry points for dust that standard bearings may have.

(5) Contamination Resistance:

Integrates design elements (seals, grease retention, material hardness) to comprehensively resist dust intrusion, ensuring stable performance and extending service life in harsh dusty conditions.

These features directly address the core challenge of dust intrusion, distinguishing them from standard bearings and making them reliable for applications like construction sites, mines, or desert operations.

How to Select Sealed Slewing Bearings for Dusty Environments?

Choosing the right sealed slewing bearing for a dusty environment requires considering both the environmental conditions and the application's demands. Follow these practical guidelines:

(1) Assess the Dust Type and Concentration:

First, identify the type of dust (e.g., fine sand, construction debris, industrial powder) and its concentration. For extremely dusty settings (e.g., desert mining), opt for bearings with multi-layer labyrinth seals or combination seals, as they offer superior protection against fine particles. For moderate dust levels (e.g., urban construction sites), double-lip seals may be sufficient.

(2) Prioritize Sealing Quality:

Evaluate the seal design and material. High-quality seals made of nitrile rubber (NBR), fluororubber (FKM), or polyurethane (PU) are more resistant to wear and temperature changes. Ensure the seal is tightly fitted to the bearing’s inner and outer rings with no gaps.

(3) Consider Load and Rotation Speed:

The bearing must handle the application’s radial, axial, and tilting loads. Dusty environments can increase friction, so select a bearing with a load capacity slightly higher than required. Also, check the maximum rotation speed—some heavy-duty seals may limit speed, so balance sealing performance with operational needs.

(4) Look for Grease Compatibility:

Choose a bearing compatible with high-temperature or heavy-duty grease, as dusty conditions require lubricants that resist breakdown and retain their protective properties. Some manufacturers offer pre-lubricated bearings with dust-resistant grease, which simplifies maintenance.

(5) Check Material and Coating Options:

For abrasive dust (e.g., sand), select bearings with hardened raceways and wear-resistant coatings. Zinc or chrome coatings protect against corrosion, while ceramic coatings offer extreme abrasion resistance. Avoid standard steel bearings in highly abrasive dust environments.

(6) Verify Manufacturer's Specifications:

Review the manufacturer’s data sheet for dust protection ratings (e.g., IP ratings) and service life estimates in dusty conditions. Reputable manufacturers often test their bearings in simulated dusty environments, so look for performance certifications or testimonials from similar applications.

How to Install Requirements for Sealed Slewing Bearings in Dusty Environments?

Proper installation is crucial to ensure the sealed slewing bearing performs as intended in dusty conditions. Even the best seal design will fail if installed incorrectly. Follow these steps and sub-guidelines:

(1) Prepare a Clean Installation Area

Before installation, clear the work area of dust, debris, and loose particles. Use a brush, vacuum, or compressed air (with low pressure to avoid spreading dust) to clean the mounting surface, bolts, and any adjacent components. A dirty installation area can introduce dust into the bearing during assembly, compromising the seal's effectiveness.

(2) Inspect and Clean Bearing Components

Examine the bearing for any damage (e.g., scratches on seals, dents on raceways) before installation. Wipe the bearing’s outer and inner rings with a clean, lint-free cloth—do not use harsh solvents, as they may damage the seals. Ensure the mounting surface (on the machine frame or rotating structure) is flat, smooth, and free of rust or burrs.

(3) Use Proper Mounting Techniques

Align the Bearing Correctly:

Misalignment can create gaps between the seal and the bearing rings, allowing dust entry. Use a level or alignment tool to ensure the bearing is mounted straight (no tilting or offset). Follow the manufacturer’s guidelines for maximum allowable misalignment (typically 0.1–0.3 mm).

Tighten Bolts Uniformly:

Use the recommended torque for mounting bolts, and tighten them in a crisscross pattern to distribute pressure evenly. Over-tightening can deform the bearing housing or seal, while under-tightening leaves gaps. Check bolt tightness again after the first few hours of operation, as vibration may loosen them.

(4) Protect Seals During Installation

Avoid using tools that could damage the seals (e.g., prizing tools, sharp objects). If pressing the bearing into place, use a sleeve or adapter that contacts the bearing’s raceway (not the seal or housing). Ensure that the seal’s lip is facing the direction of dust intrusion (e.g., outward for external dust) to maximize protection.

(5) Apply Grease Correctly

If the bearing is not pre-lubricated, apply the recommended dust-resistant grease evenly to the rolling elements and raceways. Fill the grease channels (if present) but do not over-grease—excess grease can trap dust and increase friction. Leave a small gap for grease expansion during operation.

(6) Perform Post-Installation Checks

After installation, rotate the bearing manually to ensure smooth movement (no binding or noise). Inspect the seal for any signs of damage or misalignment. Run the machine at low speed for a short period, then stop and check for dust accumulation around the seal. If dust is present, recheck the installation or replace the seal if necessary.

(7) Perform Post-Installation Checks

After installation, rotate the bearing manually to ensure smooth movement (no binding or noise). Inspect the seal for any signs of damage or misalignment. Run the machine at low speed for a short period, then stop and check for dust accumulation around the seal. If dust is present, recheck the installation or replace the seal if necessary.

Professional Slew Bearing Manufacturers: Your Trusted Partner for Dusty Environment Solutions

As a professional custom service provider of slewing drives and slewing bearings, Lyra Drive is dedicated to delivering superior, specialized equipment tailored for dusty environments. We understand the unique challenges posed by dust, sand, and debris in industrial and construction applications—and our engineering team combines extensive expertise with advanced manufacturing techniques to create products that excel in harsh conditions.

Beyond high-performance sealed slewing bearings, we offer customized professional solutions tailored to your specific application needs: from selecting the optimal seal design and material coatings to providing installation guidance and maintenance support. Whether you operate in mines, construction sites, desert operations, or other dusty settings, Lyra Drive ensures reliable, long-lasting performance that minimizes downtime and maximizes efficiency. Partner with us for a seamless, expert-driven approach to your slewing bearing needs in dusty environments.