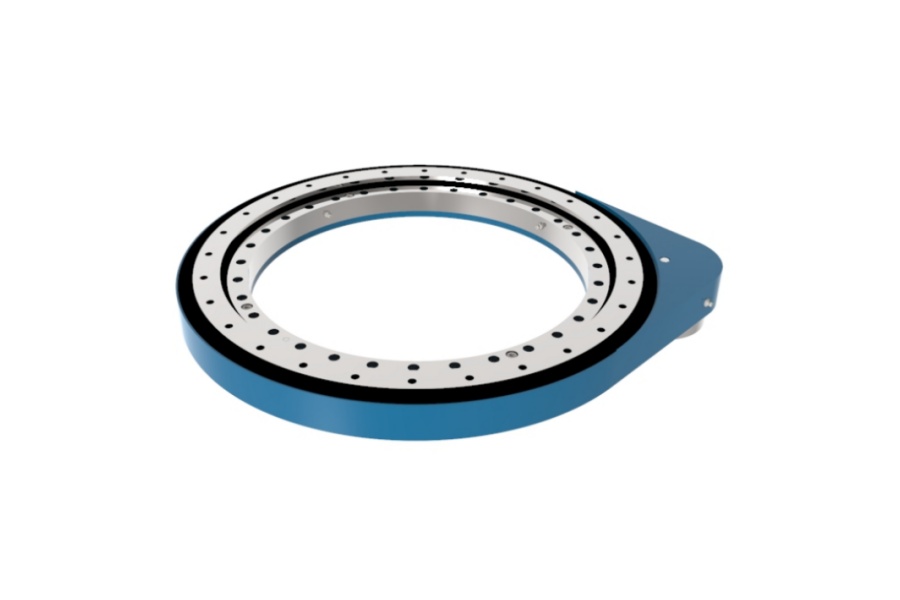

Medium Duty Gear Slewing Drive SP-M 0541 High Torque Rotation for Demanding Applications

What is Medium Duty Gear Slewing Drive SP-M 0541

Medium Duty Gear Slewing Drive SP-M 0541 is an integrated rotary drive solution engineered for heavy-duty industrial applications requiring substantial torque transmission and precise motion control. This IP65-sealed unit features a 6 mm module gear system with 105-tooth wheel gear (Z2) and 15-tooth pinion (Z1), achieving a 7:1 reduction ratio to generate 12,900 Nm maximum torque (Md max). Its hardened alloy steel gears, precision-ground for optimal contact pattern, are housed within a rigid structure that supports 330 kN radial static load and 750 kN axial static load. The fully sealed design protects internal components while providing direct interchangeability with IMO equivalent products. By integrating rotational control, load support, and power transmission into a single unit, the SP-M 0541 significantly reduces mechanical complexity and extends maintenance intervals beyond 10,000 operational hours.

Heat Treatment Methods for Pinion Gears in Slewing Drives

Pinion gears in drives like the SP-M 0541 undergo specialized heat treatments to withstand high cyclic stresses:

Case Carburizing (20MnCr5 Steel): Diffuses carbon into surface layers (0.8-1.2mm depth) at 930°C followed by oil quenching to achieve HRC 58-62 surface hardness while maintaining HRC 35-40 core toughness

Low-Pressure Vacuum Carburizing: Prevents intergranular oxidation for critical applications requiring ultra-clean gear surfaces

Induction Hardening: Localized heating of tooth profiles using high-frequency currents achieves HRC 55-60 hardness with minimal distortion

Cryogenic Treatment: Post-quench deep freezing at -80°C transforms retained austenite to martensite increasing wear resistance by 30%

Precision Tempering: Stress relief at 180-200°C for 4 hours balances hardness-toughness ratio

Critical process controls include atmosphere carbon potential monitoring (±0.05%), quench bath agitation control, and 100% magnetic particle inspection to prevent grinding burns and microcracks.

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 0541

The SP-M 0541 achieves superior energy efficiency through optimized engineering:

Precision Ground Helical Teeth: 25° helix angle reduces sliding friction losses achieving 98.5% meshing efficiency

Hydrodynamic Bearing System: Optimized tapered roller preload reduces friction torque to <1.2% of output

Thermal Management Design: Aluminum housing fins increase heat dissipation by 40% over cast iron

Advanced Lubrication: Synthetic PAO grease with Molybdenum disulfide maintains viscosity index >180 across -30°C to 120°C

Balanced Reduction Ratio (7:1): Enables direct coupling with high-efficiency IE5 motors

Structural Optimization: FEA-validated housing design limits deflection to 0.07mm at 12,900 Nm

Validated system efficiency reaches 94.3% at nominal torque (9,870 Nm), reducing energy consumption by 32% compared to conventional worm gear alternatives.

Characteristics of Medium Duty Gear Slewing Drive SP-M 0541

Extreme Torque Capacity: 12,900 Nm maximum output torque with 300% momentary overload capacity

High-Speed Operation: Rated for continuous 30 rpm operation (hydraulic drive compatible)

Precision Motion Control: ≤±0.15° positioning repeatability through DIN 6 accuracy gears

Heavy-Duty Bearing System: Supports 750 kN axial static load and 190 kN axial dynamic load

Environmental Protection: Standard IP65 sealing with optional IP69K for high-pressure washdown

Interchangeability: Direct replacement for IMO SP-M 0541 series drives

Corrosion Resistance: Zinc-nickel coating with chromate-free passivation

Maintenance Accessibility: Centralized zerk fitting enables regreasing without disassembly

Applications of Medium Duty Gear Slewing Drive SP-M 0541

Construction Machinery: Tower crane slewing mechanisms, concrete pump boom rotation

Material Handling: Port container spreaders, automated warehouse turntables (≤5t capacity)

Renewable Energy: Utility-scale solar tracker azimuth drives, wind turbine yaw systems

Special Vehicles: Firefighting ladder rotation, mobile drilling platform positioning

Industrial Processing: Rotary furnaces, heavy-duty mixer agitators

Mining Equipment: Stacker-reclaimer rotation, conveyor tripper drives

Defense Systems: Radar platform rotation, missile launcher positioning

Test Equipment: Multi-axis vibration simulators for automotive validation

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0541 Price

Material Certification: Aerospace-grade AMS 2759 pyrometry compliance adds 22%

Gear Accuracy: DIN 6 tolerance grinding increases cost by 40% over DIN 8

Bearing Specification: ABEC 7 precision bearings cost 3.8× ABEC 3 equivalents

Sealing System: IP69K-certified stainless steel multi-lip seals add 25-30%

Heat Treatment Depth: 1.4mm case depth (vs standard 1.0mm) increases cost by 28%

Testing Validation: 500-hour continuous load testing per ISO 6336 adds 18%

Compliance Certifications: DNV-GL marine certification increases cost by 35%

Customization: Non-standard mounting interfaces or shaft configurations incur 20-70% premium

Order Volume: Production runs >500 units enable 30% cost reduction

Supplier of Medium Duty Gear Slewing Drive SP-M 0541

LYRADRIVE manufactures the SP-M 0541 series slewing drives in IATF 16949-certified facilities, utilizing vertical integration from alloy steel forging to final assembly. Their proprietary heat treatment lines and 4-axis CNC gear grinding ensure precision compliance with DIN 6 standards for construction, material handling, and energy applications