Open Housing Slewing Drive S19 Guide

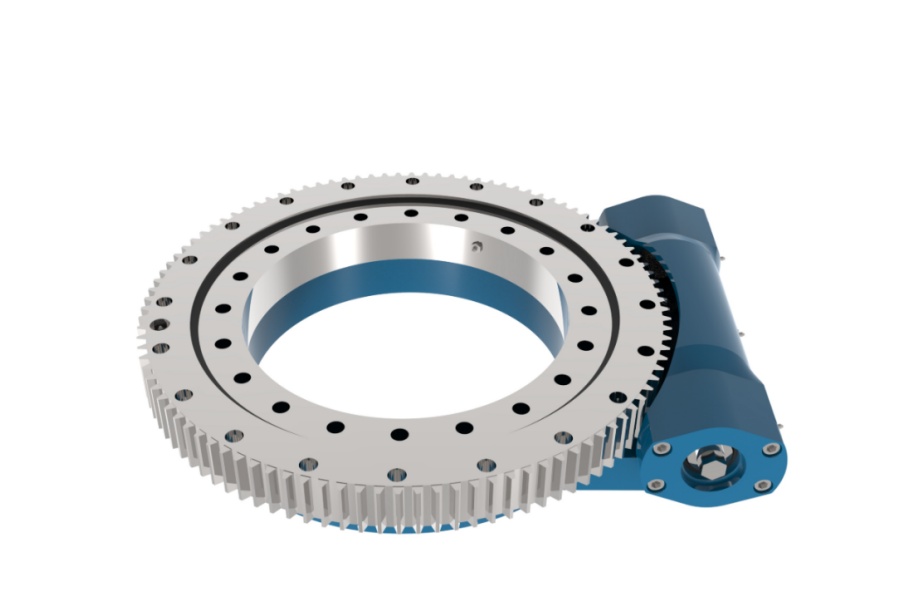

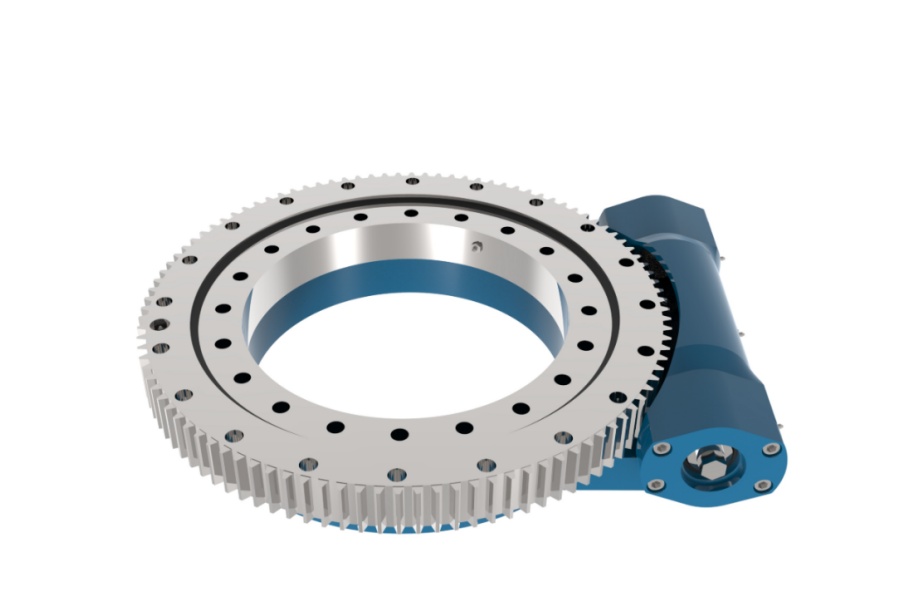

What Is Open Housing Slewing Drive S19

Open Housing Slewing Drive S19 is a premium-grade rotational drive system comprising three core components: a reinforced base structure, precision-machined worm shaft, and optimized worm gear assembly. This advanced configuration delivers exceptional performance in managing combined load conditions including axial forces, radial stresses, and tilting moments, establishing it as an ideal solution for demanding mechanical applications requiring both power and precision.

Wind Power Slewing Bearing S19

The S19 series incorporates specialized wind power slewing bearing technology designed to withstand the extreme operational demands of renewable energy applications. Its hardened raceways and optimized gear tooth profile ensure reliable performance in variable wind conditions while maintaining smooth rotation under substantial dynamic loads. The bearing’s enhanced sealing system provides superior protection against environmental contaminants, significantly extending service intervals in harsh operating environments.

Open Housing Slewing Drive S19 Technical Specifications

The Open Housing Slewing Drive S19 delivers exceptional performance metrics:

Output Torque: 19 kN·m

Tilting Moment Capacity: 176 kN·m

Static Holding Torque: 80.5 kN·m

Gear Reduction Ratio: 116:1

Positioning Accuracy: ≤ 0.15°

Operating Temperature Range: -40°C to +80°C

Protection Rating: IP65 standard (higher available upon request)

These parameters demonstrate the drive’s capability to handle rigorous industrial applications while maintaining precise motion control.

Key Features of Open Housing Slewing Drive S19

The S19 model incorporates several advanced engineering features:

Modular Construction enables flexible integration with various mechanical systems

Optimized Heat Treatment Process enhances component durability and wear resistance

Pre-loaded Antifriction Bearings minimize backlash for improved positioning accuracy

Accessible Lubrication Points simplify maintenance procedures

Corrosion-Resistant Surface Treatments extend service life in harsh environments

Customizable Mounting Configurations accommodate diverse installation requirements

These characteristics combine to deliver reliable performance in the most demanding operating conditions.

Industrial Applications of Open Housing Slewing Drive S19

The S19 drive system serves critical functions across multiple sectors:

Wind Energy Systems: Pitch and yaw control mechanisms for turbine positioning

Heavy Construction Equipment: Rotating platforms for cranes and drilling rigs

Material Handling: Automated warehouse turntables and conveyor diverters

Defense Systems: Weapon platform stabilization and tracking mechanisms

Industrial Automation: Robotic welding positioners and assembly line rotators

Marine Equipment: Deck crane rotation systems and radar positioning units

Its robust construction and precision performance make it particularly valuable in applications where reliability and accuracy are paramount.

Pricing Determinants for Open Housing Slewing Drive S19

Several key factors influence the market price of the S19 drive system:

Material Specifications: High-grade alloy steel components command premium pricing

Production Volume: Economies of scale affect per-unit costs for large orders

Custom Engineering Requirements: Specialized modifications increase development expenses

International Logistics: Shipping costs and import duties impact final pricing

Ancillary Systems: Optional accessories like encoders or brakes affect total cost

Market Conditions: Raw material price fluctuations and currency exchange rates create variability

Understanding these variables helps buyers make informed procurement decisions aligned with their technical and budgetary requirements.

Trusted Supplier of Open Housing Slewing Drive S19

LYRADRIVE stands as a premier global manufacturer of high-performance slewing drive solutions, with the Open Housing Slewing Drive S19 representing one of their flagship products. The company combines advanced engineering expertise with stringent quality control measures to deliver reliable drive systems for critical industrial applications across multiple continents. LYRADRIVE maintains ISO-certified production facilities and offers comprehensive technical support throughout the product lifecycle.