Typical Uses of Lightweight Slewing Ring Gear Drive SP-I 1091

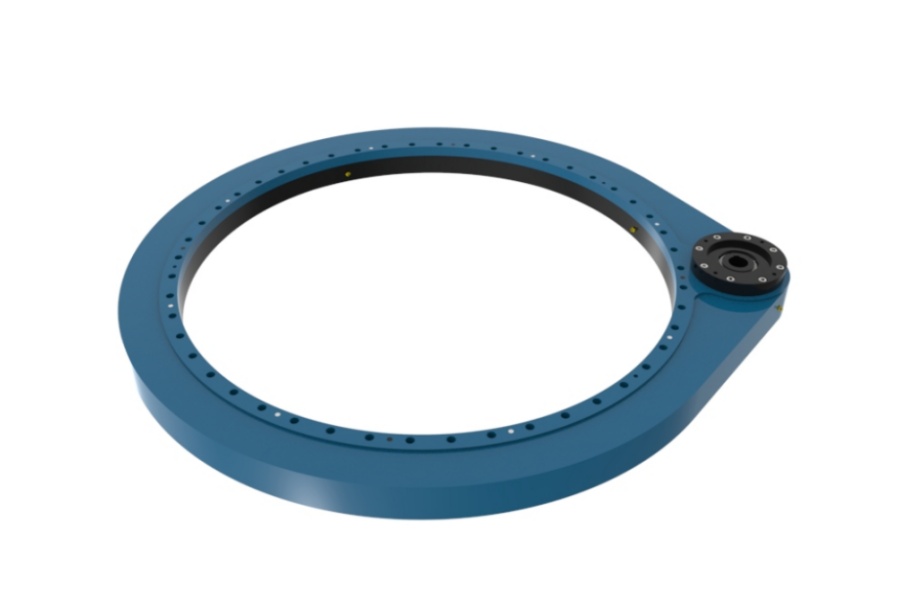

What is Lightweight Slewing Ring Gear Drive SP-I 1091?

Lightweight Slewing Ring Gear Drive SP-I 1091 is an integrated mechanical device that combines a gear-driven reducer with a slewing bearing to enable smooth, precise rotational motion under heavy loads. Engineered with a modular structure, it consists of a gearset (modular 4, 15 pinion teeth, 294 ring teeth), a durable housing, and sealed bearings, delivering a gear ratio of 19.6:1 and a maximum torque of 10,650 N·m. Weighing only 123 kg, it achieves a balance between lightweight design and high load capacity, with radial static load ratings up to 700 kN and axial static loads of 1,860 kN. This makes it suitable for applications where space is limited but performance demands are high.

Analysis of Corrosion Protection Design in Slewing Drives

Corrosion resistance is critical for slewing drives operating in harsh environments. The SP-I 1091 employs multiple strategies to enhance durability:

Material Selection: High-strength alloy steel (e.g., 42CrMo) is used for load-bearing components, offering inherent resistance to corrosion and wear.

Surface Coatings: The housing undergoes electrostatic powder coating with epoxy-zinc-rich primers and topcoats, providing a protective layer against moisture and chemicals. This process ensures a neutral salt spray resistance exceeding 1,000 hours.

Sealing Technology: A double-lip rotary oil seal and IP65-rated enclosure prevent dust and water ingress, maintaining internal lubrication integrity even in outdoor or dusty conditions.

Corrosion-Resistant Fasteners: Stainless steel bolts and corrosion-resistant gaskets are used to avoid galvanic corrosion at joint interfaces.

Energy Consumption Ratio of Lightweight Slewing Ring Gear Drive SP-I 1091

The SP-I 1091 achieves efficient energy transmission through optimized gear geometry and lubrication. With a gear ratio of 19.6:1, it balances torque multiplication and power loss. Key factors influencing its energy consumption include:

Gear Efficiency: The spur gear design minimizes sliding friction, achieving a transmission efficiency of approximately 88–92% under nominal loads.

Lubrication System: Low-viscosity synthetic oils (e.g., ISO VG 220) reduce churning losses, while intelligent lubrication management ensures consistent performance across temperature ranges.

Load-Dependent Efficiency: At maximum torque (10,650 N·m), the drive maintains stable efficiency due to precision gear alignment and minimal backlash.

Motor Compatibility: The drive is compatible with high-efficiency electric or hydraulic motors, further optimizing overall system energy consumption.

Key Features of Lightweight Slewing Ring Gear Drive SP-I 1091

High Torque-to-Weight Ratio: Despite its 123 kg weight, the SP-I 1091 delivers a maximum torque of 10,650 N·m, making it suitable for applications requiring both agility and power.

Compact Design: The integrated gearbox and slewing bearing eliminate the need for external reducers, reducing installation space by up to 30% compared to traditional systems.

Precision Engineering: The gear teeth are hardened to HRC 55–62, ensuring minimal wear and backlash for accurate positioning in robotic or solar tracking systems.

Multi-Load Capacity: It supports radial dynamic loads up to 265 kN and axial dynamic loads of 310 kN, adapting to complex mechanical requirements.

Easy Maintenance: The sealed housing and replaceable seals simplify maintenance, with a service life exceeding 10,000 hours under normal operating conditions.

Applications of Lightweight Slewing Ring Gear Drive SP-I 1091

Solar Tracking Systems: Its lightweight design and high torque enable precise solar panel orientation, maximizing energy capture. The drive’s corrosion resistance ensures reliability in outdoor environments.

Industrial Robotics: Used in robotic arms and automated assembly lines for smooth rotational motion and high positioning accuracy.

Material Handling: Ideal for small cranes and lifting platforms, where its compact size and load capacity enhance maneuverability.

Medical Equipment: Supports rotational movements in imaging systems (e.g., MRI machines) requiring low noise and high precision.

Aerospace and Defense: Utilized in antenna positioning systems and surveillance equipment due to its rugged construction and reliability.

Factors Influencing the Price of Lightweight Slewing Ring Gear Drive SP-I 1091

Material Costs: The use of high-grade alloys (e.g., 42CrMo) and corrosion-resistant coatings directly impacts production expenses.

Manufacturing Complexity: Precision gear cutting, heat treatment, and assembly processes contribute to labor and tooling costs.

Customization Requirements: Specialized designs (e.g., non-standard mounting flanges or encoder integration) increase production time and costs.

Volume Orders: Bulk purchases often result in lower unit costs due to economies of scale.

Market Demand: Fluctuations in supply chain dynamics and raw material prices can affect final pricing.

Supplier of Lightweight Slewing Ring Gear Drive SP-I 1091

LYRADRIVE is a leading manufacturer of slewing drives and bearings, specializing in customized solutions for diverse industries. With over a decade of experience, the company offers comprehensive design, prototyping, and production services, ensuring each Lightweight Slewing Ring Gear Drive SP-I 1091 unit meets rigorous quality standards. Backed by a global network of technical support, LYRADRIVE delivers reliable, high-performance products that empower customers to optimize their mechanical systems.