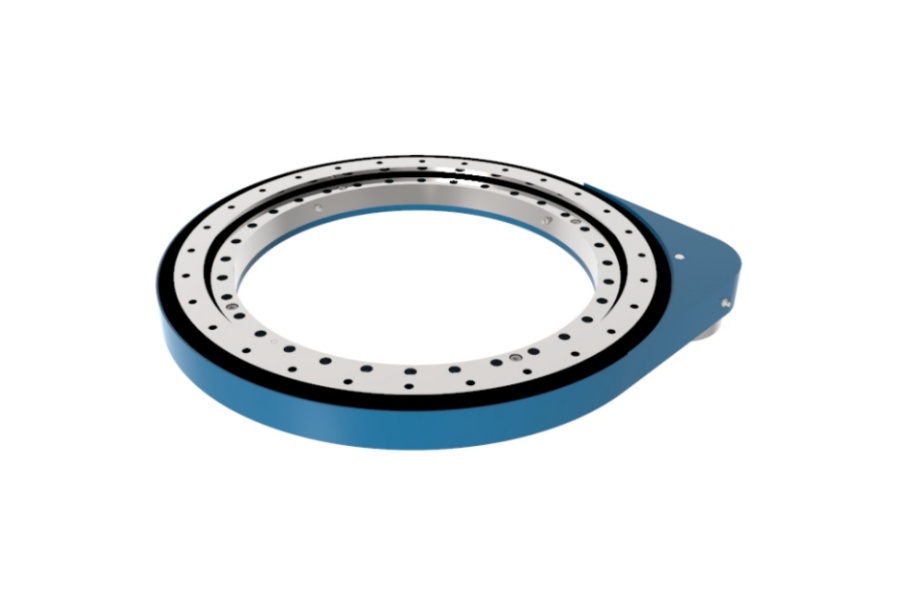

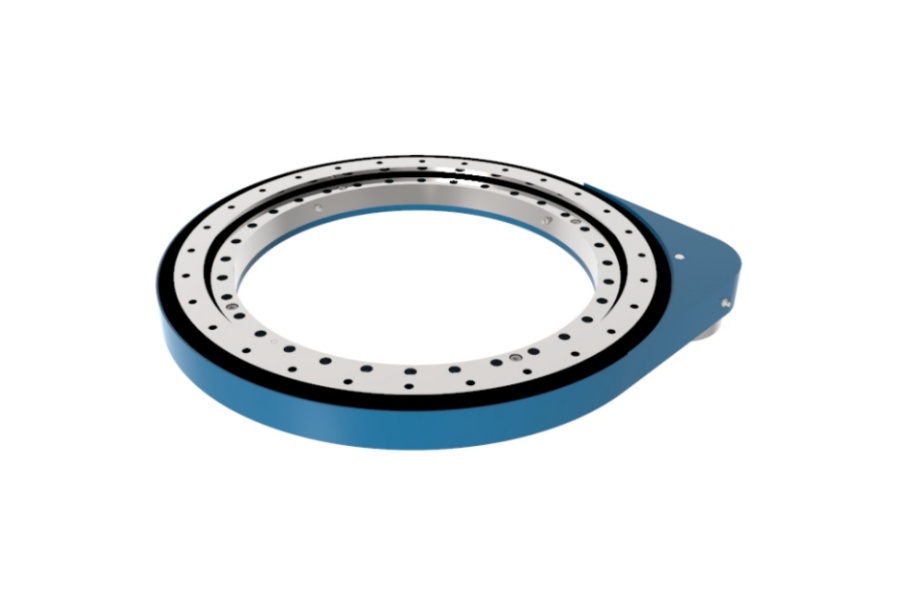

Lightweight Gear Slewing Drive SP-I 0541 Optimizing High-Speed Rotation

What is Lightweight Gear Slewing Drive SP-I 0541

Lightweight Gear Slewing Drive SP-I 0541 is an integrated, high-performance rotary drive unit specifically engineered for applications demanding high load capacity, rapid rotational speeds, and unwavering precision. This model features an integrated slewing bearing combined with a precise gear reduction system achieving a 10.4:1 ratio (i). Constructed with a 4 mm module, it utilizes a robust wheel gear with 156 teeth (Z2) meshing with a 15-tooth pinion gear (Z1). This configuration efficiently converts input rotation into substantial output torque, reaching a maximum of 5650 Newton meters (Md max), while maintaining excellent structural rigidity critical for stability under load. Designed for seamless integration into industrial machinery, its compact, modular design significantly simplifies mechanical systems, reduces installation complexity, and enhances long-term operational reliability. The unit is fully sealed to IP65 standards, providing comprehensive protection against dust ingress and water jets, ensuring dependable performance even in harsh industrial environments.

Analyzing Gear Safety Factor in Gear Slewing Drives

The gear safety factor (S.F.) is a paramount engineering calculation ensuring the long-term reliability and operational integrity of gear slewing drives like the SP-I 0541 under expected and peak load conditions. It represents the ratio between the gear material's inherent strength (its capacity to resist failure) and the actual maximum stress experienced during operation. A higher safety factor indicates a greater margin against potential failure modes such as tooth bending fatigue (breakage) or surface contact fatigue (pitting and spalling). For the SP-I 0541, designed for high loads and speeds, achieving an appropriate safety factor involves meticulous engineering:

Material Selection: Utilizing high-strength, case-hardened alloy steels significantly boosts the fatigue strength of both the pinion and wheel gear teeth.

Precision Manufacturing: Advanced grinding processes ensure accurate tooth profiles, optimal root fillets, and smooth surface finishes, minimizing stress concentrations that can initiate cracks.

Heat Treatment: Controlled hardening and tempering processes achieve the optimal balance of surface hardness for wear and pitting resistance and core toughness for impact resistance.

Load Analysis: Comprehensive calculations consider not only the nominal output torque (5650 Nm max) but also dynamic loads from acceleration/deceleration, shock loads, potential misalignment forces, and the influence of combined axial, radial, and moment loads on the integrated bearing.

Application Duty Cycle: The expected frequency and duration of peak loads versus average operating loads are critical factors. Continuous high-load operation requires a higher safety factor than intermittent use.

Lubrication & Contamination Control: Effective lubrication minimizes wear and friction-induced stress, while robust sealing (like IP65 in SP-I 0541) prevents abrasive contamination that accelerates surface fatigue. Adherence to standards like AGMA (American Gear Manufacturers Association) provides methodologies for calculating bending and contact safety factors. For critical applications like those served by the SP-I 0541, manufacturers target safety factors well above the theoretical minimum (often S.F. > 1.5 or higher for bending, and > 1.0 - 1.2 for contact stress) to account for real-world uncertainties and ensure a long, trouble-free service life under demanding conditions.

Energy Efficiency Ratio of Lightweight Gear Slewing Drive SP-I 0541

The Lightweight Gear Slewing Drive SP-I 0541 is engineered to achieve high operational efficiency, directly translating into a favorable energy consumption ratio. This efficiency minimizes power losses and contributes to lower overall energy costs for the machinery it powers. Key elements underpinning its energy-efficient performance include:

Precision Ground Gearing: The use of accurately ground tooth profiles on both the pinion and wheel gear ensures smooth meshing action, minimizing sliding friction and associated power losses. The optimized geometry promotes efficient power transfer.

High-Quality Bearing Integration: The integrated slewing bearing is selected and preloaded for low rotational friction. Efficient power transmission relies on minimizing losses within the bearing system.

Optimized Lubrication: The drive is filled with a high-performance, long-life grease specifically formulated for gear systems operating under high loads and speeds. This grease maintains low friction coefficients and protects against wear, sustaining efficiency over time.

Effective IP65 Sealing: While seals introduce slight drag, the IP65-rated seals on the SP-I 0541 are designed to balance effective protection against contamination with minimal friction. Preventing contamination ingress is crucial to maintaining lubricant integrity and preventing wear-induced efficiency losses.

Efficient Gear Ratio (10.4:1): This ratio allows the use of smaller, inherently more efficient electric motors to generate the required high output torque and speed at the drive's output. Reducing the motor size directly reduces the primary energy input requirement.

Rigid Construction: The high structural rigidity minimizes energy losses due to housing deflection under load, ensuring power is effectively transferred to the output rather than being absorbed by component flexing.

While a single definitive "efficiency ratio" figure encompassing all internal losses isn't typically published, well-engineered slewing drives like the SP-I 0541 achieve overall mechanical efficiencies typically in the range of 90-94% under standard operating conditions. This high efficiency means less energy is wasted as heat and lower power consumption is needed from the drive motor, leading to tangible operational cost savings and reduced environmental impact.

Characteristics of Lightweight Gear Slewing Drive SP-I 0541

The SP-I 0541 distinguishes itself through a suite of performance characteristics tailored for robust, high-speed industrial automation:

High Load Capacity & Torque Output: Engineered to deliver substantial output torque (5650 Nm max) while supporting significant axial, radial, and moment loads via its integrated slewing bearing, making it ideal for demanding applications.

High-Speed Operation: Specifically designed for smooth and reliable performance at elevated rotational speeds, enabling faster machine cycles and increased throughput compared to many standard slewing drives.

Exceptional Structural Rigidity: The integrated design and robust construction provide outstanding resistance to deformation under load, ensuring precise positioning and stable operation even during high-speed maneuvers or under heavy loads.

Precision Motion Control: Manufactured with high-precision ground gears and tight tolerances, enabling accurate angular positioning, smooth motion, and excellent repeatability essential for automated processes.

Compact & Lightweight Design: Despite its high power density, the unit features a space-saving, modular design that reduces overall system footprint and weight, simplifying integration into machinery.

High Reduction Ratio (10.4:1): Provides significant speed reduction and torque multiplication from a compact package, allowing efficient power transfer from the input motor.

IP65 Sealed Protection: The fully sealed housing offers superior defense against dust and water ingress, ensuring reliable operation and longevity in challenging industrial environments like washdown areas or dusty workshops.

Integrated Slewing Bearing: Combines the gear reduction and the rotary bearing into a single, pre-assembled unit, drastically simplifying design, installation, and maintenance.

Durability & Long Service Life: Utilizes high-strength materials, precision manufacturing, surface hardening, and quality lubrication to ensure extended operational life under continuous, demanding use.

Applications of Lightweight Gear Slewing Drive SP-I 0541

The combination of high load capacity, high-speed capability, precision, and compactness makes the SP-I 0541 exceptionally suited for a wide range of demanding industrial scenarios:

High-Speed Industrial Automation: Robotic arms (especially for base rotation or heavy tool handling), rapid indexing tables for machining or assembly, high-throughput palletizing/depalletizing systems, automated guided vehicle (AGV) turntables.

Packaging & Filling Lines: Rotary fillers for liquids or powders operating at high speeds, high-speed capping machines, labeling applicators for fast-moving lines, product orientation turntables requiring quick, precise positioning.

Material Handling Equipment: Rotary actuators for heavy grippers or manipulators, positioning drives for conveyor diverters, rotating platforms in automated storage and retrieval systems (AS/RS) handling substantial loads.

Machine Tool Automation: Rotary tool changers, heavy-duty fixture rotation for CNC machining centers, part positioning indexers requiring rigidity under cutting forces.

Process Machinery: Agitators or mixers requiring robust rotation under load, valve actuators for large process lines, rotating drums or barrels in manufacturing processes.

Test & Simulation Equipment: Heavy-duty rotary positioning stages for structural testing, fatigue testing rigs, environmental simulation tables requiring high torque and speed.

Specialized Machinery: Positioning drives for large medical imaging components (requiring smooth motion), stages for high-power laser processing, rotating platforms in entertainment/rigging (where speed and control are critical).

Factors Influencing Lightweight Gear Slewing Drive SP-I 0541 Price

The cost of the Lightweight Gear Slewing Drive SP-I 0541 is determined by a confluence of factors related to its design, materials, manufacturing, and features:

High-Strength Materials: The cost of the specialized alloy steels used for gears, shafts, housings, and the integrated slewing bearing races and rolling elements is a major component. Fluctuations in raw material prices directly impact the final cost.

Precision Manufacturing Processes: Achieving the required tolerances and surface finishes involves costly processes like precision gear hobbing, grinding, honing, and superfinishing. Heat treatment (case hardening, tempering) requires controlled atmosphere furnaces and skilled operation. These processes demand significant investment in machinery and expertise.

Integrated Slewing Bearing: The cost, size, and quality of the high-capacity slewing bearing (crossed roller, triple-row roller, or ball type) integrated within the drive constitute a substantial portion of the overall unit cost.

Advanced Sealing (IP65): Implementing and validating effective IP65 sealing involves complex seal designs (multiple lip seals, labyrinth paths), high-quality seal materials resistant to wear and chemicals, and rigorous testing, all adding to the manufacturing cost.

Surface Treatments & Finishes: Processes like gear grinding for noise reduction, specialized coatings for enhanced wear or corrosion resistance, and protective surface treatments contribute to the cost but are essential for performance and longevity.

Engineering & Design: Investment in R&D for optimizing gear geometry, bearing integration, structural analysis (FEA), and designing for manufacturability and reliability is amortized into the unit price.

Quality Assurance & Testing: Rigorous quality control throughout manufacturing, including gear inspection (profile, lead, runout), bearing preload checks, functional testing under load, noise testing, and IP rating validation, ensures quality but increases cost.

Order Volume & Customization: Higher production volumes typically lower the per-unit cost through economies of scale. Conversely, any customization – such as special mounting flanges, shaft modifications, unique seal requirements, specific lubricants, or special certifications – increases the price significantly.

Supply Chain & Logistics: Costs associated with sourcing specialized global components, managing inventory, and transportation logistics factor into the final price.

Manufacturer Expertise & Reputation: Suppliers with a proven track record for high-performance, reliable products like the SP-I 0541, backed by strong engineering support and warranties, often command a premium reflecting the reduced risk and higher value for the customer.

Supplier of Lightweight Gear Slewing Drive SP-I 0541

LYRADRIVE is a leading manufacturer specializing in the design and production of high-performance slewing drives, including the Lightweight Gear Slewing Drive SP-I 0541. Renowned for engineering excellence, LYRADRIVE focuses on delivering robust, reliable, and efficient rotary solutions tailored for demanding industrial automation, material handling, and precision motion control applications. Their commitment to utilizing premium materials, implementing stringent precision manufacturing techniques, and incorporating rigorous quality control ensures drives like the SP-I 0541 meet the highest standards for torque capacity, speed, rigidity, and longevity, particularly in challenging environments requiring IP65 protection. LYRADRIVE provides comprehensive technical support to assist customers in selecting, integrating, and maintaining the optimal slewing drive solution, aiming to maximize machine performance and operational efficiency.