Material selection for Slewing Bearing Components

What is Slewing Bearing?

Imagine a large, precision-engineered "turntable" that is engineered to handle immense weight while allowing smooth, controlled rotation. This is a slewing bearing. Unlike standard small ball bearings, slewing bearings are robust, integrated assemblies designed to support complex combinations of axial, radial, and moment (tilting) loads. They are the fundamental rotational joint in heavy machinery, enabling everything from wind turbines to swing cranes, excavators, and medical scanners to pivot precisely and reliably. Their design combines a bearing and a gear into one compact unit, making them a critical power-transmission component in countless industrial and mobile applications.

How Does a Slewing Bearing Work?

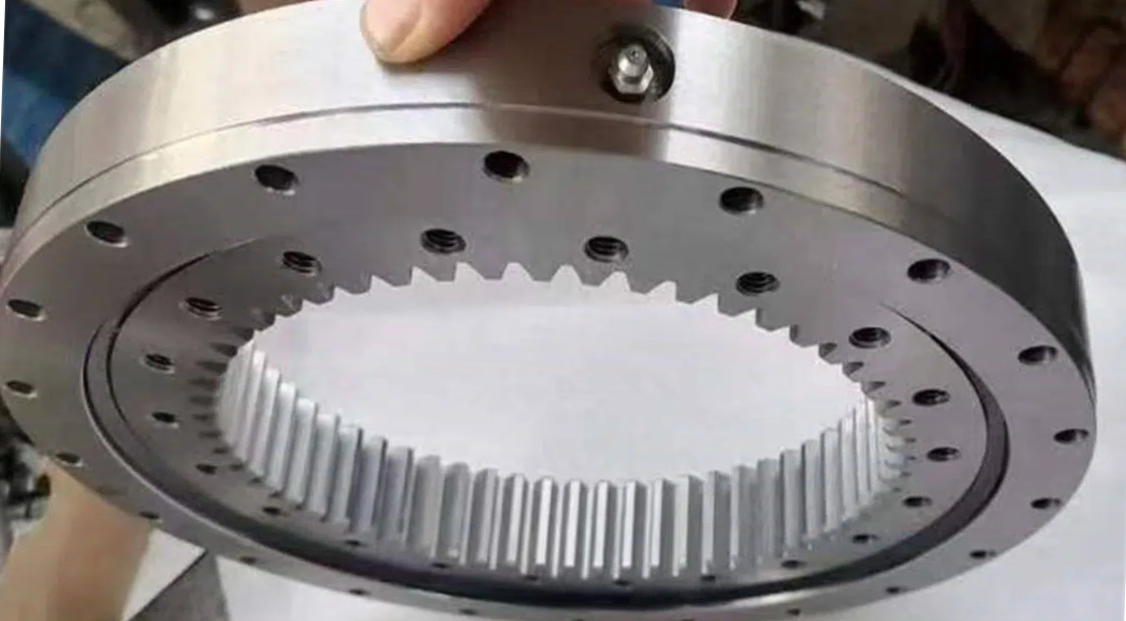

A slewing bearing operates on a deceptively simple principle. At its core, it consists of an inner ring and an outer ring, with precisely engineered rolling elements (balls or cylindrical rollers) running in hardened raceways (grooves) between them. One ring is typically fixed to a base structure, while the other rotates. The integrated gear teeth, machined either on the inner or outer ring, mesh with a smaller pinion gear driven by a motor. When the motor turns the pinion, it drives the geared ring, causing the entire upper structure to rotate. The rolling elements bear the heavy loads, minimizing friction and ensuring smooth, stable movement under tremendous stress.

Key Components of a Slewing Bearing

Understanding the function of each part is key to appreciating slewing bearing design and material science.

Inner Ring & Outer Ring (Raceways): These are the main structural components. They contain the precisely machined grooves (raceways) where the rolling elements travel. Their strength and surface hardness are paramount for bearing life.

Rolling Elements: These are the load-carrying components that roll between the raceways. They come primarily as balls (for higher speed, lower friction) or rollers (for higher load capacity). Their material and precision directly impact performance.

Gear Teeth: Integral to the inner or outer ring, these teeth transfer rotational force from the drive pinion. They must withstand constant meshing forces without wear or deformation.

Seals: Essential for longevity, seals are flexible lips (usually rubber) mounted in grooves. They form a barrier that keeps lubricating grease inside and prevents contaminants like dust, water, and abrasive particles from entering the bearing raceways.

Isolators/Spacers: These components separate the rolling elements, preventing them from contacting and wearing against each other, ensuring even load distribution.

Lubrication Fittings: These small but vital ports allow for the injection of fresh grease during routine maintenance to replenish lubrication and displace contaminants.

Materials Used in Slewing Bearing Components: A Component-by-Component Deep Dive

The exceptional performance of a slewing bearing is a direct result of the precise material selection for each of its components. The choice is never arbitrary; it is a targeted engineering decision where the material properties are meticulously matched to the specific mechanical, thermal, and environmental demands each part faces. Below is a detailed analysis of why specific materials are chosen for key components.

1. Inner & Outer Rings (Raceways) – The Structural Foundation

Primary Materials: Forged 50Mn or 42CrMo Alloy Steel are the industry standards.

Material Rationale & Considerations:

The rings are the backbone, bearing the full spectrum of loads. 50Mn steel offers an excellent cost-to-performance ratio with good hardenability and strength, suitable for many general applications. For more demanding conditions involving higher dynamic loads, shock, or heavy moment loads, 42CrMo is preferred. The addition of chromium (Cr) and molybdenum (Mo) enhances its hardening depth, core toughness, and fatigue resistance.

The critical process is surface hardening via induction hardening or carburizing. This creates an extremely hard surface layer (55-62 HRC) to resist wear and rolling contact fatigue, while the softer, ductile core absorbs impacts and prevents brittle fracture. Selection factors include: load magnitude/type (static vs. dynamic, moment loads), required hardening depth to withstand subsurface shear stresses, and operating environment (corrosion may require plating or a shift to stainless steel).2. Rolling Elements (Balls/Rollers) – The Precision Load Carriers

Primary Material: GCr15 / AISI 52100 High-Carbon Chromium Bearing Steel.

Material Rationale & Considerations:

Rolling elements are subjected to extremely high, repetitive Hertzian contact stresses. GCr15 steel is engineered specifically for this purpose. Its high carbon content ensures it can achieve a very high (60-66 HRC) and uniform through-hardness after heat treatment. The key is microstructural homogeneity and cleanliness—internal inclusions or soft spots act as stress concentrators, initiating premature spalling and fatigue failure.

Through-hardening (as opposed to surface hardening) is essential to ensure that every point within the ball or roller possesses the same high resistance to deformation, regardless of the contact angle. The primary selection factor is the calculated contact stress and required L10 fatigue life. The material's purity, hardness consistency, and geometric precision (sphericity or cylindricity) are paramount.3. Gear Teeth – The Power Transmission Interface

Primary Material: Typically the same case-hardened alloy steel (e.g., 42CrMo) as the ring it is integrated with.

Material Rationale & Considerations:

Gear teeth endure cyclical bending stress and surface wear from meshing with the pinion. Case hardening (carburizing) is the ideal process here. It creates a deep, hard, wear-resistant surface (58-62 HRC) to prevent pitting and abrasion, while maintaining a tough, ductile core (typically 30-40 HRC) that can withstand the root bending stresses and absorb shock loads without tooth fracture.

The material selection and heat treatment process must balance surface hardness for wear resistance with core toughness for impact resistance. Considerations include: transmitted torque, presence of shock loads, required gear precision (which influences post-heat-treatment machining like grinding), and compatibility with the mating pinion's hardness to ensure proper wear-in without galling.4. Seals – The Environmental Defense System

Primary Materials: Nitrile Rubber (NBR), Polyurethane (PU), Fluorocarbon (FKM/Viton).

Material Rationale & Considerations:

Seals must remain flexible and resilient to exclude contaminants and retain grease. The choice is almost entirely driven by the operating environment and temperature.NBR is the standard, offering good resistance to lubricants, water, and a broad temperature range (-40°C to +120°C).

For environments with abrasives (dust, sand), PU offers superior cut and tear resistance.

In the presence of chemicals, fuels, or for continuous high-temperature operation, FKM (Viton) is necessary for its exceptional chemical and thermal stability (up to 200°C+).

The selection is a function of: contaminant type (dust, water, chemical), temperature range, and required seal lip friction against the ring.5. Isolators/Spacers – The Rolling Element Organizers

Primary Materials: Sheet Steel, Polyamide (Nylon 6/6), Brass, or Engineered Polymers.

Material Rationale & Considerations:

Isolators prevent rolling element contact, reduce friction, and guide movement. The choice balances strength, friction, and environmental needs.Steel or Brass Isolators are used in high-speed, high-temperature, or heavily loaded applications where mechanical strength and dimensional stability are critical. They are more durable but may require additional lubrication.

Polyamide (Nylon) Isolators are most common, providing excellent wear resistance, low friction, and corrosion immunity. They are lightweight and can operate with minimal lubrication. Selection factors include: cage pocket stress, operating speed (centrifugal force), temperature limits of the polymer, and lubrication regime.

In summary, selecting materials for a slewing bearing is a holistic, component-specific engineering task. It requires a deep understanding of the functional role, stress state, failure modes, and environmental exposure of each part to specify the material and process combination that delivers optimal performance, reliability, and lifetime value.

How to Select Materials for Slewing Bearing Components?

Selecting the optimal material is a multi-faceted engineering decision. Here are the key factors:

1. Analyze the Load Profile and Duty Cycle

Load Magnitude & Type: Higher dynamic loads or heavy moment loads demand higher-grade alloy steels (like 42CrMo over 50Mn) with superior core properties.

Operational Cycles: Bearings in continuous 24/7 operation (e.g., in a wind turbine) require materials with exceptional fatigue life, often justifying premium steel grades and stringent cleanliness standards to prevent early failure from inclusions.

2. Assess the Operating Environment

This is often the decisive factor.

Corrosion: Marine, offshore, or chemically exposed applications mandate stainless steel or comprehensively coated carbon steel. The coating must be robust enough to withstand handling and potential scratch damage.

Temperature Extremes: For arctic operations, materials like 34CrNiMo6 are selected for superior low-temperature impact toughness. High-temperature environments require stable steels and compatible seals (FKM).

Contamination: Environments with dust, sand, or slurry require a focus on high-performance seal systems (often multi-labyrinth designs) to protect the raceways, making the seal material choice as critical as the steel.

3. Evaluate Gear Performance Requirements

High Torque & Precision: Applications requiring precise positioning and high drive torque need fine-grained, homogenous steels that allow for precision gear grinding after heat treatment to achieve low backlash and smooth operation.

Gear Hardness: The gear surface hardness must be carefully matched to the mating pinion to ensure proper wear characteristics and prevent premature pitting.

4. Optimize for Total Cost of Ownership (TCO)

The goal is to select the material that provides the necessary performance and lifespan at the lowest overall cost. This involves:

Avoiding Over-specification: Using marine-grade stainless steel for a clean, indoor application is unnecessarily expensive.

Preventing Under-specification: Using a standard carbon steel in a corrosive environment leads to premature failure, causing costly downtime and replacement, far exceeding the initial savings.

A simplified decision matrix can guide this process:

| Key Consideration | Standard/General Purpose | Heavy-Duty/High-Cycle | Corrosive Environment | Extreme Temperature |

|---|---|---|---|---|

| Ring Material | 50Mn Steel | 42CrMo or Similar Alloy Steel | Stainless Steel (e.g., 304/316) / Coated Steel | Low-Temp Alloy Steel (e.g., 34CrNiMo6) |

| Heat Treatment | Induction Hardening | Case Hardening (Carburizing) | Case Hardening + Coating | Appropriate hardening for material |

| Seal Material | Nitrile Rubber (NBR) | NBR or FKM for reliability | FKM (Chemical Resistant) | Silicone (VMQ) or FKM |

Advanced and Custom Material Solutions by LyraDrive

At LyraDrive, we provide more than just standard components; we deliver engineered material solutions. As a professional one-stop slewing device manufacturer with over 15 years of deep expertise in the design, development, and customized production of slewing bearings and slew drives, we partner with our clients to solve their most challenging application problems.

Our experience across our SE slew drive, WE slew drive, WED slew drive has given us unparalleled insight into material performance under real-world conditions. We don't just offer a catalog—we engage in a consultative process:

Application Analysis: We work with you to fully understand the load dynamics, environmental hazards, and life expectancy requirements.

Material Specification: Based on this analysis, we specify the optimal material grade, heat treatment process, and protective coatings. Whether it's a special alloy for sub-arctic toughness, a customized plating for salt spray resistance, or a unique seal compound for a chemical washdown, we have the expertise to source and apply it.

Total Solution Provider: From the initial design of a custom slewing bearing to the manufacture of a high-performance slew drive, our team ensures every material choice is made to maximize reliability, durability, and value for your specific application.

FAQ on Slewing Bearing Materials

The following questions address the most common and critical inquiries we receive at LyraDrive regarding how material choices directly impact the performance, longevity, and suitability of slewing bearings for specific applications.

Q1: For the bearing rings, when should we choose 50Mn steel over 42CrMo, and vice versa?

This is a fundamental choice based on load dynamics and required core toughness. 50Mn steel is an excellent, cost-effective general-purpose material suitable for applications with predominantly static or moderately dynamic loads and standard duty cycles. Choose 42CrMo alloy steel when your application involves high dynamic loads, significant shock loads, heavy tilting moments, or requires a very high fatigue life. The chromium and molybdenum in 42CrMo provide superior hardenability depth and core toughness, making it the choice for demanding conditions in heavy construction, mining, or intensive industrial automation.

Q2: Why is the rolling element material almost always GCr15 (52100) steel? Can other materials be used?

GCr15 bearing steel is specified because its properties are uniquely suited to withstand rolling contact fatigue—the primary failure mode for balls and rollers. It achieves a very high, uniform through-hardness (60-66 HRC) that is consistent from surface to core, which is critical as stress is distributed below the surface. While other materials like stainless steel (440C) can be used for corrosion resistance, they typically have lower load ratings for the same size. The choice is a balance: GCr15 for maximum load capacity and fatigue life; alternatives are chosen only when the operating environment (like severe corrosion) makes the trade-off necessary.

Q3: Our application is in a highly corrosive seaside environment. What are our best material options?

For corrosive environments, material strategy involves both the base metal and surface protection:

First Option – Coated Carbon Steel: For most marine and offshore applications, using high-strength alloy steel rings (42CrMo) with a high-performance anti-corrosion coating like zinc-nickel plating or Dacromet is the optimal balance of strength, durability, and cost. This protects the structural component while maintaining full load capacity.

Second Option – Stainless Steel: If the equipment requires washdowns with chemicals or must meet strict hygiene standards (e.g., food processing), austenitic stainless steels like AISI 304 or 316 are necessary. It is crucial to note that switching to stainless steel affects the hardening process and may require a slight increase in bearing size to achieve an equivalent load rating due to different material mechanics.

Q4: How does the operating temperature range affect our choice of seal and isolator materials?

Temperature is a primary driver for polymer component selection:

Seals: Standard Nitrile (NBR) seals perform well from -40°C to +120°C. For sustained high temperatures above 120°C (e.g., near furnaces, on certain heavy machinery), Fluorocarbon (FKM/Viton) is required. For consistently low temperatures below -40°C, Silicone (VMQ) rubber may be specified for its retained flexibility.

Isolators (Spacers): Standard polyamide (nylon) isolators have a temperature limit, typically around 120°C. In high-temperature applications beyond this limit, metal isolators (brass or steel) must be used to maintain dimensional stability and prevent failure.

Q5: We have a high-precision, low-backlash application. How do material choices for the gear teeth influence this?

Achieving and maintaining high gear precision is heavily dependent on material and processing:

Material & Process: Case-hardened alloy steels (e.g., 42CrMo) are essential. The carburizing process creates a hard, wear-resistant tooth surface while preserving a tough core.

Post-Hardening Machining: The key to low backlash is the ability to precision grind the gear teeth after the heat treatment. The selected steel must have stable, predictable behavior during hardening to minimize distortion, allowing for efficient and accurate final grinding. This ensures the gear meets tight tolerances for tooth profile and lead, which directly translates to smooth operation, precise positioning, and minimal backlash over the bearing's life.