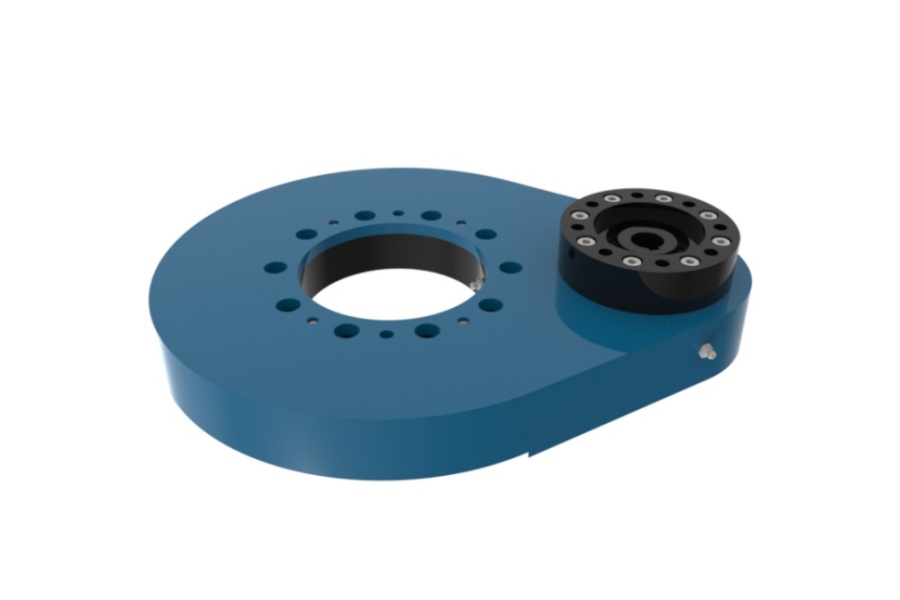

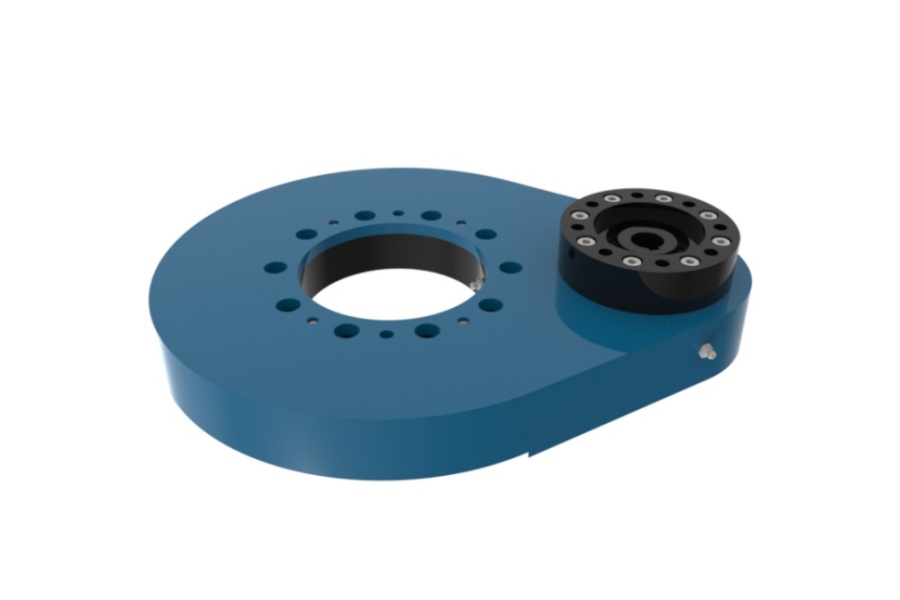

Lightweight Gear Slewing Drive SP-I 0229 Technical Overview

What is Lightweight Slewing Ring Gear Drive SP-I 0229

Lightweight Slewing Ring Gear Drive SP-I 0229 is a compact, integrated drive system designed to deliver rotational motion around a vertical axis. It combines essential components – typically a worm gear set or, in this case, a precision gear set (pinion and gear ring), bearings, housings, seals, and often an integrated mounting structure – into a single, pre-assembled, and lubricated unit. The designation "SP-I 0229" refers to this specific model's size and performance characteristics. Its core function is to transform input rotation (usually from an electric motor mounted directly onto the drive) into slow-speed, high-torque output rotation of the outer ring or housing, while simultaneously supporting substantial axial, radial, and moment loads. The "lightweight" aspect highlights its design optimization, achieving high power density and load capacity relative to its overall mass (35 kg for this model), making it ideal where weight is a critical constraint without compromising on strength or performance. This integration simplifies design, installation, and maintenance compared to sourcing and assembling individual components like large bearings and separate gearboxes.

Impact of Gear Modification Design on Transmission Performance

Gear modification, specifically profile shifting (or "gear tooth correction"), is a critical design technique employed in precision gear sets like those within the SP-I 0229 to optimize performance beyond what standard gears can achieve. This intentional deviation from the theoretical standard tooth profile significantly influences several key transmission characteristics:

Enhanced Load Capacity: Positive profile shifting effectively thickens the root of the driving pinion tooth and the tip of the driven gear tooth. This redistribution of material dramatically increases the tooth root bending strength, allowing the gear set to transmit higher torques (like the SP-I 0229's 2860 Nm max torque) and resist tooth breakage under heavy loads. It also improves surface durability by optimizing the contact pattern and reducing Hertzian contact stress at the tooth flanks.

Reduced Wear and Increased Durability: By optimizing the relative curvature of the meshing tooth profiles, profile shifting minimizes specific sliding velocities and contact pressure peaks at critical points (tip and root regions). This reduction in sliding friction and localized stress directly translates to lower wear rates, reduced risk of scuffing or pitting, and significantly extended operational lifespan for the drive.

Improved Efficiency: Minimizing sliding friction through optimized tooth contact not only reduces wear but also decreases power losses due to friction. This leads to higher overall transmission efficiency, meaning less input power is wasted as heat, contributing to cooler operation and potentially smaller motor requirements.

Noise and Vibration Reduction: Profile shifting allows designers to achieve a more favorable contact ratio and smoother transition of load between meshing teeth. By avoiding undercutting (especially on pinions with low tooth counts like the SP-I 0229's Z1=15) and ensuring conjugate action, gear meshing becomes quieter and generates less vibration. This is crucial for applications requiring smooth, precise motion and low operational noise.

Compensation for Manufacturing and Assembly Tolerances: A small amount of profile shift can be used to compensate for minor center distance deviations that might occur due to manufacturing tolerances or thermal expansion during operation, helping to maintain optimal backlash and meshing conditions.

Avoidance of Undercutting: For pinions with a low number of teeth (common in slewing drives to achieve high reduction ratios like the SP-I 0229's i=5.4), standard gear generation processes can cause undercutting – a weakening notch at the tooth root. Positive profile shifting eliminates this undercutting, preserving the pinion's strength. The design of the SP-I 0229 undoubtedly leverages sophisticated gear modification to achieve its impressive torque ratings (2860 Nm max, 2500 Nm nominal) and high load capacities within its compact, lightweight form factor while ensuring smooth, reliable, and durable operation.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 0229

The SP-I 0229 distinguishes itself through a combination of engineered features delivering robust performance in a weight-conscious design:

Exceptional Torque Density: Delivering a maximum output torque of 2860 Nm and a nominal torque of 2500 Nm from a unit weighing only 35 kg represents outstanding torque-to-weight ratio. This high power density is a hallmark of its lightweight classification.

High Load Capacity: Engineered to withstand substantial forces, it offers remarkable static load ratings of 440 kN axially and 155 kN radially. Its dynamic load ratings are similarly impressive at 170 kN axially and 145 kN radially, enabling it to handle significant operational stresses over its service life.

Robust Holding Torque: The maximum holding torque of 2860 Nm ensures excellent resistance to back-driving and provides stable positioning even under substantial static loads or moments, crucial for safety and precision in many applications.

Optimized Gear Design: Featuring a module 4 gear set with a pinion (Z1=15) driving a large gear ring (Z2=81), achieving a 5.4:1 reduction ratio. This design, incorporating advanced gear modification techniques as discussed, ensures high strength, smooth operation, low noise, and long service life under demanding conditions.

Integrated Design: Precisely manufactured and assembled as a complete unit with high-quality bearings and seals. This integration guarantees optimal alignment, pre-loading, and lubrication from the factory, simplifying installation, enhancing reliability, and reducing maintenance requirements compared to custom-built solutions.

Compact Footprint: The integrated nature and optimized gearing contribute to a relatively compact size for its performance class, saving valuable space in machinery design.

Precision Motion Control: The precision-ground gears and robust bearing arrangement ensure low backlash, smooth rotation, and accurate positioning capabilities.

Sealed and Lubricated: Typically supplied pre-filled with high-performance grease and equipped with effective seals, protecting internal components from contamination and ensuring long-term lubrication, suitable for various industrial environments.

Applications of Lightweight Slewing Ring Gear Drive SP-I 0229

The unique blend of compactness, light weight, high torque, and significant load capacity makes the SP-I 0229 exceptionally versatile across numerous industries:

Solar Tracking Systems: Ideal for single-axis and smaller dual-axis solar trackers, where minimizing weight on the support structure is paramount while needing sufficient torque to rotate panels and withstand wind loads. Its high holding torque ensures panel stability.

Material Handling Equipment: Used in compact crane jibs, light-duty rotary tables, positioners for welding or assembly, and automated guided vehicle (AGV) turntables requiring precise rotation under load.

Robotics and Automation: Provides the rotational axis for robotic arms, indexing tables, tool changers, and other automated machinery components where space and weight constraints exist alongside the need for precise motion and load support.

Medical and Laboratory Equipment: Suited for rotational stages in imaging devices (like CT scanner components), patient positioning tables, and laboratory automation equipment demanding smooth, precise, and reliable motion.

Packaging and Processing Machinery: Employed in rotary fillers, cappers, labelers, and indexing conveyors where compact drives enable rotational movement of stations or products.

Defense and Aerospace: Used in antenna positioning systems (ground stations, vehicle-mounted), sensor turrets, and actuation systems for hatches or panels where weight savings are critical.

Construction Equipment: Applicable in light-duty excavator attachments, compact drilling rigs, or surveying equipment requiring rotational positioning.

Agriculture: Potential use in specialized sprayer booms, sensor platforms, or automated feeding systems.

Renewable Energy (Wind Auxiliary Systems): For adjusting smaller nacelle components, yawing small turbines, or positioning maintenance platforms.

Factors Influencing Lightweight Slewing Ring Gear Drive SP-I 0229 Pricing

The cost of the SP-I 0229 slewing drive is not fixed and is influenced by several key variables:

Material Specifications: The base price assumes standard high-quality alloy steels for gears and housings. Opting for premium alloys (e.g., case-hardened steels with superior core properties), specialized surface treatments (nitriding, specialized coatings like DLC for extreme wear resistance), or corrosion-resistant materials (stainless steel components, special platings) significantly increases raw material and processing costs.

Manufacturing Precision and Tolerances: Achieving the high gear quality (AGMA class or DIN standards), precise bearing fits, low backlash requirements, and overall dimensional accuracy demanded by such a compact, high-performance unit requires advanced machining centers, skilled labor, rigorous quality control (including gear testing like CMM or noise/vibration analysis), and potentially specialized grinding processes. Tighter tolerances directly correlate with higher manufacturing costs.

Bearing Quality and Type: The integrated bearings are critical to performance. Using standard high-capacity roller bearings meets the base spec. However, specifying premium bearings from top-tier manufacturers (SKF, FAG, Timken, NSK), bearings with special clearance grades (C3, C4), enhanced sealing, or customized pre-load settings adds cost.

Sealing and Environmental Protection: Standard sealing (typically radial shaft seals and O-rings) is included. Requirements for enhanced IP ratings (e.g., IP65, IP67), specialized seal materials (Viton, PTFE) for chemical resistance or extreme temperatures, or labyrinth seals for very high-speed or dirty environments increase cost.

Lubrication: Standard high-performance grease is included. Specifying special greases (food-grade NSF H1, wide temperature range -40°C to +150°C+, extreme pressure additives) or requesting an initial fill with synthetic oil adds expense.

Customization: Any deviation from the standard SP-I 0229 model incurs additional costs. This includes modifications like special flange patterns or mounting holes, custom shaft configurations (different diameters, lengths, keyways, splines), unique paint or surface finishes, integrated sensors (absolute encoders, temperature sensors), or special backlash settings.

Order Volume: Significant economies of scale apply. Purchasing large quantities typically results in substantial per-unit discounts compared to buying single units or small batches. Long-term supply agreements can also influence pricing favorably.

Supplier Value-Added Services: Costs may reflect additional services like comprehensive technical support during integration, extensive product documentation (3D models, detailed installation manuals), extended warranty periods, or vendor-managed inventory programs.

Market Factors: Fluctuations in the cost of raw materials (steel, alloys), energy prices impacting manufacturing, and global supply chain dynamics can cause baseline price variations over time.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 0229

The Lightweight Slewing Ring Gear Drive SP-I 0229 is manufactured and supplied by LYRADRIVE. LYRADRIVE specializes in the engineering, production, and global distribution of high-performance slewing drives, slewing bearings, and related motion control solutions. They focus on delivering robust, reliable, and precisely engineered products tailored to meet demanding application requirements across diverse industries like renewable energy, industrial automation, material handling, and construction. LYRADRIVE emphasizes quality manufacturing processes, rigorous testing, and provides technical expertise to support customers in selecting and integrating the optimal drive solution, such as the SP-I 0229, into their specific machinery and systems.