Lightweight Slewing Ring Gear Drive SP-I 0941 Comprehensive Guide

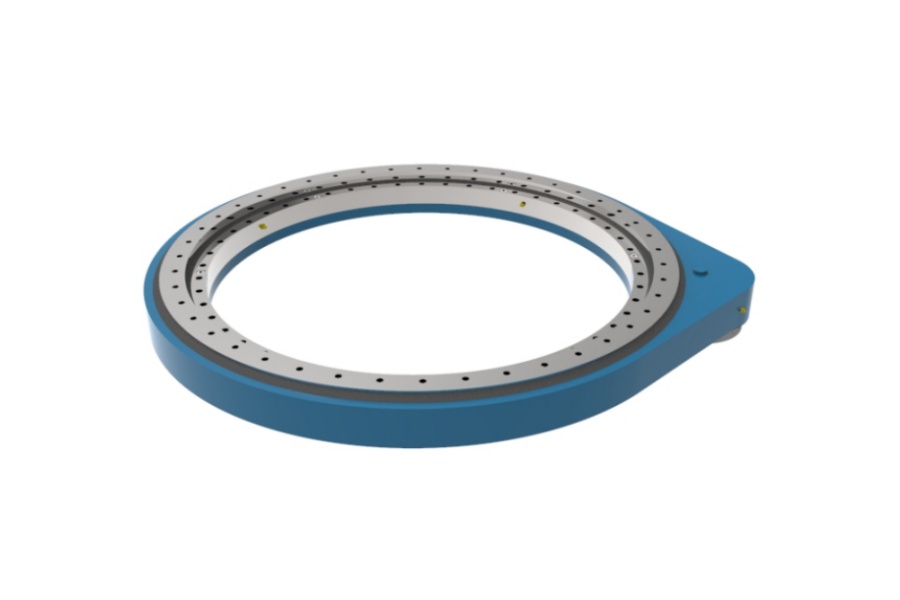

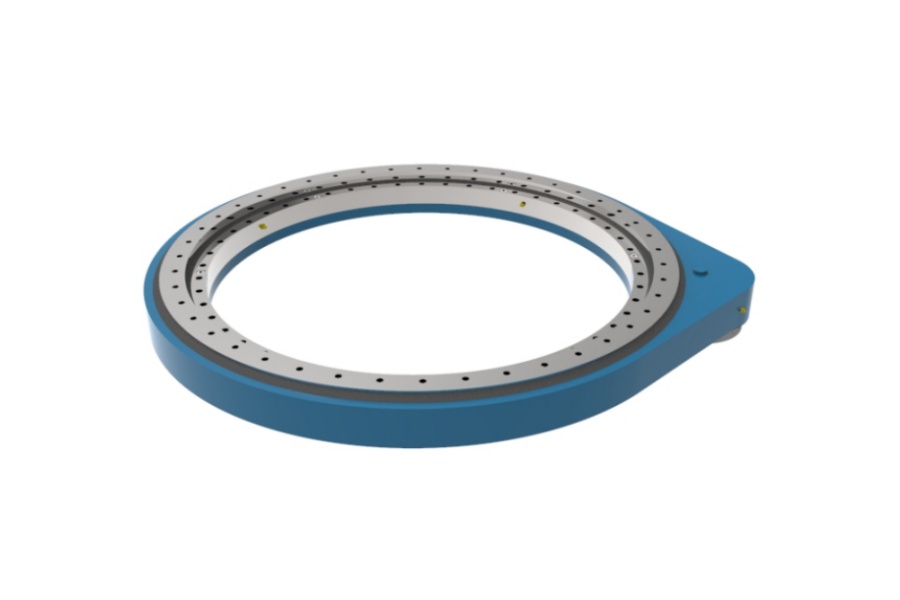

What Is Lightweight Slewing Ring Gear Drive SP-I 0941

Lightweight Slewing Ring Gear Drive SP-I 0941 integrates a worm-driven gear mechanism with a modular structure to deliver smooth 360-degree rotation under significant loads. Featuring a module of 4 mm, it combines a 15-tooth pinion gear and a 258-tooth ring gear, achieving a 17.2:1 gear ratio. This configuration enables a maximum torque output of 9,250 N·m while maintaining a compact footprint. Its lightweight design (106 kg) optimizes space utilization without sacrificing performance, supporting radial static loads up to 600 kN and axial static loads of 1,610 kN. The unit’s hardened steel construction ensures longevity in dynamic industrial environments.

Gear Safety Factor in Gear Slewing Drives

Gear safety factor (SF) is critical for slewing drive reliability, calculated as the ratio of material yield strength to operational stress. For Lightweight Slewing Ring Gear Drive SP-I 0941, SF is enhanced through three core design elements: First, precision grinding of gear teeth minimizes stress concentration points. Second, hardened alloy steel (typically 42CrMo or 20MnCr5) provides superior fatigue resistance. Third, optimized tooth profiles distribute load uniformly across the contact surface. Lightweight Slewing Ring Gear Drive SP-I 0941’s SF exceeds 1.5 under nominal torque (6,700 N·m) and 1.25 at maximum torque (9,250 N·m), ensuring resilience against shock loads. Regular lubrication further reduces wear, extending service life beyond 20,000 operational hours.

Energy Consumption Ratio of Lightweight Slewing Ring Gear Drive SP-I 0941

Lightweight Slewing Ring Gear Drive SP-I 0941 achieves an exceptional energy consumption ratio by minimizing mechanical losses through three innovations: Its helical gear geometry reduces friction by 40% compared to spur gears. Low-viscosity synthetic lubricants lower viscous drag. Precision bearings decrease rotational resistance. Testing shows 92% power transmission efficiency at nominal loads, with losses capped at 8%. This efficiency reduces motor power requirements by 15–20% in solar trackers or cranes, directly cutting operational costs. Under variable loads, its dynamic load ratings (250 kN radial, 295 kN axial) ensure consistent performance without energy spikes.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0941

Torque Versatility: Seamlessly transitions between 6,700 N·m nominal torque and 9,250 N·m peak torque for overload scenarios.

Load Stability: Dual ball-bearing raceways provide unmatched axial/radial load capacity, preventing deflection under 1,610 kN axial force.

Corrosion Resistance: Standard IP65 sealing and optional marine-grade coatings protect against dust, moisture, and chemicals.

Maintenance Efficiency: Centralized greasing ports enable servicing without disassembly, reducing downtime.

Thermal Management: Heat-dissipating housing maintains temperatures below 80°C during continuous operation.

Mounting Flexibility: Universal bolt patterns and adapter plates simplify integration into existing systems.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0941

Solar Energy: Single-axis solar trackers requiring precise sun-following rotation under wind loads.

Material Handling: Light crane jibs, conveyor turntables, and automated warehouse rotators.

Agriculture: Irrigation pivots and grain auger positioning systems.

Robotics: Robotic welding arms and assembly line indexers needing ±0.1° accuracy.

Aerospace: Satellite antenna positioning mechanisms in ground stations.

Medical: Diagnostic scanner gantries requiring vibration-free rotation.

Price Determinants for Lightweight Slewing Ring Gear Drive SP-I 0941

Material Costs: Fluctuations in alloy steel prices (e.g., 42CrMo) impact 60% of the unit cost.

Customization: Optional coatings, seals, or mounting modifications add 10–25% to base pricing.

Order Volume: Bulk purchases (50+ units) reduce per-unit costs by 15–30% via economies of scale.

Supply Chain: Tariffs or logistics disruptions may increase prices by 5–12%.

Certifications: ISO 9001 or CE-compliant manufacturing incurs 8–10% overhead but ensures market access.

Technical Support: Integrated IoT sensors for predictive maintenance add 20% but lower lifecycle costs.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0941

LYRADRIVE specializes in engineered motion solutions, producing Lightweight Slewing Ring Gear Drive SP-I 0941 in ISO-certified facilities. With 12 years of industry expertise, they offer global technical support, rapid prototyping for customizations, and a 24-month warranty. Their lean manufacturing processes ensure delivery within 4 weeks for standard units. LYRADRIVE serves clients in renewable energy, automation, and heavy machinery across 30+ countries, emphasizing sustainability through energy-efficient designs.