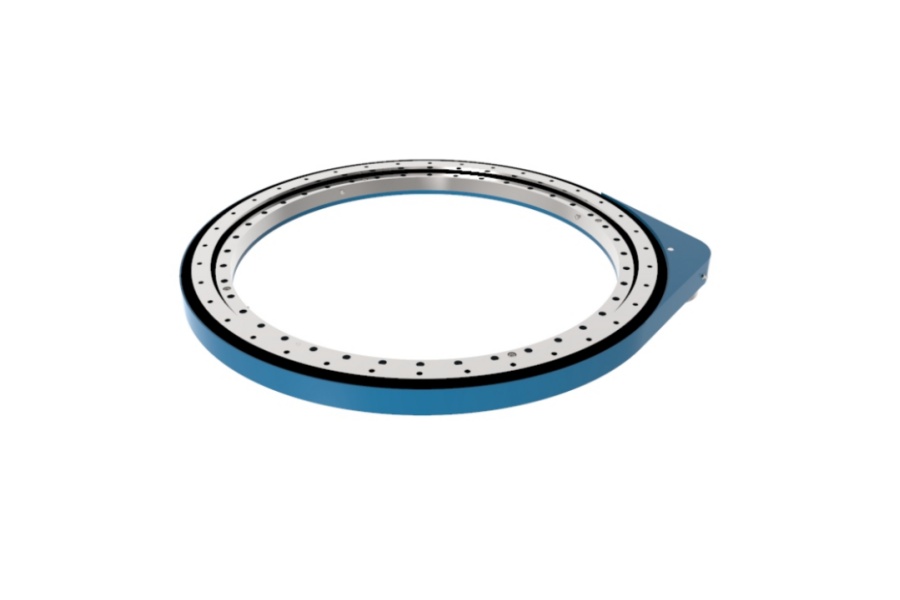

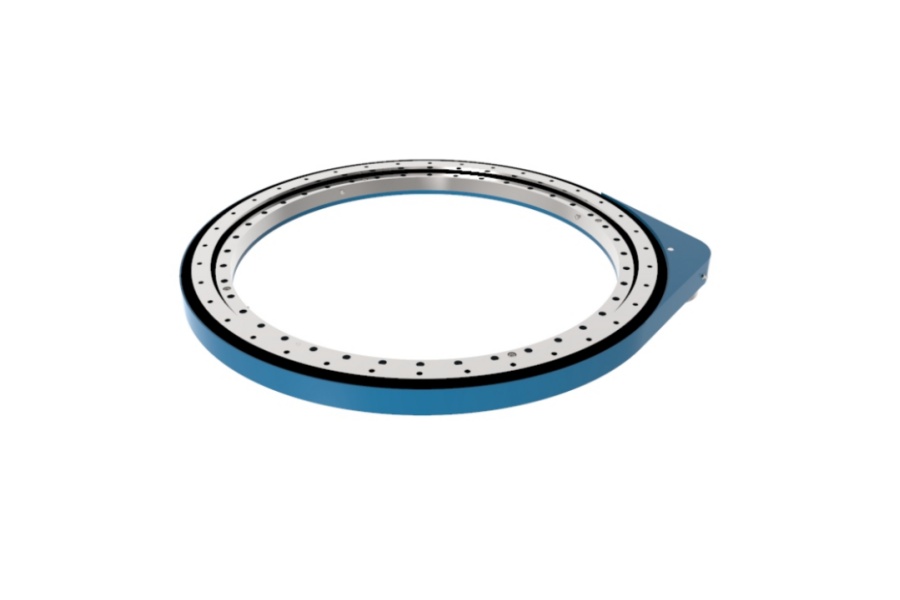

Medium Duty Gear Slewing Drive SP-M 0841 Powering Precision Rotation

What is Medium Duty Gear Slewing Drive SP-M 0841

Medium Duty Gear Slewing Drive SP-M 0841 represents a high-performance class of gear slewing drives designed for applications requiring significant torque, controlled speed, and precise positioning. It is fundamentally an integrated assembly comprising a precision slewing bearing with integral gearing (the wheel gear) and a mating pinion gear, all housed within a rigid, sealed structure. The core of this unit is its specifically engineered slewing bearing, meticulously designed to handle combined axial, radial, and moment loads simultaneously. Featuring a module of 6 mm, a wheel gear with 156 teeth (Z2), and a pinion gear with 15 teeth (Z1), it achieves a transmission ratio of 10.4:1 (i). This design translates input power, whether from an electric motor or hydraulic source, into powerful, smooth, and controlled rotational output. The unit is pre-assembled and precision-aligned, ensuring optimal gear meshing and structural integrity right out of the box, drastically reducing installation complexity compared to sourcing and assembling separate components like traditional slew bearings and external gearboxes.

Impact of Moment of Inertia on Slewing Drive Performance

Moment of Inertia (MOI) is a critical factor influencing the dynamic performance of any rotating system, including slewing drives like the SP-M 0841. MOI quantifies an object's resistance to changes in its rotational speed – essentially, how difficult it is to start rotating, stop rotating, or change the speed of rotation. In slewing drive applications, the MOI encompasses the drive unit itself plus the entire load it is rotating (e.g., a platform, boom, or antenna dish). A high MOI load demands significantly more torque from the drive system to achieve acceleration or deceleration compared to a low MOI load. For the SP-M 0841, with its substantial maximum drive torque capacity of 19,100 Nm (Md max), it is inherently capable of handling loads with considerable inertia. However, understanding the load's MOI remains crucial. High MOI can lead to slower acceleration/deceleration times, potential overshoot during positioning if control systems aren't tuned correctly, increased stress on gear teeth during dynamic events, and higher energy consumption, especially in applications requiring frequent starts and stops. The SP-M 0841's robust gear design and optimized internal structure help manage these inertial forces effectively, contributing to smoother operation and enhanced longevity under demanding dynamic conditions common in automation and heavy machinery.

Energy Efficiency Ratio of the SP-M 0841

The Medium Duty Gear Slewing Drive SP-M 0841 is engineered for operational efficiency, translating into a favorable energy efficiency ratio for its class. This efficiency stems from several key design aspects. Firstly, the precision manufacturing of its internal helical or spur gears ensures optimal tooth contact and minimal sliding friction, reducing mechanical losses during power transmission. Secondly, the use of high-quality, low-friction bearings within the slewing ring assembly minimizes rotational resistance. The unit's high torque density (delivering up to 19,100 Nm from a compact package) means less input power is required to achieve the necessary output torque compared to bulkier or less optimized designs. Furthermore, its IP65-rated full-seal design not only protects internal components but also retains lubrication effectively, maintaining consistent low-friction operation over extended periods and reducing the energy losses associated with friction from contamination. The flexibility in power source – accepting input from either highly efficient electric motors or hydraulic systems – allows system designers to choose the most energy-appropriate prime mover for the specific application context. While absolute efficiency figures depend heavily on the attached prime mover and operating conditions, the SP-M 0841's design prioritizes minimizing internal power losses, contributing directly to lower overall system energy consumption and operational costs over its lifespan.

Key Features of the SP-M 0841 Slewing Drive

The SP-M 0841 distinguishes itself in the medium-duty segment through a combination of powerful performance and practical engineering:

High Torque Capacity: Delivers a maximum drive torque (Md max) of 19,100 Nm and a nominal drive torque (Md nom) of 14,850 Nm, enabling it to handle significant rotational loads.

Robust Load Handling: Engineered for substantial static loads (C0 rad: 503 kN radial, C0 ax: 1,195 kN axial) and dynamic loads (C rad: 198 kN radial, C ax: 215 kN axial), ensuring stability under demanding conditions.

Operational Speed: Capable of slewing speeds up to 20 RPM, meeting the requirements for high-speed industrial automation tasks.

Integrated & Sealed Unit Design: The fully enclosed housing provides an IP65 protection rating, sealing out dust, dirt, and moisture while retaining lubrication. This eliminates the common problem of pinion-to-ring-gear backlash adjustment inherent in traditional slew bearing setups.

Precision Gearing: Features a 6 mm module gear system (Z1=15, Z2=156) with a ratio of 10.4:1, ensuring smooth, precise, and reliable motion transfer.

Power Source Flexibility: Compatible with both electric motors and hydraulic motors, offering adaptability to diverse application environments and power systems.

Simplified Installation & Maintenance: The pre-assembled, unitized design significantly reduces installation complexity and time. Sealed-for-life lubrication in many applications drastically extends maintenance intervals and lowers lifetime costs.

High Holding Capacity: Features a maximum holding torque (MH) of 19,100 Nm, providing secure positioning even when powered off.

Interchangeability: Designed to be interchangeable with the IMO model SP-M 0841, offering flexibility in sourcing.

Optimized Weight: Weighing 149 kg, it offers an excellent strength-to-weight ratio for its performance class.

Versatile Applications of the SP-M 0841

The combination of power, speed, precision, and ruggedness makes the Medium Duty Gear Slewing Drive SP-M 0841 suitable for a vast array of industrial applications requiring reliable rotation:

Automated Machinery: Robotic welding arms, material handling turntables, indexing tables, pallet changers, and assembly line positioning systems benefit from its precision and speed.

Construction & Earthmoving Equipment: Found in crane jib rotation, compact loader attachments, drilling rig positioning units, and concrete pump line rotation.

Material Handling: Powers rotating sections of conveyor systems, heavy-duty industrial positioners for welding, large bin tippers, and automated storage/retrieval system rotators.

Renewable Energy: Used for pitch and yaw control mechanisms in smaller wind turbines or solar tracking systems requiring robust performance.

Heavy Transport & Logistics: Enables rotation in specialized trailers, heavy-duty turntables for vehicle positioning, and container handling equipment.

Defense & Aerospace: Applicable in radar platform rotation, missile launcher positioning, and ground support equipment requiring precise movement.

Agricultural Machinery: Powers rotating elements in large sprayers, harvesting equipment, and irrigation systems.

Stage & Entertainment: Drives the rotation of lighting rigs, video screens, and performance platforms demanding smooth and reliable motion.

Essentially, any application needing robust, precise, and relatively high-speed rotation under medium-duty loads is a potential fit for the SP-M 0841.

Factors Influencing SP-M 0841 Pricing

The price of a Medium Duty Gear Slewing Drive SP-M 0841 is influenced by several interconnected factors:

Raw Material Costs: Fluctuations in the global prices of high-grade steel alloys used for gears, bearings, and housings directly impact manufacturing costs. Special coatings or treatments for enhanced wear or corrosion resistance also add cost.

Manufacturing Precision & Complexity: The high level of precision required in gear cutting, heat treatment (carburizing, hardening, grinding), bearing raceway machining, and final assembly demands sophisticated machinery and skilled labor, contributing significantly to the unit cost. Tighter tolerances mean higher costs.

Scale of Production: Economies of scale apply. Larger order quantities generally result in a lower per-unit cost due to optimized material purchasing and production line efficiency.

Customization: While the SP-M 0841 is a standard model, requests for modifications (special seals, lubrication, mounting flange configurations, surface treatments, specific backlash requirements, or unique input shaft/spline designs) add engineering time and production complexity, increasing the price.

Quality Assurance & Testing: Rigorous quality control procedures, including material certification, dimensional checks, gear profile testing, and potentially functional load testing, are essential for reliability but add to the overall cost.

Supply Chain & Logistics: Costs associated with sourcing components, transportation of raw materials and finished goods, warehousing, and international shipping (including tariffs) all factor into the final price.

Brand Value & Support: Reputable manufacturers like LYRADRIVE invest in engineering expertise, technical support, warranty services, and established distribution networks, aspects reflected in the product's value proposition.

Market Demand: General industrial demand and specific sector booms can influence pricing dynamics.

Supplier of the SP-M 0841: LYRADRIVE

LYRADRIVE is a recognized supplier and specialist in motion control solutions, offering high-performance slewing drives like the SP-M 0841. They focus on providing robust, reliable, and efficient rotational drive systems for demanding industrial applications. LYRADRIVE leverages engineering expertise to deliver products meeting stringent quality standards, ensuring the SP-M 0841 performs reliably in the diverse applications it serves. Their commitment encompasses not only the product itself but also supporting customers with technical knowledge for optimal integration and performance. Choosing LYRADRIVE means sourcing the SP-M 0841 from a provider dedicated to advanced motion technology and customer satisfaction in the industrial drive sector.