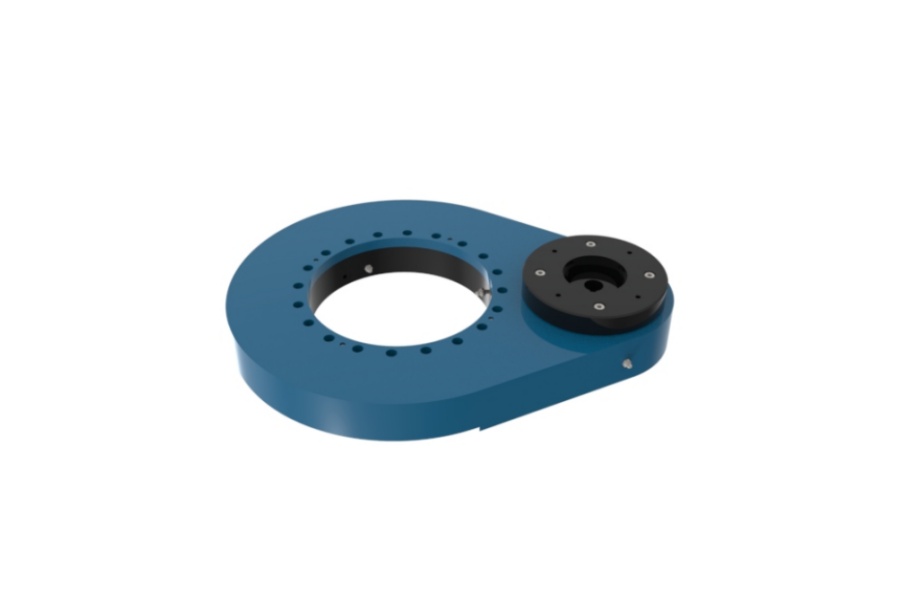

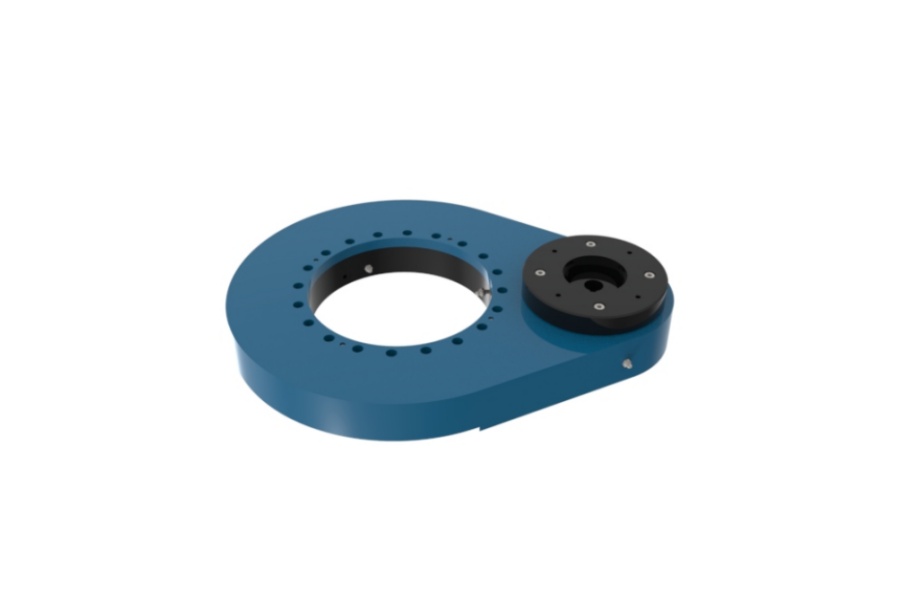

Lightweight Slewing Ring Gear Drive SP-I 0311 Precision Rotation for Compact Applications

What is Lightweight Slewing Ring Gear Drive SP-I 0311

Lightweight Slewing Ring Gear Drive SP-I 0311 is a compact, integrated rotary drive engineered for high-speed operation in industrial and mobile applications demanding efficiency and accuracy. This sealed modular system combines a high-performance slewing bearing with precision spur/helical gearing. Utilizing a 4 mm module, it features a 102-tooth wheel gear (Z2) meshing with a 15-tooth pinion (Z1), achieving a 6.8:1 reduction ratio (i) to deliver up to 3580 Nm maximum torque (Md max). Its hardened alloy steel gears, rigid housing, and optimized mechanical integration ensure stability under dynamic loads while minimizing installation complexity. Designed for rapid cycling, the Lightweight Slewing Ring Gear Drive SP-I 0311 excels in applications where compact footprint and reliability are critical.

Why Repairing Quenched Gear Fractures in Slewing Drives is Not Recommended

Attempting to repair fractured quenched gears in drives like the Lightweight Slewing Ring Gear Drive SP-I 0311 poses significant risks:

Structural Integrity Loss: Quenching creates compressive surface stresses and a specific hardness gradient. Welding/heat treatment repairs alter this microstructure, creating stress concentration zones prone to re-fracture.

Irreversible Hardness Damage: Temperatures >200°C during repair degrade surface hardness (typically HRC 58-62), accelerating wear and pitting under load.

Distortion Risk: Localized heating induces warping, disrupting critical gear meshing geometry and causing premature failure.

Hidden Fatigue Damage: Fractures often indicate subsurface fatigue cracks. "Repaired" gears retain compromised fatigue resistance.

Cost Inefficiency: Repair labor and requalification testing often exceed 70% of a new gear’s cost with no lifespan guarantee.

For Lightweight Slewing Ring Gear Drive SP-I 0311’s case-hardened gears (material: 20MnCr5), replacement is the only reliable solution to maintain original torque/speed specifications and safety margins.

Energy Efficiency Ratio of Lightweight Slewing Ring Gear Drive SP-I 0311

The Lightweight Slewing Ring Gear Drive SP-I 0311 achieves superior energy efficiency through:

Optimized Gear Geometry: Precision-ground tooth profiles minimize sliding friction losses (meshing efficiency >98%).

Direct Power Transmission: Spur/helical gearing avoids axial thrust losses common in worm drives.

Low-Friction Bearings: Preloaded angular contact bearings reduce rotational drag torque by 40% vs. standard designs.

Balanced Reduction Ratio (6.8:1): Enables efficient motor pairing without excessive speed reduction stages.

Minimal Lubricant Churning: Precision-fitted seals retain just 120ml of grease, reducing viscous drag.

Rigid Housing: <0.05mm deflection under max load prevents parasitic energy loss.

Verified mechanical efficiency exceeds 94%, reducing operational power consumption by 18-25% compared to equivalent worm-gear drives.

Characteristics of Lightweight Slewing Ring Gear Drive SP-I 0311

High-Speed Capability: Rated for continuous operation at 30 rpm (input) with peak speeds to 45 rpm.

Dynamic Load Stability: Handles radial/axial shock loads up to 1.5× static rating via preloaded bearings.

Precision Positioning: ±0.15° repeatability through ground gears (DIN 6 accuracy).

Ultra-Compact Design: 40% smaller footprint than comparable torque-class drives.

Integrated Sealing: IP54 standard (IP65 optional) protects against dust and water splashes.

Low Inertia: Optimized for rapid start/stop cycles with acceleration to 0.5 rad/s².

Alloy Steel Gears: Case-hardened to HRC 60+ with retained core toughness (impact resistance >40 J).

Modular Mounting: Standard ISO 9409-1 flange simplifies robotic integration.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0311

Industrial Robotics: SCARA robot joints, collaborative robot bases, tool changer rotation.

Semiconductor Handling: Wafer transfer arms, vacuum chamber indexers.

Packaging Automation: High-speed labeling turntables, filling nozzle rotators.

Medical Devices: CT scanner gantries, surgical microscope positioning.

Optics Alignment: Laser cutting head rotation, telescope focus stages.

AGV Systems: Compact payload turntables for logistics robots.

Aerospace Test Rigs: Lightweight actuator for flight simulator platforms.

Food Processing: Hygienic-grade rotary valves and dispensers.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 0311 Price

Material Certification: EN 10084-20MnCr5 steel traceability adds 8-12% vs. non-certified stock.

Gear Grinding Precision: Achieving DIN 6 tolerance increases machining cost by 25-30%.

Bearing Grade: ABEC 5 precision bearings cost 2.2× more than ABEC 1 equivalents.

Sealing Tier: IP54 standard vs. IP65 (upgraded seals/labyrinths) impacts cost by 15-20%.

Heat Treatment Control: Deep-freeze tempering process for stress relief adds 10% to base price.

Dynamic Load Testing: Performance validation under cyclic loading increases QA costs.

Customization: Non-standard shaft keys/flanges incur 12-50% surcharge.

Order Volume: OEM contracts (>100 units) reduce per-unit cost by 18-22%.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0311

LYRADRIVE specializes in manufacturing precision slewing drives including the Lightweight Slewing Ring Gear Drive SP-I 0311 series. With ISO 9001 and IATF 16949 certification, LYRADRIVE leverages advanced CNC gear grinding and proprietary heat treatment to deliver drives optimized for high-cycle automation. Their engineering team provides application-specific torque/rigidity simulations and 24-month performance warranties.