A Comprehensive Introduction of Double Worm Slewing Drive WED17

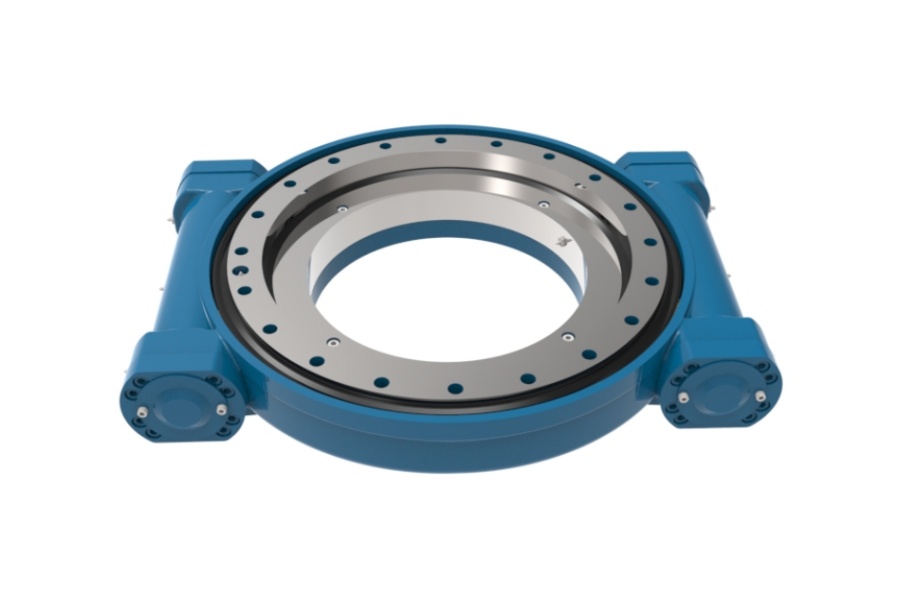

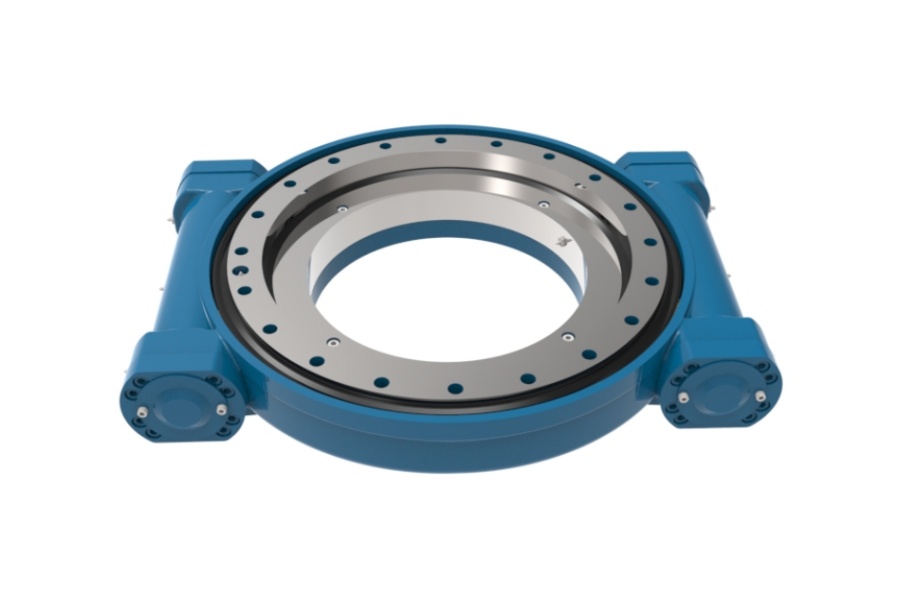

What is the Double Worm Slewing Drive WED17?

The double worm slewing drive WED17 is a revolutionary mechanical device that combines the benefits of worm gear technology with a dual-worm configuration. At its core, the WED17 consists of two precision-engineered worms that mesh with a single worm gear. This design allows for a more efficient transfer of power, resulting in higher output torque and improved load-bearing capabilities. The WED17 is also equipped with a high-quality slewing bearing, which provides smooth and stable rotational motion while supporting axial, radial, and tilting loads.

Energy Consumption Comparison of WED17

When it comes to energy efficiency, the double worm slewing drive WED17 stands out from the competition. Thanks to its innovative design and advanced manufacturing techniques, the WED17 offers a significantly lower energy consumption compared to traditional single-worm slewing drives. The dual-worm configuration of the WED17 allows for a more efficient transfer of power, reducing the amount of energy required to operate the drive. Additionally, the high-quality components used in the WED17 are designed to minimize friction and wear, further improving its energy efficiency.

In a recent energy consumption comparison test, the WED17 was found to consume up to 30% less energy than a similar-sized single-worm slewing drive. This significant reduction in energy consumption not only helps to lower operating costs but also makes the WED17 a more environmentally friendly choice.

Anti-Micro-Vibration Worm Drive

One of the key features of the double worm slewing drive WED17 is its anti-micro-vibration worm drive. This advanced technology is designed to minimize vibrations and noise during operation, providing a smoother and more stable rotational motion. The anti-micro-vibration worm drive of the WED17 works by using a special damping material that absorbs and dissipates vibrations. This material is integrated into the worm and worm gear, reducing the amount of vibration that is transmitted to the surrounding components.

In addition to reducing vibrations and noise, the anti-micro-vibration worm drive of the WED17 also helps to improve the accuracy and precision of the drive. By minimizing vibrations, the WED17 is able to maintain a more consistent rotational speed, resulting in improved positioning accuracy and repeatability.

Features of the Double Worm Slewing Drive WED17

The double worm slewing drive WED17 offers a wide range of features that make it the ideal choice for a variety of applications. Some of the key features of the WED17 include:

High Output Torque: The dual-worm configuration of the WED17 allows for a more efficient transfer of power, resulting in a high output torque of up to 9.45 kN.m.

High Holding Torque: The WED17 is designed to provide a high holding torque of up to 108.5 kN.m, ensuring that the load remains in place even when the drive is not in operation.

Compact Design: The WED17 features a compact and lightweight design, making it ideal for applications where space is limited.

High Precision: The WED17 is equipped with a high-precision slewing bearing and anti-micro-vibration worm drive, providing smooth and accurate rotational motion.

Robust Construction: The WED17 is built to withstand the toughest operating conditions, with a robust construction and high-quality components.

Easy Installation and Maintenance: The WED17 is designed for easy installation and maintenance, with a simple and straightforward design that requires minimal downtime.

Applications of the Double Worm Slewing Drive WED17

The double worm slewing drive WED17 is a versatile mechanical component that can be used in a wide range of applications. Some of the common applications of the WED17 include:

Industrial Machinery: The WED17 is widely used in industrial machinery, such as cranes, excavators, and conveyors, where high torque and reliability are required.

Aerospace and Defense: The WED17 is also used in aerospace and defense applications, such as satellite tracking systems and missile launchers, where precision and accuracy are critical.

Renewable Energy: The WED17 is an ideal choice for renewable energy applications, such as wind turbines and solar tracking systems, where high torque and energy efficiency are essential.

Medical Equipment: The WED17 is used in medical equipment, such as operating tables and imaging systems, where smooth and precise rotational motion is required.

Automotive Industry: The WED17 is used in the automotive industry, such as in vehicle lifts and robotic arms, where high torque and reliability are needed.

Factors Affecting the Price of the Double Worm Slewing Drive WED17

The price of the double worm slewing drive WED17 can vary depending on a number of factors. Some of the key factors that can affect the price of the WED17 include:

Size and Capacity: The size and capacity of the WED17 can have a significant impact on its price. Larger and more powerful models of the WED17 will generally be more expensive than smaller and less powerful models.

Quality and Materials: The quality and materials used in the construction of the WED17 can also affect its price. Higher-quality components and materials will generally result in a higher price.

Customization: If you require a customized version of the WED17, such as a specific size or configuration, this can also increase the price.

Quantity: The quantity of WED17 units you purchase can also affect the price. Generally, the more units you purchase, the lower the price per unit will be.

Market Conditions: Market conditions, such as supply and demand, can also have an impact on the price of the WED17. If the demand for the WED17 is high and the supply is low, the price may increase.

Supplier of Double Worm Slewing Drives

LYRADRIVE is a leading supplier of high-quality double worm slewing drives, including the WED17. With years of experience in the industry, LYRADRIVE has established a reputation for providing reliable and innovative solutions to its customers. LYRADRIVE's double worm slewing drives are designed and manufactured to the highest standards, using only the best quality materials and components. The company also offers a wide range of customization options, allowing customers to tailor their slewing drives to their specific needs. In addition to its high-quality products, LYRADRIVE also provides excellent customer service, with a team of experienced professionals who are always available to answer any questions or provide support. Whether you are looking for a standard or customized double worm slewing drive, LYRADRIVE has the solution for you.