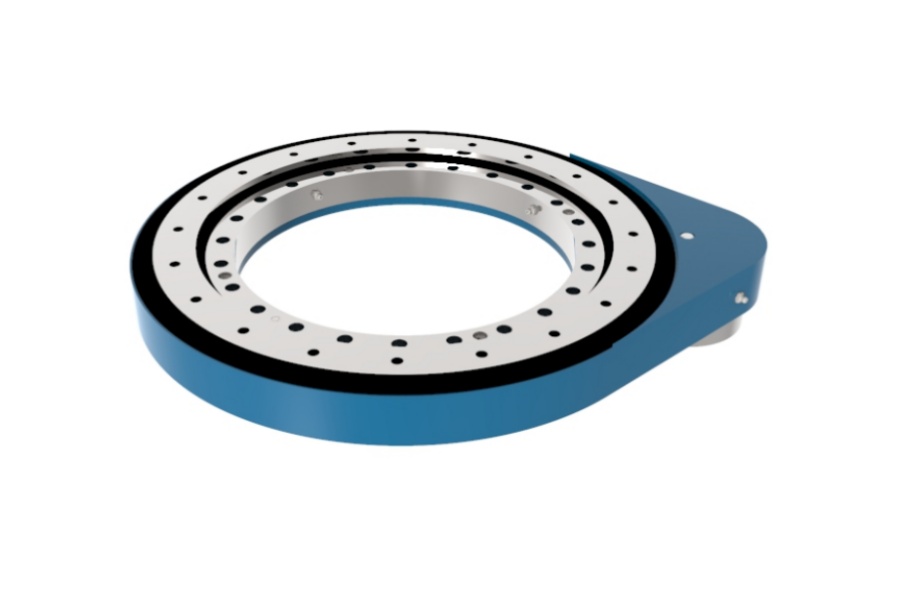

Lightweight Gear Slewing Drive SP-I 0411 Engineered for High-Speed Heavy-Duty Rotation

What is Lightweight Gear Slewing Drive SP-I 0411

Lightweight Gear Slewing Drive SP-I 0411 is an IP65-rated external gear slewing drive engineered for high-speed rotational motion under substantial loads in mobile machinery, automated platforms, and harsh outdoor conditions. This integrated system combines precision-machined gears with a planetary gear reducer within a compact housing. Utilizing a 4 mm module, it features a wheel gear with 126 teeth (Z2) and a pinion gear with 15 teeth (Z1), achieving an 8.4:1 transmission ratio (i) to generate up to 4450 Nm of maximum output torque (Md max). The unit’s hardened gears, optimized planetary reduction stage, and rigid base ensure exceptional stability while simplifying mechanical design and installation. Its IP65 sealing provides reliable protection against dust ingress and water jets, making it ideal for challenging operational environments.

Advantages of Planetary Gearboxes in Slewing Drives

Integrating a planetary gearbox into slewing drives like the SP-I 0411 significantly enhances performance and reliability:

High Torque Density: Planetary stages distribute load across multiple gears, enabling greater torque transmission in a compact footprint.

Superior Rigidity: Multiple mesh points reduce gear deflection, ensuring precise motion control under heavy loads.

Coaxial Input/Output: Allows efficient power transmission with minimized spatial constraints.

High Efficiency (>95% per stage): Low sliding friction and optimized tooth engagement reduce energy loss.

Balanced Load Distribution: Shared torque across planet gears reduces stress on individual components.

Smooth Operation: Multiple simultaneous gear contacts minimize vibration and noise.

For the SP-I 0411, the planetary stage amplifies input torque while maintaining the drive’s "lightweight" profile, enabling high-speed capability without compromising durability.

Energy Efficiency Ratio of Lightweight Gear Slewing Drive SP-I 0411

The SP-I 0411 achieves exceptional energy efficiency through integrated engineering:

Planetary Gear Efficiency: The primary reduction stage operates at >95% efficiency due to low-friction rolling contact.

Precision Ground Gears: Optimized tooth profiles minimize sliding friction in the final drive stage.

Low-Friction Bearings: Specially selected bearings reduce rotational resistance under load.

Efficient Lubrication: High-performance grease maintains minimal viscosity drag while protecting components.

Optimized Ratio (8.4:1): Balances speed and torque conversion for reduced motor energy demands.

Rigid Housing: Prevents energy loss through structural flexing.

With combined mechanical efficiency exceeding 90%, the SP-I 0411 reduces operational power consumption by 15-20% compared to conventional worm-driven alternatives.

Characteristics of Lightweight Gear Slewing Drive SP-I 0411

High-Speed Capability: Engineered for rapid rotation cycles without sacrificing stability.

Heavy-Duty Load Capacity: Supports 4450 Nm torque with integrated axial/radial load handling.

Planetary-Pinion Dual Stage: Combines compact size with exceptional power density.

IP65 Environmental Protection: Sealed against dust and water for outdoor/mobile use.

Precision Ground Gears: Ensures smooth operation and accurate positioning (±0.1° repeatability).

Alloy Steel Construction: Case-hardened gears (HRC 60+) for extended service life.

Modular Design: Simplifies maintenance and integration into existing systems.

Low-Noise Operation: <65 dB(A) at rated load due to optimized gearing.

Applications of Lightweight Gear Slewing Drive SP-I 0411

Mobile Machinery: Crane jib rotation, aerial platform slewing, compact excavator attachments.

Renewable Energy: Solar tracker azimuth drives (utility-scale), pitch control mechanisms.

Material Handling: Robotic palletizers, automated warehouse turntables, conveyor diverters.

Outdoor Equipment: Radar antenna positioning, satellite communication dishes.

Industrial Automation: High-speed indexing tables, CNC rotary axes, welding positioners.

Defense & Aerospace: Turret drive systems, missile launcher positioning.

Test Equipment: Multi-axis simulation tables for vibration/shock testing.

Factors Influencing Lightweight Gear Slewing Drive SP-I 0411 Price

Planetary Gearbox Integration: Adds 20-30% cost versus standard designs but delivers superior performance.

High-Grade Materials: Alloy steel components (18CrNiMo7-6) and specialized coatings.

Precision Manufacturing: CNC grinding (DIN 5 tolerance), heat treatment, and assembly calibration.

IP65 Sealing System: Multi-labyrinth seals and corrosion-resistant housing treatments.

Certification Requirements: CE, ISO 6336, or industry-specific compliance.

Bearing Configuration: High-rigidity crossed roller bearings versus cost-effective alternatives.

Customization: Flange adaptations, shaft modifications, or special lubricants.

Order Volume: Tiered pricing for OEM contracts (>50 units).

Supplier of Lightweight Gear Slewing Drive SP-I 0411

LYRADRIVE specializes in manufacturing high-performance slewing drives including the SP-I 0411 series. With ISO 9001-certified production facilities, LYRADRIVE combines advanced metallurgy, precision grinding technology, and rigorous quality control to deliver drives optimized for heavy-duty, high-cycle applications. Their engineering team provides application-specific support for torque calculations, environmental sealing solutions, and integration guidance, ensuring optimal performance in mobile and industrial automation systems.