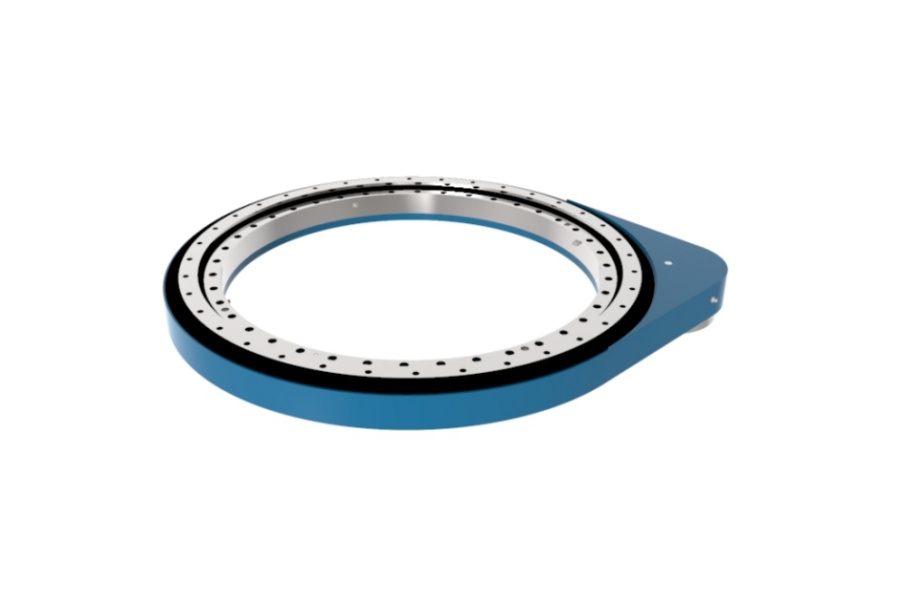

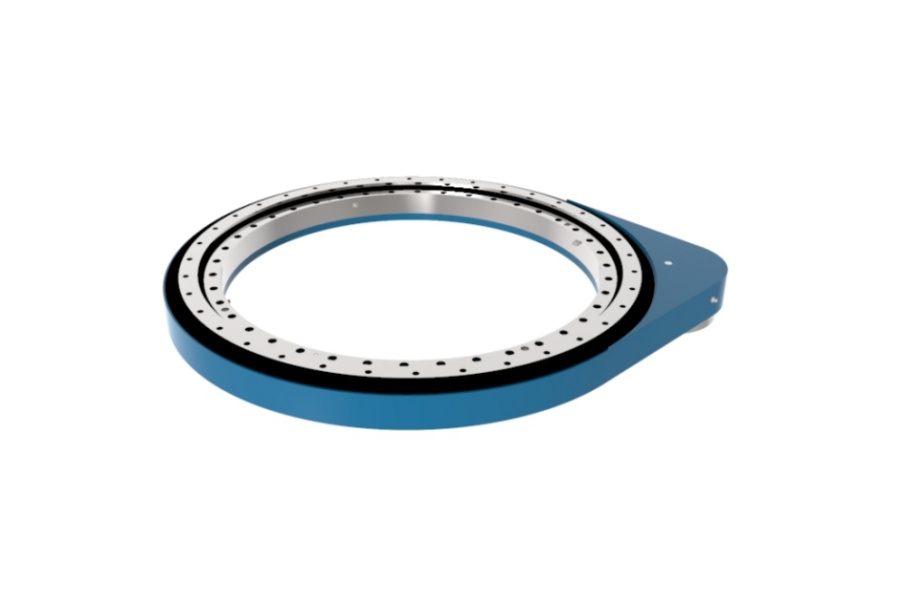

Understanding the Lightweight Slewing Ring Gear Drive SP-I 0741

What is the Lightweight Slewing Ring Gear Drive SP-I 0741?

Lightweight Slewing Ring Gear Drive SP-I 0741 represents a specific class of precision rotational drive systems. Fundamentally, it integrates a compact worm or pinion gear directly engaging a large-diameter internal gear (or ring gear) within a single, rigid housing. This design efficiently transforms input rotational motion (typically from an electric motor) into high-torque, low-speed rotary output capable of handling significant axial, radial, and moment loads. The "Light" designation typically refers to optimized weight-to-performance ratio achieved through material selection, design efficiency, and compact footprint, making it ideal where weight savings are critical without sacrificing strength or durability. The SP-I 0741 model signifies its unique specifications within the manufacturer's product line.

Why Gear Slewing Drives Must Have Backlash

Backlash, the slight clearance between mating gear teeth, is not an imperfection but an essential, deliberately engineered characteristic in gear slewing drives like the SP-I 0741. Eliminating backlash entirely would lead to several detrimental consequences. Firstly, it would cause the gears to bind or jam due to thermal expansion; as components heat up during operation, metals expand, and without clearance, this expansion would create excessive friction, potentially seizing the drive. Secondly, lubrication becomes critical. A small amount of backlash allows lubricant to effectively form a protective film between the meshing teeth surfaces, reducing friction, wear, and heat generation, thereby significantly enhancing the drive's lifespan and efficiency. Thirdly, manufacturing tolerances are not absolute perfection. Backlash accommodates inevitable microscopic variations in gear tooth profiles and alignment during production and assembly, ensuring smooth meshing under real-world conditions. Finally, it prevents excessive preload, which would dramatically increase friction, power consumption, and accelerate component fatigue. While minimizing backlash is crucial for precision and reducing positional error or "wind-up," its complete absence is impractical and destructive for reliable, long-term operation.

Energy Efficiency Ratio of the Lightweight Slewing Ring Gear Drive SP-I 0741

While slewing drives inherently experience energy losses primarily through friction in the gear mesh and bearings, the Lightweight Slewing Ring Gear Drive SP-I 0741 is designed with efficiency in mind. Its specific "energy efficiency ratio" isn't a single published value like an appliance rating, but its performance characteristics strongly indicate favorable energy consumption relative to its output capabilities. Key factors contributing to its efficiency include:

Optimized Gear Design: The helical or specific tooth profile used (based on the module M=4mm) is likely chosen for smoother engagement and lower friction compared to some alternatives, reducing power loss in the critical gear interface.

Precision Manufacturing: High-quality manufacturing ensures accurate tooth geometry and proper meshing alignment, minimizing parasitic friction losses.

Effective Lubrication: Proper lubrication (grease or oil) maintained within the sealed housing drastically reduces friction between meshing teeth and rolling elements in the bearings. The design ensures lubricant reaches the critical contact zones.

High Torque Density: The SP-I 0741 delivers impressive torque (Max Torque Md max = 7450 N.m, Nominal Torque Md nom = 5380 N.m) from a relatively compact unit weighing only 85 kg. This high torque-to-weight ratio implies that less energy is wasted moving the drive's own mass and more energy is directed towards useful work output. Less mass also means lower inertia to overcome during starting and stopping.

Robust Bearing Integration: The integrated slew bearings supporting the axial (Co ax = 1270 kN) and radial loads (Co rad = 480 kN) are designed for low rolling friction.

Although absolute efficiency figures require specific testing conditions, the SP-I 0741's design prioritizes minimizing internal losses, translating to lower power requirements from the driving motor for a given output torque, contributing to overall system energy savings.

Key Features of the Lightweight Slewing Ring Gear Drive SP-I 0741

The SP-I 0741 distinguishes itself through a combination of robust engineering and optimized design:

Exceptional Torque Capacity: Delivers a maximum drive torque (Md max) of 7450 N.m and a nominal drive torque (Md nom) of 5380 N.m, with an equivalent maximum holding torque (Mh) of 7450 N.m, enabling it to handle demanding rotational tasks.

High Load Capacity: Engineered to withstand substantial forces, featuring impressive static load ratings: Axial (Co ax) = 1270 kN and Radial (Co rad) = 480 kN. Its dynamic load capacities (Cax = 270 kN, Crad = 230 kN) ensure reliable performance under operational loads.

Compact and Lightweight: Weighing only 85 kg, it offers a superior strength-to-weight ratio, crucial for applications where minimizing overall system weight is essential (e.g., mobile platforms, aerospace, solar structures).

Precise Gear Ratio: With a gear ratio (i) of 13.8:1 (achieved via a pinion Z1=15 teeth and ring gear Z2=207 teeth), it provides significant speed reduction and torque multiplication for controlled rotation.

Integrated Design: Combines high-capacity bearings, precision gearing (Module M=4mm), and sealing into a single, rigid, pre-assembled unit, simplifying installation and enhancing structural integrity.

Durability and Reliability: Manufactured from high-strength materials (typically hardened alloy steels for gears and races) and featuring effective sealing against contaminants, it is built for long service life in demanding environments.

Smooth Operation: Precision gearing and proper lubrication contribute to relatively smooth and quiet rotation.

Applications of the Lightweight Slewing Ring Gear Drive SP-I 0741

The combination of high torque, significant load capacity, compact size, and relatively light weight makes the SP-I 0741 highly versatile:

Solar Tracking Systems: Ideal for single-axis and dual-axis solar trackers, providing the torque needed to precisely position large solar panels while handling wind and snow loads (axial and radial forces).

Material Handling: Used in crane jibs, manipulator arms, rotary tables, and positioning stages within automated warehouses or production lines where precise rotation under load is required.

Construction Equipment: Applicable in compact crane attachments, drilling equipment positioning heads, and light-duty excavator attachments requiring rotational movement.

Wind Energy: Suitable for smaller wind turbine yaw drives or pitch control mechanisms (though often larger drives are used for main yaw).

Robotics: Provides robust rotational axes for robotic arms and platforms requiring high torque in a compact form factor.

Medical Imaging & Treatment: Used to precisely position components in advanced medical equipment like CT scanners or radiation therapy machines where accuracy and reliability are paramount.

Satellite Communication: Powers the azimuth and elevation movement of satellite dishes for ground stations.

Aerospace Testing: Employed in positioning rigs and simulators for aircraft component testing.

Industrial Automation: Found in indexing tables, welding positioners, and any machinery requiring controlled heavy-duty rotation.

Factors Influencing the Price of Lightweight Slewing Ring Gear Drive SP-I 0741

The cost of the SP-I 0741 is determined by several key factors:

1. Raw Material Costs: Fluctuations in the prices of high-grade alloy steels used for gears, housings, and bearing components significantly impact manufacturing costs.

Manufacturing Complexity & Precision: Producing hardened, ground gears (Module 4) with precise tooth profiles (Z1=15, Z2=207) and integrating them accurately with high-capacity bearings requires advanced CNC machining, grinding, and heat treatment processes. The precision required directly correlates with production time and cost.

Bearing Quality and Size: The integrated slew bearings capable of handling Co ax=1270 kN and Co rad=480 kN represent a substantial portion of the drive's cost. The quality (tolerance class, material, heat treatment) of these bearings is critical.

Quality Control & Testing: Rigorous quality control procedures throughout manufacturing and final testing (e.g., backlash measurement, noise testing, load testing verification) ensure reliability but add to the overall cost.

Sealing and Lubrication: Effective, durable seals to protect internal components from contaminants and high-performance lubricants contribute to the bill of materials and assembly cost.

Order Volume & Customization: Economies of scale apply; larger production runs typically reduce the unit cost. Any deviation from the standard SP-I 0741 specification (e.g., special seals, coatings, shaft modifications) will incur additional engineering and manufacturing expenses.

Overhead and Logistics: Manufacturer's operational costs, R&D investment, and the logistics of shipping a robust 85 kg unit globally influence the final price.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0741

LYRADRIVE is a recognized manufacturer specializing in the design and production of high-performance slewing drives and slew bearings. They focus on delivering precision-engineered solutions like the Lightweight Slewing Ring Gear Drive SP-I 0741, catering to industries demanding reliability, high load capacity, and compact design. LYRADRIVE emphasizes robust engineering, stringent quality control, and technical support to meet the specific rotational drive requirements of their global customer base across diverse sectors. Their expertise lies in integrating powerful gearing and robust bearing technology into efficient, application-ready drive units. For detailed specifications, technical support, and purchasing information regarding the SP-I 0741 and other models, contacting LYRADRIVE directly is recommended.