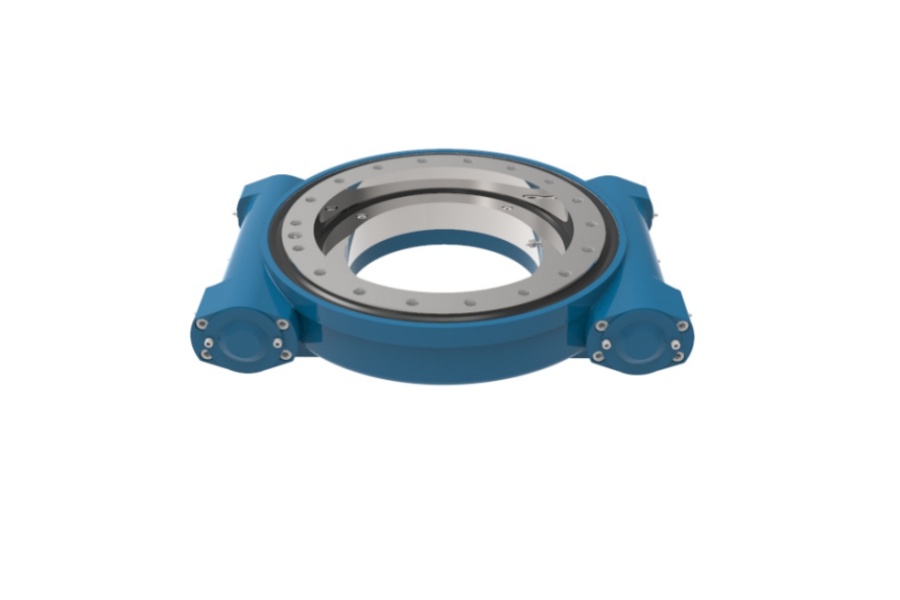

Double Worm Slewing Drive WED14 Unmatched Power and Precision in Motion Control

What is Double Worm Slewing Drive WED14

Double Worm Slewing Drive WED14 is an integrated slewing drive mechanism engineered to deliver superior power transmission for demanding rotational applications. Unlike conventional single-worm rotary drives, the WED14 incorporates a revolutionary dual-worm gear design. This configuration features two precisely matched worm screws positioned to simultaneously engage a central worm wheel (sector gear) from diametrically opposed sides. This symmetrical force application fundamentally enhances the drive's mechanical capabilities compared to single-worm alternatives. The WED14 is specifically designed as a robust and compact solution where high torque output, exceptional positional stability, and resistance to shock loads are paramount requirements. It provides a direct, reliable means of converting rotary input motion into high-torque, low-speed rotational output, often directly mounting onto the driven structure.

The Critical Role of Anti-Backlash Worm Gearing

At the heart of the WED14's exceptional performance lies its sophisticated anti-backlash worm gearing system. Backlash, the slight angular movement or "play" between meshing gear teeth when reversing direction, is a major source of inaccuracy, vibration, and wear in transmission systems. The dual-worm design inherently combats this issue. The two worms are preloaded against the worm wheel teeth, typically using an adjustable spring mechanism or precision shimming integrated within the housing. This preload forces the teeth of both worms to maintain constant contact with the flanks of the worm wheel teeth, effectively eliminating any clearance in the mesh. This constant tooth contact ensures virtually zero backlash, translating into crucial operational benefits: significantly enhanced positional accuracy and repeatability, smooth and precise motion even during reversals, elimination of the characteristic "chatter" or "jump" when changing direction, reduced wear on gear teeth due to the elimination of impact loads from lost motion, and minimized vibration transmission, contributing to smoother overall system operation and longer component life. This anti-backlash feature is essential for applications requiring pinpoint accuracy, such as robotic positioning, optical tracking, or precision machining rotary tables.

Exceptional WED14 Static Holding Torque

One of the most defining characteristics of the Double Worm Slewing Drive WED14 is its remarkable static holding torque capability, rated at an impressive 82 kN.m. Static holding torque refers to the maximum external torque that the drive can withstand and hold stationary without any input power applied to the worm shafts, preventing unintended rotation of the output stage. This capability arises directly from the fundamental mechanics of the worm gear principle combined with the dual-worm configuration. Worm gears are inherently self-locking under static conditions due to the high friction angle in the worm thread; the worm can easily drive the wheel, but the wheel cannot back-drive the worm. The WED14 leverages this principle doubly. With two worms preloaded against the wheel, the self-locking effect is significantly amplified. The force required to overcome friction and potentially back-drive both worms simultaneously is substantially higher than for a single worm. Furthermore, the symmetrical force distribution ensures that the holding force is evenly applied across the worm wheel, maximizing stability. This immense holding torque (82 kN.m) far exceeds the drive's nominal output torque (16.2 kN.m), providing an inherent safety factor. It ensures the driven load remains securely locked in position even under substantial external forces, vibrations, or when the drive motor is de-energized, making it ideal for safety-critical applications like cranes, lifts, heavy positioning stages, or vertical axes where uncontrolled movement is unacceptable.

Distinctive Features of the Double Worm Slewing Drive WED14

The WED14 stands out due to a combination of advanced engineering features that deliver tangible performance advantages:

Dual-Worm Drive System: The core innovation, enabling significantly higher torque output, superior holding torque, and inherent anti-backlash performance compared to single-worm drives. Force distribution is balanced.

High Torque Density: Delivers exceptional output torque (16.2 kN.m) and holding torque (82 kN.m) relative to its physical size and mounting footprint, optimizing space utilization in machinery.

Extreme Rigidity and Torsional Stiffness: The robust housing construction, large bearing sets, and dual-worm preloading create an incredibly stiff structure. This minimizes deflection under load, ensuring precise positioning and accurate force transmission.

Superior Tilt Moment Capacity: Withstands substantial off-axis loads up to 71.2 kN.m, crucial for applications where the load exerts significant cantilevered forces or moments on the drive's output flange.

Integrated Design: Combines high-capacity bearings, sealing, lubrication, and the gearing into a single, pre-assembled, and sealed unit. This simplifies installation, reduces maintenance needs, and enhances reliability.

High Precision and Repeatability: The anti-backlash design and rigid construction enable very high tracking precision (≤ 0.13°) and excellent repeatability of rotational position.

Smooth and Quiet Operation: Precision manufacturing and the constant tooth contact inherent in the preloaded dual-worm system contribute to exceptionally smooth motion transmission and lower operating noise levels.

Robust Construction: Manufactured from high-strength materials (e.g., hardened steel worms, phosphor bronze wheel) and designed for demanding environments and long service life.

Compact Footprint: Designed to offer its high performance within the same or similar envelope as other drives in its class, facilitating upgrades or space-constrained designs.

High Efficiency (for Worm Gear Type): While worm gears typically have lower efficiency than some other gear types, the precision and optimized tooth geometry in the WED14 aim for the highest achievable efficiency within this robust and self-locking design principle.

Diverse Applications Demanding WED14 Performance

The unique combination of high torque, zero backlash, immense holding force, rigidity, and compactness makes the WED14 indispensable across numerous demanding sectors:

Solar Energy: Powering the precise azimuth and elevation axes of large-scale solar tracker systems, handling heavy panel arrays while maintaining accurate sun-following positioning against wind loads.

Heavy Machinery & Construction Equipment: Used in crane jib rotation, excavator attachments, concrete pumpers, drilling rigs, and material handling turntables requiring robust torque transmission and secure holding.

Industrial Automation & Robotics: Enabling precise rotation of heavy workpieces on welding positioners, indexing tables in machining centers, heavy-duty robotic arms (especially base rotation), and automated assembly lines where accuracy and rigidity are critical.

Medical Imaging: Providing smooth, precise, and vibration-free rotation for components within advanced CT scanners, MRI machines, and radiation therapy equipment where image quality and patient safety are paramount.

Defense & Aerospace: Utilized in radar antenna positioning systems, missile launcher turntables, weapon mounts, and ground support equipment demanding high performance, reliability, and resistance to shock/vibration.

Packaging & Material Handling: Driving heavy rotary indexing tables, palletizers, depalletizers, and large conveyor diverters requiring reliable high-torque rotation and positional accuracy.

Stage & Entertainment Technology: Controlling the movement of heavy lighting trusses, large video screens, and complex stage machinery where safety (holding torque) and smooth, precise motion are essential.

Test & Simulation Equipment: Providing controlled rotation for heavy loads in fatigue testing rigs, flight simulators, and other applications requiring high torque and precise motion control under load.

Marine & Offshore: Used in deck cranes, winch drives, hatch covers, and positioning systems on vessels and platforms facing harsh environmental conditions.

Factors Influencing Double Worm Slewing Drive WED14 Pricing

The cost of a Double Worm Slewing Drive WED14 is influenced by several key factors stemming from its complex engineering and high-performance nature:

Raw Material Costs: The substantial quantities of high-grade steel for the housing, shafts, and worms, along with specialized bronze alloys for the worm wheel, directly impact the base price. Fluctuations in global metal markets affect this.

Precision Manufacturing & Machining: Producing the WED14 requires state-of-the-art CNC machining centers capable of holding extremely tight tolerances on complex gear geometries and bearing seats. The grinding of hardened worm threads and precision honing of the worm wheel are particularly critical and costly processes. The dual-worm system doubles the precision worm machining requirement compared to a single-worm drive.

Heat Treatment Processes: Essential hardening processes like case hardening or induction hardening for the worms and specific components significantly enhance wear resistance and longevity but add manufacturing steps and cost.

Bearing Quality & Capacity: The WED14 incorporates large-diameter, high-capacity slewing bearings designed to handle the substantial radial, axial, and moment loads. The quality (ABEC rating, material, sealing) and size of these bearings are major cost factors.

Quality Control & Testing: Rigorous quality control throughout manufacturing, including gear inspection (profile, lead, pitch), bearing runout checks, and final assembly testing (often including torque and backlash verification), ensures reliability but adds expense.

Anti-Backlash Mechanism Complexity: The design, precision components (springs, adjustment mechanisms), and assembly time required to achieve and maintain the critical preload for zero backlash contribute significantly to the cost.

Sealing & Protection: Effective sealing (lip seals, labyrinth designs) to prevent ingress of contaminants and retain lubrication, especially for IP-rated versions for harsh environments, involves specific materials and design complexity.

Customization: While the WED14 is a standard model, modifications such as special input shaft configurations (keyways, splines, flanges), specific mounting hole patterns, special coatings, alternative sealing solutions, or unique lubrication ports incur additional engineering and production costs.

Order Volume & Supply Chain: Economies of scale apply; larger orders typically reduce the unit cost. Global supply chain stability for raw materials and components also influences final pricing.

Brand Reputation & Engineering Support: Investment in R&D, application engineering support, and the manufacturer's reputation for quality and reliability are reflected in the product's value proposition and price.

Supplier of Double Worm Slewing Drive WED14

LYRADRIVE is a recognized specialist in the design and manufacturing of high-precision slewing drives, rotary actuators, and custom motion control solutions. With a strong focus on engineering excellence and innovation, LYRADRIVE has developed a reputation for producing robust, reliable drives capable of meeting the stringent demands of heavy industrial, solar tracking, automation, and specialized applications globally. Their product portfolio, which includes the advanced WED14 series, is characterized by rigorous quality control, application-specific expertise, and a commitment to providing durable and high-performance drive systems for critical operations. Engineers and designers turn to LYRADRIVE for solutions requiring exceptional torque, precision, rigidity, and long-term reliability in challenging environments.