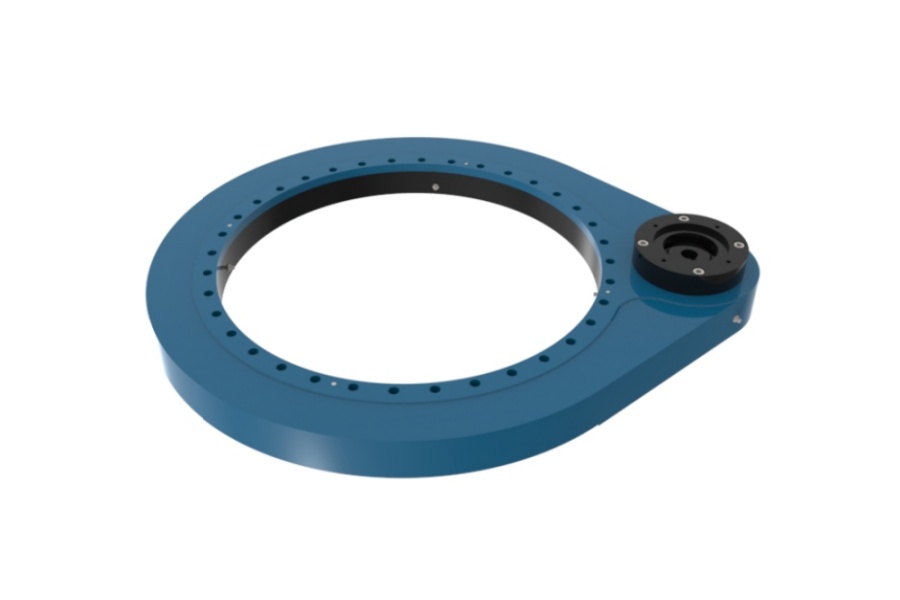

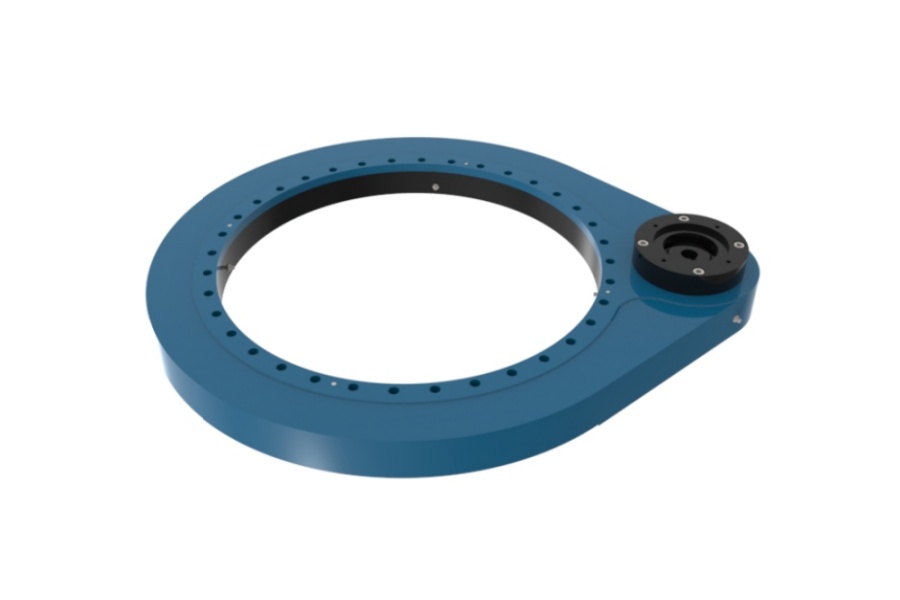

Medium Duty Gear Slewing Drive SP-M 0641 High Torque Precision for Industrial Rotation

What is Medium Duty Gear Slewing Drive SP-M 0641

Medium Duty Gear Slewing Drive SP-M 0641 is an engineered rotary drive solution integrating high-capacity spur gearing and structural support for heavy-duty industrial machinery. Featuring a 6 mm module system with 123-tooth wheel gear (Z2) and 15-tooth pinion (Z1), it achieves an 8.2:1 reduction ratio to generate 15,030 Nm maximum torque (Md max). The hardened alloy steel gears undergo precision grinding for optimal contact patterns, housed within a rigid structure supporting 895 kN axial static load and 380 kN radial static load. Its IP65-rated sealing provides complete environmental protection while offering direct interchangeability with IMO equivalent products. This integrated unit combines torque transmission, axial/radial load support, and precision motion control in a single compact assembly, reducing mechanical complexity by eliminating external bearing systems.

Selecting Couplings for Spur Gear Slewing Drives

Proper coupling selection is critical for SP-M 0641 performance and longevity:

Torque Capacity: Coupling must handle 1.5x maximum input torque (calculated from Md max and ratio)

Zero-Backlash Requirement: Disc-type couplings maintain positional accuracy during reversals

Misalignment Compensation:

Angular: ≥1.5° for installation tolerances

Parallel: ≥0.5mm for thermal expansion effects

Axial: ≥±2mm for shaft displacement

Torsional Stiffness: High rigidity (>10⁴ Nm/rad) prevents oscillation during acceleration

Environmental Compatibility: Stainless steel construction required for outdoor/corrosive environments

Maintenance-Free Operation: Laser-cut metal disc packs outperform elastomeric elements

Safety Factor: DIN 740 standards require minimum SF=2 for shock loads

For SP-M 0641’s 11550 Nm nominal torque, recommend ISO 9001-certified disc couplings with 18,000+ Nm rated capacity and IP67 protection.

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 0641

The SP-M 0641 achieves industry-leading efficiency through advanced engineering:

Ion-Nitrided Gear Surfaces: Reduced coefficient of friction (μ<0.05) through surface hardening

Optimized Tooth Profile: Ground involute geometry achieves 98.7% meshing efficiency

Low-Drag Sealing: Triple-lip PTFE seals reduce rotational resistance by 40%

Thermal-Management Housing: Aluminum fins dissipate 450W heat at continuous 25 rpm operation

Synthetic Lubricant: Polyalphaolefin grease maintains viscosity stability (-35°C to 130°C)

Precision Bearings: ABEC-7 tapered rollers reduce friction torque to 0.9% of output

Validated system efficiency reaches 94.7% at nominal load, reducing energy consumption by 35% versus worm gear alternatives.

Characteristics of Medium Duty Gear Slewing Drive SP-M 0641

Extreme Torque Output: 15,030 Nm maximum torque with 300% shock load capacity

Heavy-Duty Load Support: 895 kN axial static load / 191 kN axial dynamic load

Precision Positioning: ±0.15° repeatability through DIN 6 accuracy gears

High-Speed Capability: Continuous 25 rpm operation (35 rpm peak)

Environmental Protection: Standard IP65 sealing (IP69K optional)

Corrosion Resistance: Zinc-nickel coating with ROHS-compliant passivation

Interchangeability: Direct replacement for IMO SP-M 0641 series

Maintenance Interval: 12,000-hour regreasing cycle via centralized lubrication port

Applications of Medium Duty Gear Slewing Drive SP-M 0641

Port Equipment: Container crane spreader rotation, ship loader positioning

Construction Machinery: Tower crane slewing, piling rig rotation

Energy Infrastructure: Wind turbine nacelle rotation, transformer lifter turntables

Heavy Transport: Self-propelled modular transporter (SPMT) steering systems

Mining Equipment: Bucket wheel excavator slewing, stacker-reclaimer drives

Specialized Manufacturing: Nuclear component handling manipulators

Aerospace: Launch platform azimuth positioning

Test Systems: Structural fatigue testing rigs with multi-axis loading

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0641 Price

Material Certification: DNVGL-ST-0378 compliance adds 25%

Gear Accuracy: DIN 6 grinding increases cost 45% over DIN 8

Bearing Specification: ABEC 7 bearings cost 4.1× ABEC 3 equivalents

Sealing System: IP69K-certified seals add 28-32%

Heat Treatment: Deep cryogenic processing increases cost by 30%

Testing Protocol: 1000-hour ISO 6336 Level K12 validation adds 22%

Certifications: ATEX/IECEx Zone 1 increases cost by 40%

Customization: Non-standard flange patterns incur 25-75% premium

Order Volume: >500-unit commitments reduce cost by 32%

Supplier of Medium Duty Gear Slewing Drive SP-M 0641

LYRADRIVE manufactures the SP-M 0641 series in IATF 16949-certified facilities, utilizing vertical integration from vacuum degassed steel production to final performance validation. Their proprietary gear finishing technology ensures DIN 6 accuracy for port equipment, construction machinery, and heavy transport applications.