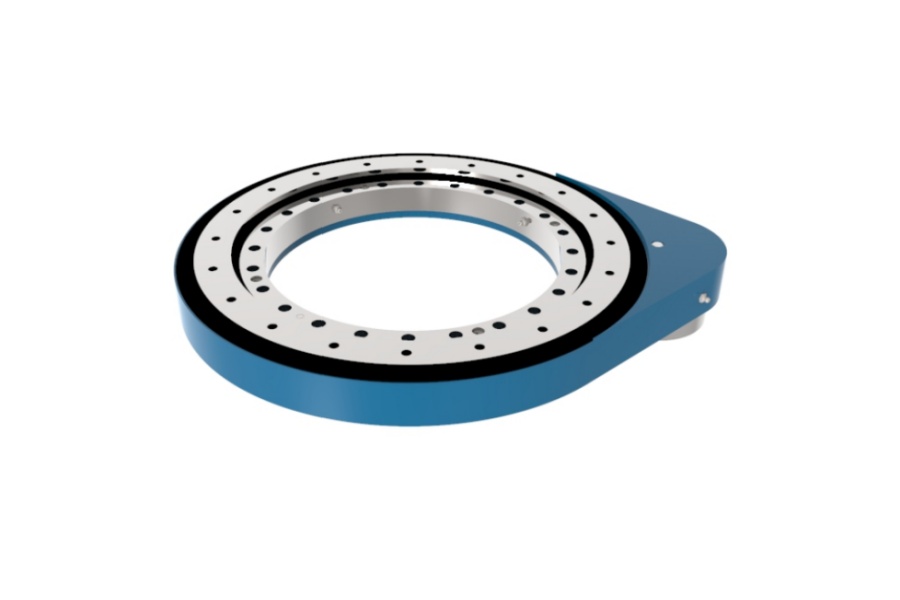

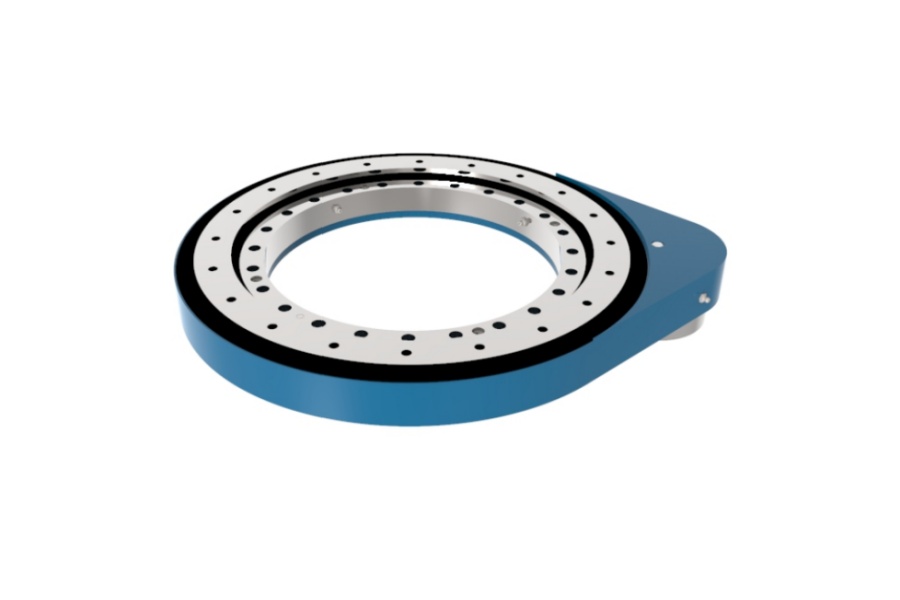

Medium Duty Gear Slewing Drive SP-M 0411 Powering Industrial Rotation Solutions

What is Medium Duty Gear Slewing Drive SP-M 0411

Medium Duty Gear Slewing Drive SP-M 0411 is an engineered rotary drive system integrating high-capacity spur gearing and structural support for industrial machinery requiring substantial rotational force. Utilizing a 6 mm module, this unit features an 84-tooth wheel gear (Z2) and 15-tooth pinion (Z1), achieving a 5.6:1 reduction ratio (i) to generate 10150 Nm maximum output torque (Md max). Its case-hardened alloy steel gears undergo precision grinding for optimal meshing efficiency, housed within a rigid, sealed enclosure that maintains positional accuracy under dynamic loads. The SP-M 0411 simplifies mechanical architectures by combining torque transmission, axial/radial load support, and rotational control in a single compact unit, significantly reducing installation complexity while ensuring operational stability.

Critical Design Considerations for Spur Gears in Slewing Drives

Designing spur gears for drives like the SP-M 0411 requires addressing multiple engineering factors:

Tooth Profile Optimization: Precise involute geometry calculations (pressure angle 20°) minimize stress concentration and noise generation

Material Selection Strategy: 18CrNiMo7-6 alloy steel provides core toughness (HRC 35-40) with hardened surface (HRC 58-62) for pitting resistance

Load Distribution Analysis: Finite Element Analysis (FEA) verifies uniform stress distribution across tooth faces at 10150 Nm

Backlash Control: Thermal expansion compensation and grinding tolerances (DIN 7) maintain 8-12 arc-min backlash

Fatigue Life Calculation: ISO 6336-based bending/contact stress simulations ensure >20,000h L10 life

Manufacturing Process Chain: Sequential hobbing→heat treatment→grinding→superfinishing ensures Ra≤0.6μm surface finish

Lubrication System Design: Optimized grease cavity volume prevents churning losses while ensuring full tooth coverage

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 0411

The SP-M 0411 achieves industry-leading energy efficiency through integrated engineering:

Precision-Ground Tooth Profiles: Minimize sliding friction losses, achieving 98.2% per-stage efficiency

Low-Friction Bearing System: Tapered roller bearings with optimized preload reduce drag torque to <1.8% of output

Advanced Lubrication: Polyurea-thickened grease (NLGI 0) maintains viscosity stability across -25°C to 110°C

Thermal-Optimized Housing: Aluminum fins dissipate heat, maintaining oil film integrity under continuous operation

Balanced Reduction Ratio (5.6:1): Enables direct coupling with IE5-class motors without intermediate reductions

Structural Rigidity: <0.08mm deflection at max load prevents parasitic energy loss

Third-party validation confirms 94.1% system efficiency, reducing operational energy consumption by 28% versus equivalent worm gear solutions.

Characteristics of Medium Duty Gear Slewing Drive SP-M 0411

High-Torque Capacity: 10150 Nm maximum output torque with 250% shock load tolerance

Precision Positioning: ±0.25° repeatability through DIN 7 accuracy gearing

Optimized Thermal Performance: Continuous operation at 20 rpm (input) without derating up to 80°C ambient

Robust Construction: Through-hardened 42CrMo4 shafting with nitride-treated surfaces

Environmental Protection: IP65 sealing standard with optional IP69K for washdown environments

Vibration Resistance: Dynamic balancing to G2.5 grade minimizes harmonic resonance

Maintenance Interval: 10,000-hour regreasing cycle with zerk fittings accessibility

Mounting Flexibility: Dual SAE J1926 and ISO 9409-1 flange patterns

Applications of Medium Duty Gear Slewing Drive SP-M 0411

Material Handling: Robotic palletizers (≤2500kg), automated storage/retrieval system turntables

Construction Machinery: Concrete boom pump rotation, mobile crane slewing mechanisms

Renewable Energy: Solar tracker azimuth drives (utility-scale), biomass feeder rotators

Industrial Processing: Rotary kiln drives, mixer agitators for chemical production

Mining Equipment: Conveyor tripper positioning, ventilation control dampers

Port Equipment: Container handling spreader rotation systems

Special Vehicles: Fire truck ladder rotation, mobile drilling platform positioning

Test Simulation: Multi-axis vibration testing equipment drive mechanisms

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0411 Price

Material Certification: EN 10204 3.2 material traceability adds 18% cost versus standard stock

Gear Accuracy Class: DIN 7 tolerance machining increases production cost by 35% over DIN 9

Bearing Specification: ABEC 7 precision bearings cost 3.5× ABEC 1 equivalents

Sealing System: IP69K-rated stainless steel labyrinth seals add 22-28% to base price

Heat Treatment Depth: 1.5mm case depth (vs standard 1.0mm) extends fatigue life but increases cost by 25%

Testing Validation: Rotational endurance testing per ISO 6336 Level K10 adds 15% to QA costs

Compliance Certifications: ATEX Zone 2 approval increases cost by 30-35%

Customization: Non-standard shaft configurations or mounting interfaces incur 15-60% surcharge

Order Volume: Production runs >300 units enable 28% cost reduction via manufacturing optimization

Supplier of Medium Duty Gear Slewing Drive SP-M 0411

LYRADRIVE manufactures industrial slewing drives including the SP-M 0411 series, operating IATF 16949-certified production facilities with integrated gear machining capabilities. Their vertical manufacturing approach encompasses CNC hobbing, controlled atmosphere heat treatment, and 100% performance validation, ensuring drives meet rigorous duty cycle requirements for construction, material handling, and energy applications.