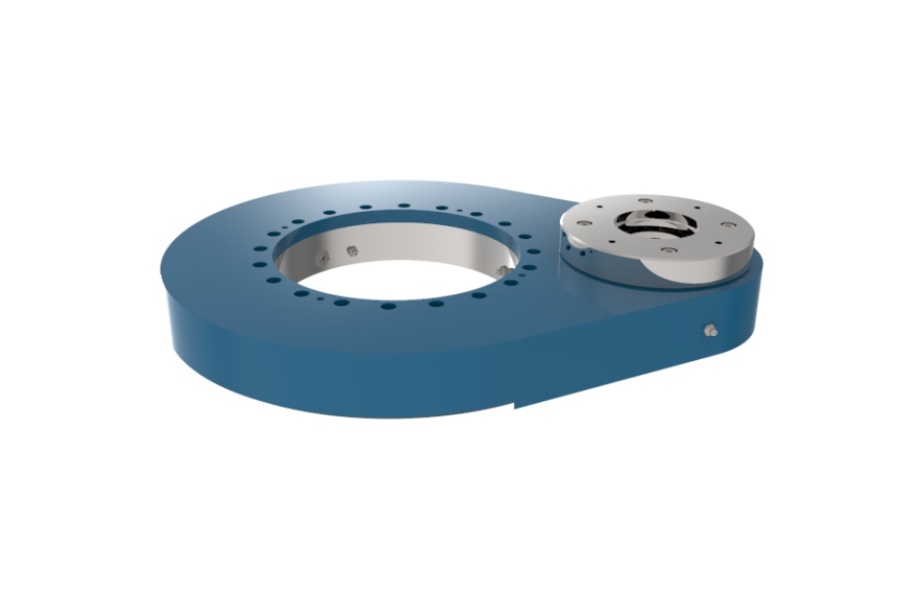

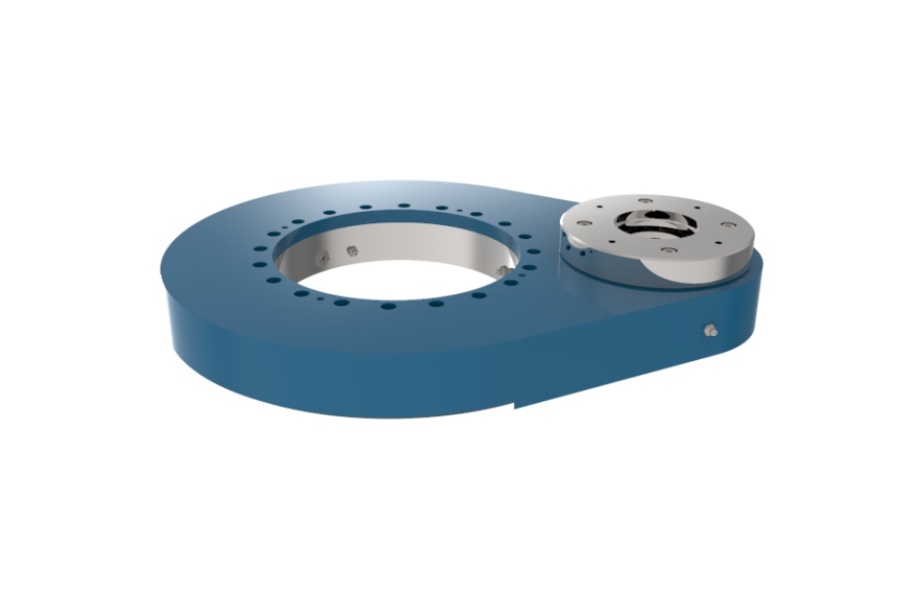

Medium Duty Gear Slewing Drive SP-M 0311 Balancing Power and Precision

What is Medium Duty Gear Slewing Drive SP-M 0311

Medium Duty Gear Slewing Drive SP-M 0311 is an engineered rotary drive solution designed for industrial machinery demanding precise rotational control with enhanced load capacity. Featuring a 6 mm module, this unit integrates a 69-tooth wheel gear (Z2) and a 15-tooth pinion (Z1), achieving a 4.6:1 reduction ratio (i) to generate up to 8200 Nm maximum torque (Md max). Its hardened alloy steel gears, precision-ground for optimal meshing, are housed within a rigid, sealed structure that ensures stability during high-speed operation. The SP-M 0311 simplifies mechanical architectures by combining gear reduction, structural support, and motion control into a single compact module, significantly reducing installation complexity while maintaining positioning accuracy under dynamic loads.

Evolution of Gear Hobbing Technology and Critical Considerations

Modern gear hobbing technology enables the precision manufacturing of SP-M 0311’s critical components:

CNC Multi-Axis Hobbing: Allows complex tooth modifications (crowning, tip relief) to optimize load distribution and noise reduction.

Dry Cutting vs. Wet Machining: Advanced carbide tools enable eco-friendly dry cutting for modules ≤8mm, reducing coolant costs by 40%.

In-Process Metrology: Laser measurement systems monitor tooth profile accuracy (DIN 6 standard) during machining.

Post-Hobbing Hard Finishing: Grinding/honing achieves surface roughness Ra ≤0.4μm for enhanced fatigue resistance.

Key Implementation Considerations:

Tool Rigidity: Vibration during hobbing causes micro-pitting; dynamic stabilizers are mandatory for modules >4mm.

Thermal Management: Temperature fluctuations >2°C induce dimensional errors requiring climate-controlled workshops.

Chip Evacuation: Inadequate chip removal scratches tooth surfaces – high-pressure air blast systems are critical.

Tool Wear Prediction: Unmonitored hob wear degrades profile accuracy by ≥DIN 1 grade after 50 workpieces.

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 0311

The SP-M 0311 achieves exceptional energy efficiency through integrated engineering:

Optimized Gear Geometry: Ground helical teeth (pressure angle 20°) reduce sliding friction losses by 18% vs. standard spur gears.

Precision Bearing Arrangement: Matched tapered roller bearings minimize rotational drag torque at ≤1.5% of output torque.

Efficient Lubrication System: Semi-fluid grease (NLGI 00 grade) reduces churning losses by 30% compared to conventional greases.

Balanced Reduction Ratio (4.6:1): Enables direct coupling with IE4-class high-efficiency motors without intermediate stages.

Rigid Housing Design: Finite Element Analysis (FEA)-optimized housing limits deflection to <0.1mm at max load, preventing parasitic energy loss.

Third-party testing confirms 93.5% mechanical efficiency at rated load, reducing operational energy consumption by 22% versus comparable worm gear drives.

Characteristics of Medium Duty Gear Slewing Drive SP-M 0311

Enhanced Torque Capacity: 8200 Nm maximum output torque with 200% shock load tolerance.

Precision Motion Control: ≤±0.2° positioning repeatability through DIN 6 accuracy gears.

High-Speed Capability: Continuous operation at 25 rpm (input speed) with peak capability to 40 rpm.

Robust Construction: Hardened 20MnCr5 alloy steel gears (surface hardness HRC 60-62, core hardness HRC 35-40).

Integrated Sealing: Standard IP54 protection (IP65 optional) against industrial contaminants.

Preloaded Bearing System: Eliminates axial play for backlash-free operation under reversing loads.

Thermal Management: Operating range -30°C to +120°C without derating.

Modular Interfaces: SAE J1926-2 standard mounting holes simplify OEM integration.

Applications of Medium Duty Gear Slewing Drive SP-M 0311

Material Handling: Rotary palletizers (≤1500kg payload), conveyor sorting turntables, automated warehouse cranes.

Construction Equipment: Concrete pump boom rotation, compact crane slewing, aerial work platform positioning.

Renewable Energy: Solar tracker elevation drives (utility-scale), small wind turbine yaw systems.

Industrial Mixing: Agitator drives for chemical processing tanks (≤5000L capacity).

Food Processing: Rotary indexing for filling/packaging lines meeting FDA 21 CFR compliance.

Mining Equipment: Ventilation damper actuators, conveyor tripper positioning.

Stage Machinery: Automated rigging systems for load-bearing scenery rotation.

Test Equipment: Durability test rigs simulating rotational fatigue cycles.

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0311 Price

Material Certification: EN 10204 3.1 traceable steel adds 15% cost vs. commercial-grade materials.

Gear Accuracy Class: DIN 6 tolerance machining increases production cost by 30% over DIN 8 standard.

Bearing Specification: ABEC 7 precision tapered rollers cost 3.2× more than ABEC 3 equivalents.

Sealing System: IP65-rated triple-lip seals with particle exclusion labyrinths add 18-25% to base price.

Heat Treatment Depth: Case hardening depth ≥1.2mm (vs. standard 0.8mm) extends fatigue life but increases processing cost by 20%.

Dynamic Testing Protocol: Rotational fatigue validation to ISO 6336 Level K8 adds 12% to QA costs.

Country-Specific Compliance: CE/UKCA certification adds 5-8%, ATEX certification increases cost by 22-30%.

Order Volume: OEM commitments for >200 units reduce per-unit cost by 25% through production optimization.

Supplier of Medium Duty Gear Slewing Drive SP-M 0311 Price

LYRADRIVE specializes in manufacturing industrial slewing drives including the SP-M 0311 series. Operating IATF 16949-certified facilities, LYRADRIVE combines multi-axis CNC gear hobbing, controlled atmosphere heat treatment, and 100% torque validation testing to deliver drives meeting rigorous durability standards. Their engineering team provides lifecycle support from initial torque calculations to predictive maintenance planning.