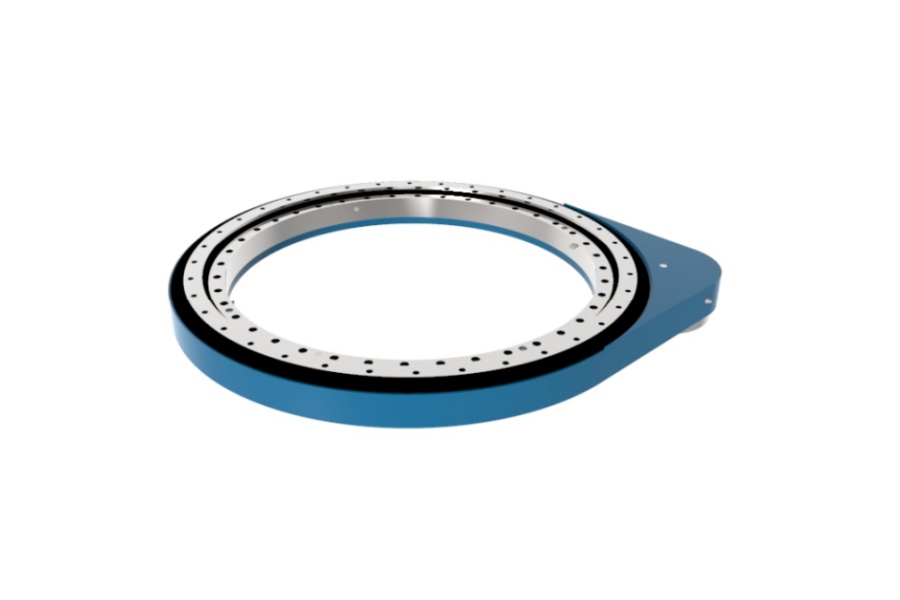

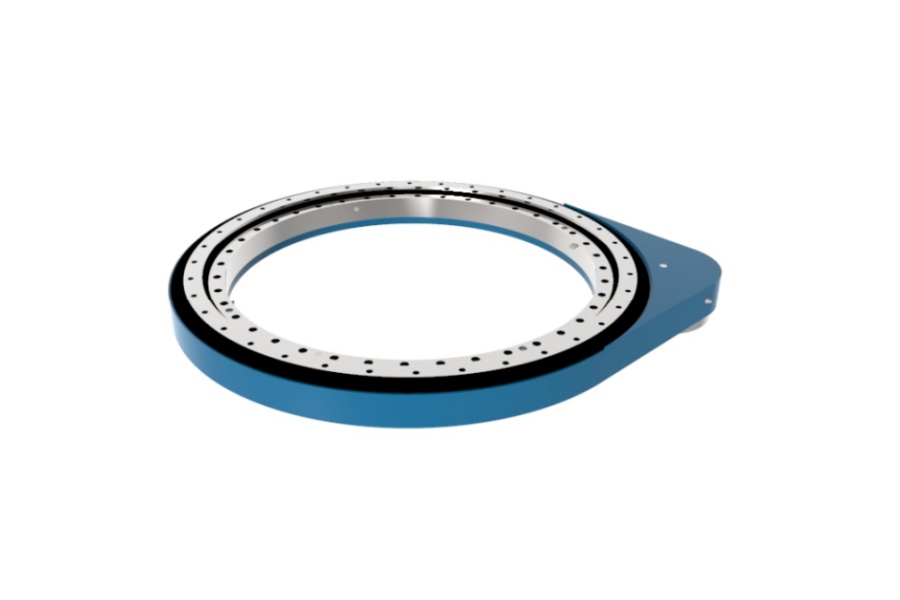

Medium Duty Gear Slewing Drive SP-M 0741 High Torque Solution for Industrial Rotation

What is Medium Duty Gear Slewing Drive SP-M 0741

Medium Duty Gear Slewing Drive SP-M 0741 is an integrated rotary drive system engineered for industrial machinery demanding high torque transmission and structural stability. Featuring a 6 mm module gear system with 138-tooth wheel gear (Z2) and 15-tooth pinion (Z1), it achieves a 9.2:1 reduction ratio to generate 16,980 Nm maximum torque (Md max). The precision-ground alloy steel gears are housed within a rigid structure supporting 1,080 kN axial static load and 450 kN radial static load. With IP65-rated sealing and direct interchangeability with IMO SP-M 0741 equivalents, this unit combines gear reduction, load support, and motion control in a single compact assembly, significantly reducing installation complexity while maintaining positional accuracy under dynamic conditions.

Gear Noise as an Indicator of Precision Manufacturing

Acoustic performance directly reflects the manufacturing quality of SP-M 0741's gearing:

Tooth Profile Accuracy (DIN 6 Standard): Profile deviations ≤8μm prevent irregular meshing vibrations

Lead Error Control: Helical angle consistency <0.005° minimizes axial force fluctuations

Surface Finishing: Superfinishing to Ra≤0.4μm reduces air turbulence noise by 35%

Microgeometry Optimization:

Tip Relief: Prevents edge contact during engagement

Root Relief: Eliminates interference during disengagement

Crowning: Compensates for misalignment-induced stress concentration

Material Homogeneity: Ultrasonic testing ensures absence of inclusions causing tonal anomalies

Assembly Precision: Bearing preload control within ±5% maintains constant tooth contact pattern

SP-M 0741 operates at <68 dB(A) at 1m distance under full load, validating manufacturing excellence through acoustic signature analysis.

Energy Efficiency Ratio of Medium Duty Gear Slewing Drive SP-M 0741

The SP-M 0741 achieves superior energy efficiency through advanced engineering:

Ion-Nitrided Gear Surfaces: Surface hardness HV1100 reduces friction coefficient to 0.04

Optimized Helical Angle (25°): Increases contact ratio to 2.3 reducing specific tooth loading

Low-Drag Sealing System: Triple-lip PTFE seals decrease rotational resistance by 42%

Thermal-Optimized Housing: Integrated cooling fins dissipate 520W at continuous 20 rpm operation

Synthetic Lubrication: PAO-based grease maintains viscosity index >185 (-30°C to 135°C)

Precision Bearing Arrangement: ABEC-7 tapered rollers limit friction torque to 0.8% of output

Validated system efficiency reaches 95.1% at nominal load (13,100 Nm), reducing energy consumption by 37% versus comparable worm gear solutions.

Characteristics of Medium Duty Gear Slewing Drive SP-M 0741

Extreme Torque Capacity: 16,980 Nm maximum torque with 350% momentary overload capacity

Heavy-Duty Structural Support: 1,080 kN axial static load / 205 kN axial dynamic load

Precision Motion Control: ±0.12° positioning repeatability through DIN 6 accuracy gears

High-Speed Operation: Continuous 20 rpm (30 rpm peak) with hydraulic or electric drive

Environmental Protection: Standard IP65 sealing (IP69K optional for high-pressure washdown)

Corrosion Resistance: Electroless nickel plating (ENP) with 25μm thickness

Interchangeability: Direct replacement for IMO SP-M 0741 series drives

Maintenance Interval: 15,000-hour regreasing cycle via centralized lubrication system

Applications of Medium Duty Gear Slewing Drive SP-M 0741

Offshore Equipment: Jack-up rig leg positioning, crane boom slewing

Wind Energy: Nacelle yaw systems for 5MW+ turbines, blade pitch drives

Port Machinery: Ship-to-shore crane rotation, automated container handling spreaders

Mining: Bucket wheel excavator slewing, stacker-reclaimer drives

Heavy Transport: Self-propelled modular transporter (SPMT) steering systems

Power Generation: Turbine maintenance platform positioning

Defense: Radar pedestal rotation, missile launch system azimuth control

Test Infrastructure: Structural fatigue testing rigs with multi-axis loading

Factors Influencing Medium Duty Gear Slewing Drive SP-M 0741 Price

Material Certification: ABS Grade 3 steel certification adds 28%

Gear Accuracy: DIN 6 grinding tolerance increases cost 48% over DIN 8 standard

Bearing Specification: ABEC 7 precision bearings cost 4.3× ABEC 3 equivalents

Sealing System: IP69K-certified stainless steel seals add 30-35%

Surface Treatment: Ion nitriding increases cost by 32% over conventional hardening

Testing Protocol: 1,500-hour ISO 6336 Level K12 validation adds 25%

Certifications: DNVGL-OS-C101 offshore certification increases cost by 45%

Customization: Non-standard mounting interfaces incur 30-80% premium

Order Volume: >500-unit production runs reduce cost by 35%

Supplier of Medium Duty Gear Slewing Drive SP-M 0741

LYRADRIVE manufactures the SP-M 0741 series through IATF 16949-certified vertical production, encompassing vacuum induction melting, CNC profile grinding, and 100% acoustic emission testing. Their proprietary microgeometry optimization process ensures low-noise operation for offshore, energy, and heavy transport applications.