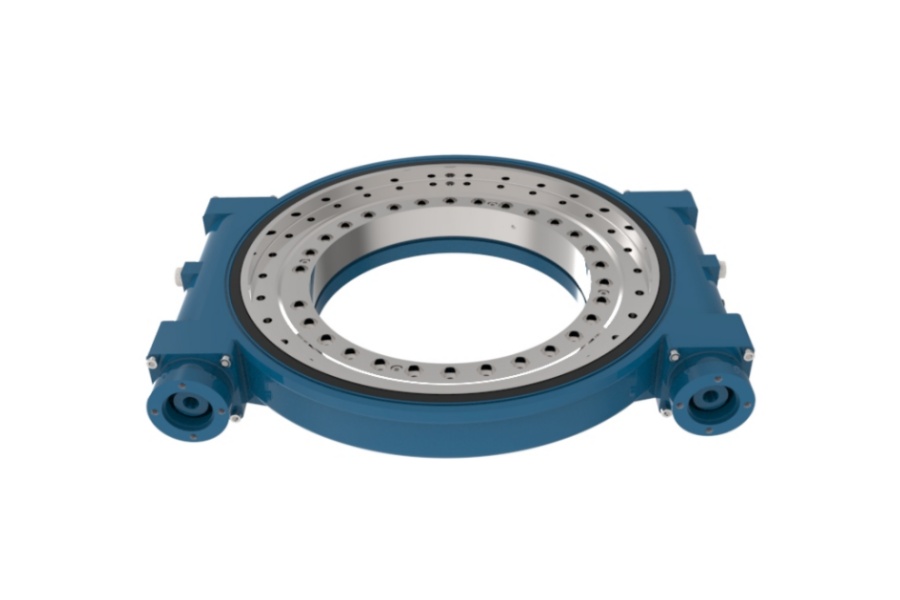

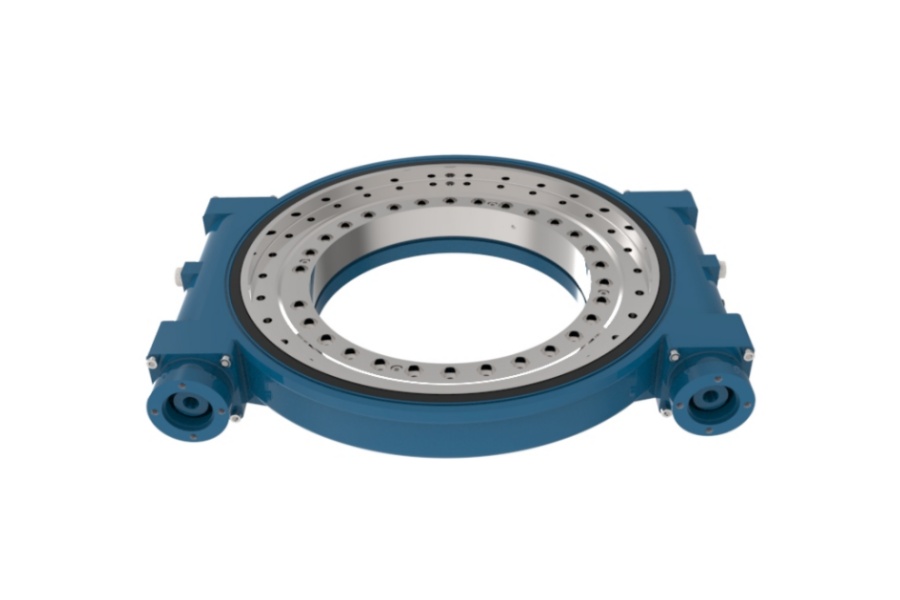

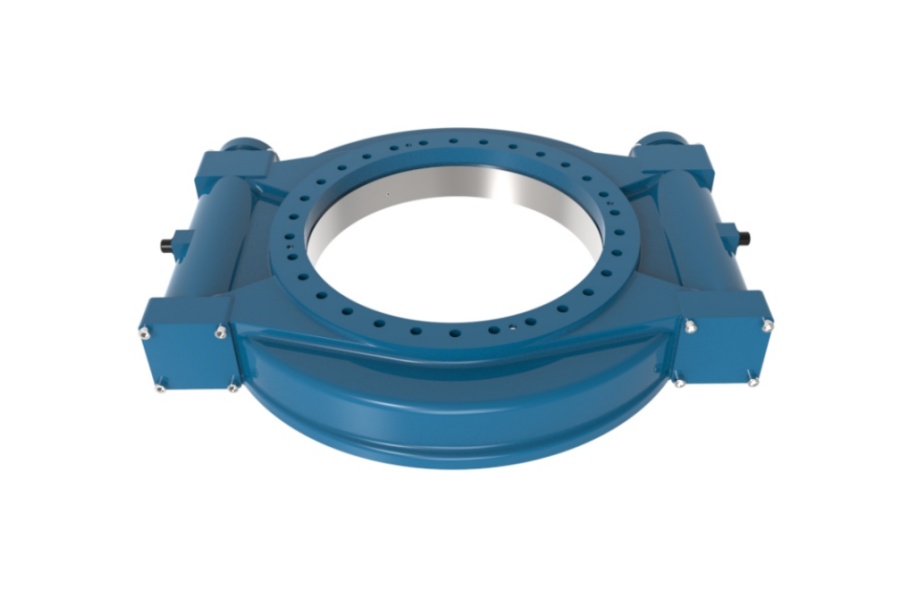

Double Worm Slewing Drive WED21 High Torque Precision

What is Double Worm Slewing Drive WED21

Double Worm Slewing Drive WED21 is a compact, high-capacity slewing drive unit utilizing two precisely matched worm gears simultaneously engaging a central worm wheel. This unique configuration, distinct from single-worm drives or crossed-roller bearings, distributes the load symmetrically across the drive mechanism. Key to its performance is the elimination of internal backlash inherent in single-worm designs. As one worm naturally pushes the wheel teeth in one direction, the opposing worm applies counter-pressure, effectively locking the teeth against both flanks of the worm wheel. This inherent preload ensures true zero-backlash operation, critical for applications requiring high positional accuracy and rigidity under varying loads. The robust construction, incorporating high-strength materials and precision manufacturing, allows the WED21 to achieve remarkable output torque (48 kN.m) and withstand substantial tilting moments (203 kN.m) and holding torque (179.8 kN.m), all within a remarkably compact footprint weighing only 195 kg.

Double Worm Slewing Drive WED21 Energy Consumption Comparison

The dual worm design of the WED21 fundamentally impacts its efficiency profile compared to alternative drive systems. While worm gear drives generally operate at lower peak efficiencies (typically 40-85%) than planetary or helical gear sets due to sliding friction, the WED21 offers distinct advantages within its class and for its intended applications:

Versus Single Worm Drives: The dual worm system achieves superior positional holding with minimal energy input. Once positioned, the inherent preload and friction within the dual worm system significantly reduce or eliminate the need for continuous motor power to maintain position against external loads (holding torque 179.8 kN.m). This "power-off" holding capability leads to substantial energy savings, particularly in static or intermittently moving applications like positioning stages or holding jigs, compared to systems requiring constant servo motor current for holding.

Versus High-Efficiency Gearboxes + Brakes: While spur or planetary gearboxes might offer higher transmission efficiency during motion, achieving comparable holding torque and zero-backlash rigidity often requires adding an external brake mechanism. The energy consumed by an engaged electromagnetic brake (even holding current) plus the base transmission losses can often exceed the static holding losses of the integrated dual worm system. The Double Worm Slewing Drive WED21 provides integrated high holding torque without an additional energy-consuming component.

Optimization Focus: The Double Worm Slewing Drive WED21 design prioritizes high torque density, rigidity, zero-backlash, and holding capacity within a compact space – factors often more critical than peak transmission efficiency for its typical heavy-duty, precision positioning tasks. Energy savings are primarily realized through its exceptional static holding performance without external power.

Analysis of Cooling Methods for High-Speed Spur Gear Rotary Drives

While the WED21 utilizes a robust worm gear system optimized for high torque rather than extreme speeds, understanding cooling for high-speed rotary drives, particularly spur gear types, is valuable context. Spur gear drives, common in high-speed applications, generate significant heat from friction, windage, and churning losses. Effective cooling is paramount to prevent lubricant breakdown, premature wear, and loss of dimensional stability. Key methods include:

Air Cooling: The simplest method, relying on natural convection or forced air (fans) over the drive housing. Surface area is increased using fins. Effective for moderate speeds and loads but often insufficient for very high power density or high ambient temperatures.

Lubricant Circulation Systems: A dedicated pump circulates oil from a sump through an external heat exchanger (cooler) and back into the drive. This actively removes heat from critical meshing points and bearings. Filtration is often integrated. Essential for high-power, high-speed spur gear drives.

Water/Glycol Jacket Cooling: Channels machined into or jackets attached to the drive housing circulate coolant (water/glycol mix). Provides highly efficient heat removal directly from the housing structure, ideal for applications with strict temperature limits or very high heat loads. Common in high-performance industrial settings.

Oil Mist/Lubrication Systems: Deliver a fine mist or spray of cooled lubricant directly onto gear meshes and bearings. Provides lubrication and cooling simultaneously, with the atomized oil offering excellent heat transfer characteristics.

Material & Design Selection: Using materials with high thermal conductivity (e.g., specific aluminum alloys) for housings aids heat dissipation. Optimizing gear geometry to minimize friction losses and churning also reduces heat generation at the source. Sufficient oil volume and sump size act as a heat sink.

The WED21's worm gear design, operating at lower relative speeds than high-RPM spur gears, generally produces less windage and churning heat. Its robust construction and typical application loads often make natural convection or moderate forced air sufficient. However, for very high duty cycles or extreme ambient conditions, forced air or even circulating oil systems can be specified.

Double Worm Slewing Drive WED21 Features

The WED21 integrates a suite of advanced features engineered for maximum performance and reliability in demanding conditions:

Exceptional Torque & Load Capacity: Delivers high output torque (48 kN.m), handles massive tilting moments (203 kN.m), provides superior holding torque (179.8 kN.m), and withstands significant static axial (1598 kN) and radial (640 kN) loads, plus dynamic axial (385 kN) and radial (335 kN) loads.

True Zero Backlash: The dual worm, opposing action preload mechanism fundamentally eliminates internal backlash, crucial for precision positioning, repeatability, and system rigidity under reversing loads.

High Precision: Offers excellent tracking precision (≤ 0.1°), enabling accurate positioning and smooth motion control.

Compact & Lightweight Design: Achieves its high performance within a remarkably space-efficient and relatively lightweight (195 kg) package, simplifying integration into machinery.

High Reduction Ratio: The standard 90:1 gear ratio provides significant speed reduction and torque multiplication from a compact motor input.

Integrated Design: Combines bearings, gearing, seals, and often mounting interfaces into a single, pre-assembled, and lubricated unit, simplifying installation and maintenance.

Robust Construction: Manufactured from high-strength alloy steels and premium materials, hardened and ground for wear resistance and long service life.

Sealed for Protection: High-quality seals protect internal components from contaminants like dust, dirt, and moisture, enhancing reliability in harsh environments (specific IP rating varies by configuration).

Smooth Operation: Precision manufacturing ensures low vibration and quiet running characteristics.

Double Worm Slewing Drive WED21 Applications

The unique combination of power, precision, compactness, and rigidity makes the WED21 ideal for a wide range of demanding rotary applications across diverse industries:

Heavy Machinery: Articulation joints for excavator booms, crane jibs, heavy-duty positioning tables, ladle tilt mechanisms, robotic welding positioners.

Material Handling: Rotary tables for indexing heavy workpieces, pallet changers, large manipulator arms, automated storage and retrieval system (AS/RS) rotators.

Renewable Energy: Solar tracker azimuth and elevation drives (especially in harsh environments requiring high rigidity and holding torque), pitch drives for smaller turbines or testing rigs.

Industrial Automation: Precision indexing tables for machining centers, assembly robots requiring high moment stiffness, inspection station rotators, high-precision welding turntables.

Defense & Aerospace: Turret drives for radar, surveillance, or weapon systems, missile launcher positioning, antenna pedestals requiring precise pointing under load.

Medical Equipment: Positioning heavy components in imaging systems (CT/MRI), radiation therapy gantries requiring smooth, precise motion.

Packaging Machinery: Rotary indexers for handling heavy containers or filled packages.

Test & Simulation: Positioning heavy test articles on shakers or within environmental chambers, fatigue testing rigs.

Factors Influencing Double Worm Slewing Drive WED21 Price

The cost of a WED21 unit is influenced by several key factors:

Material Specifications: The grade of alloy steels used for worms, wheel, and bearings significantly impacts cost. Higher grades offer better strength, wear resistance, and longevity. Housing material (e.g., cast iron vs. ductile iron vs. specialized aluminum) also affects price.

Manufacturing Precision & Finishing: Achieving ≤0.1° precision and true zero backlash requires advanced machining (grinding, honing), meticulous quality control, and specialized assembly processes, increasing manufacturing cost.

Heat Treatment Processes: Critical hardening (case hardening, induction hardening) and tempering processes necessary for durability and wear resistance add cost.

Bearing Quality & Type: The size, quality (precision class), and type (e.g., standard vs. premium branded) of the integrated slew bearings are major cost components.

Sealing & Protection (IP Rating): Higher levels of ingress protection (e.g., IP65, IP67) require more sophisticated and durable sealing solutions, increasing cost. Special seals for extreme environments add more.

Lubrication System: Standard grease lubrication is common. Options for centralized lubrication systems or specific high-performance greases add cost.

Customization: Modifications from the standard WED21 design (e.g., special mounting flanges, shaft configurations, input interfaces, custom backlash settings, special surface treatments) incur engineering and production costs.

Order Quantity (MOQ): Economies of scale apply. Larger order quantities typically reduce the unit price.

Market Factors: Raw material costs, energy prices, labor rates, and global supply chain conditions fluctuate and impact the final price.

Supplier Value-Add: Technical support, design services, warranty terms, lead time reliability, and brand reputation also factor into the overall value proposition and pricing.

Supplier of Double Worm Slewing Drive WED21

LYRADRIVE is a recognized leader in the design, engineering, and manufacturing of high-performance rotary drive solutions, specializing in slewing rings, slew drives, and custom rotary systems. With extensive expertise in gear technology and bearing design, LYRADRIVE produces the robust and precise Double Worm Slewing Drive WED21 series. They offer comprehensive support from initial application engineering through manufacturing and after-sales service, catering to global industrial sectors demanding reliability and performance in critical motion control applications. LYRADRIVE's commitment to quality and innovation makes them a trusted partner for integrating the advanced capabilities of the WED21 into complex machinery.