How to Select the Backlash for Slew Drives?

What is Slew Drive?

A slew drive, also known as a slewing drive, is a compact, high-efficiency power transmission component. It integrates a slewing bearing with a precision gearbox (typically featuring a worm gear mechanism) into a single, robust unit. This design enables it to handle simultaneous axial, radial, and moment loads while providing high reduction ratios for smooth, controlled rotational motion. Its compact, sealed, and all-in-one structure makes it a fundamental building block for machinery requiring precise and powerful rotation.

How Does Slew Drive Work?

The core principle of a slew drive is based on the worm gear mechanism. When the input shaft, connected to the motor, rotates the worm (a threaded screw), it engages with and drives the worm wheel (a gear integrated into the slewing bearing's outer ring or inner ring). This engagement converts the high-speed input from the motor into a powerful, low-speed, high-torque output rotation of the bearing ring. A key feature is its ability to achieve self-locking under certain gear ratios, preventing back-driving and holding the load securely in position without the need for an external brake.

Application of Slew Drive

Slew drives are incredibly versatile and are the backbone of motion in many industries. Common applications include:

Solar Tracking Systems: Precisely positioning solar panels to follow the sun's path.

Wind Turbines: Adjusting the pitch of blades for optimal wind capture and control.

Construction Machinery: Enabling the rotation of excavator booms, crane booms, and man-lifts.

Material Handling: Powering the rotation of robotic arms, stackers, and palletizers.

Satellite & Radar Antennas: Providing accurate and stable rotational positioning for communication and surveillance equipment.

What is Backlash in Slew Drives?

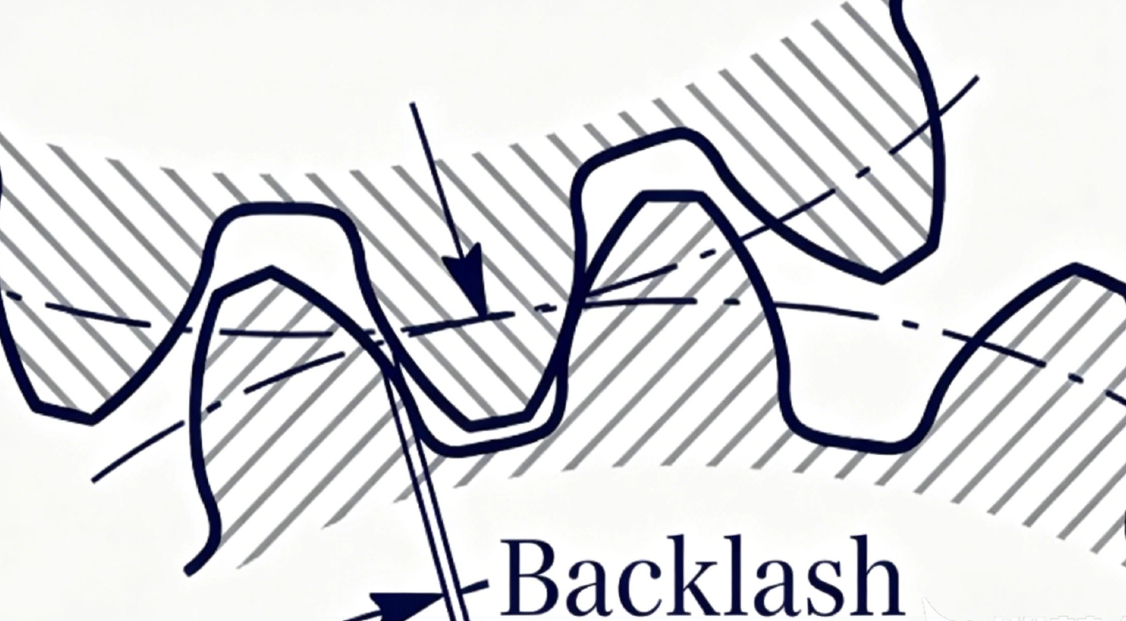

In simple terms, backlash is the slight, measurable movement or "play" in the drive system when you reverse the rotation direction. Imagine gently rocking a gear back and forth—the tiny free movement before it engages the other side is backlash.

In a slew drive, this play comes from the clearance between the meshing teeth of the worm (or pinion) and the gear on the slewing bearing, as well as internal bearing clearance. It is not a defect but a deliberate design parameter. Zero backlash is neither practical nor desirable for most heavy-duty applications, as it would cause excessive friction, heat, and rapid wear.

Types of Backlash in Slew Drives

Backlash is generally categorized by its measurement and intended performance level:

Standard Backlash: This is the most common grade, offering a good balance between cost, efficiency, and smooth operation. It is suitable for applications where extreme precision is not the primary concern, such as in material handling or solar trackers.

Precision (Low) Backlash: This involves tighter manufacturing tolerances to minimize free play. It is essential for applications requiring accurate positioning and repeatability, such as radar antennas, robotic arms, or advanced automation equipment.

Special/Adjustable Backlash: Some high-end slew drive designs allow for backlash adjustment during service life to compensate for wear or to fine-tune performance for specific operational phases.

Key Factors to Consider When Selecting Backlash

Choosing the right backlash for your slew drive involves balancing multiple factors to ensure performance, durability, and cost efficiency. Here are the key considerations:

1. Application Precision Requirements

Do you need high positional accuracy, such as in robotic arms or radar systems? If so, low backlash is essential. For less precise tasks like material handling, standard backlash is often sufficient.

2. Load Characteristics and Torque

The type and magnitude of loads directly affect backlash selection:

Shock Loads: Applications with sudden impacts (e.g., mining equipment) benefit from slightly higher backlash, which acts as a cushion to protect gear teeth.

Continuous High Torque: Under heavy torque, gear teeth may experience slight deflection. Adequate backlash prevents binding and ensures smooth operation.

3. Operating Temperature Range

Temperature changes significantly impact backlash:

Low Temperatures: Lubricants thicken, and metal contracts, potentially reducing backlash and increasing friction. Applications in cold environments may need slightly higher initial backlash.

High Temperatures: Metals expand, and lubricants thin out, potentially increasing backlash. In hot conditions, tighter backlash may be specified to compensate for thermal expansion.

4. Lubrication and Contamination

Lubrication Quality: Proper lubrication minimizes wear and maintains stable backlash over time. Inadequate lubrication accelerates wear, leading to rapid backlash increase.

Contamination: In dusty, wet, or corrosive environments (e.g., construction sites, marine applications), seals and lubrication are critical. Contamination can cause abrasive wear, increasing backlash unpredictably. For harsh environments, robust sealing and more frequent maintenance are essential, and slightly larger backlash may be tolerated to account for faster wear.

5. Operational Speed and Motion Profile

Slow-Speed, High-Torque Applications: Most slew drives operate at low speeds, where standard backlash is adequate.

Rapid Reversals or High-Speed Indexing: These require lower backlash to maintain stability and positioning accuracy.

6. Cost and Longevity Trade-offs

Precision (Low Backlash): Requires tighter tolerances, higher-quality materials, and more rigorous assembly, increasing cost.

Standard Backlash: More cost-effective and suitable for most industrial applications.

7. System Stiffness and Elastic Deformation

Under heavy loads, the housing, gears, and bearings may deform slightly. This elastic deformation can temporarily reduce backlash during operation. Engineering calculations should account for this to avoid zero-backlash conditions under load.

Application-Based Backlash Selection for Slew Drives

Here’s how backlash selection translates to real-world uses:

High-Precision Applications (Low Backlash):

Military & Aerospace: Radar systems, satellite communication dishes, missile launchers.

Industrial Automation: Robotic welding cells, precision indexing tables, CNC tool changers.

Medical Imaging: CT scanner gantries.

General Industrial Applications (Standard Backlash):

Construction Machinery: Excavators, mobile cranes, concrete pump booms.

Renewable Energy: Solar tracking systems, wind turbine yaw drives.

Material Handling: Stackers, rotators, and heavy-duty turntables.

High-Load, High-Impact Applications (Managed/Standard Backlash):

Mining Equipment: Large dragline excavators.

Forestry Equipment: Harvester heads.

How to Select Backlash for Slew Drives: A Comprehensive Step-by-Step Guide

Selecting the optimal backlash requires a systematic approach that balances theoretical requirements with practical constraints. Follow this detailed process to ensure your slew drive performs reliably throughout its service life.

Step 1: Define the Primary Performance Objective

Begin by identifying the non-negotiable requirement for your application. This will serve as your selection compass:

Is it Positioning Accuracy? (e.g., for automated welding or antenna pointing)

Is it Shock Load Absorption? (e.g., for excavators or demolition equipment)

Is it Maximum Service Life with Minimal Maintenance? (e.g., for remote solar trackers)

Your primary objective will heavily influence whether you prioritize low, standard, or specially managed backlash.

Step 2: Conduct a Detailed Load and Motion Analysis

Gather precise data on your operating conditions. This step is critical for accurate supplier consultation.

Load Profile Quantification:

Static Loads: Specify the constant axial, radial, and moment (tilt) loads.

Dynamic Loads: Estimate shock load magnitude, frequency, and direction. Consider using a load spectrum if available.

Load Torque: Calculate the maximum operational torque, including acceleration/deceleration torque and any external resistance.

Motion Profile Specification:

Speed Range: Specify minimum and maximum rotational speeds.

Duty Cycle: Detail operating hours per day, starts/stops per hour, and percentage of time under full load.

Reversal Frequency: Note how often and how rapidly direction changes occur.

Step 3: Assess Environmental and Operational Influences

Environmental factors directly affect how backlash behaves over time.

Temperature Extremes:

Determine the full operational temperature range. Remember that internal gearbox temperatures can be 20-40°C higher than ambient.

Rule of Thumb: For applications operating below -20°C or above 80°C, discuss thermal compensation strategies with your supplier. You may need special lubricants or adjusted initial backlash.

Contamination Risk:

Rate your environment on a scale from clean (lab) to severe (quarry, offshore).

For high-contamination environments, prioritize drives with multi-stage sealing (labyrinth seals combined with grease purging). In such cases, a slightly larger initial backlash may be specified to account for faster, but more predictable, abrasive wear.

Step 4: Apply Industry-Specific Rules of Thumb

While each application is unique, these guidelines provide a starting point:

Precision Machinery: Target backlash of ≤5 arcminutes or as specified by the positioning system's angular resolution.

General Industrial Machinery: Backlash of 8-15 arcminutes is typical for cranes, material rotators, and heavy-duty positioners.

High-Impact Applications: Backlash may be designed in the range of 15-25 arcminutes to cushion shock loads, with a focus on robust gear tooth geometry over minimal play.

Step 5: Perform the "Worst-Case" Scenario Check

Before finalizing, model two critical scenarios to avoid failure:

The "Cold Start & High Load" Scenario: Will the contracted backlash at minimum temperature, combined with maximum load deformation, risk zero-clearance and cause binding? Solution: Ensure minimum operating backlash (after thermal/load effects) remains positive.

The "End-of-Life & High Temperature" Scenario: Will the increased backlash from wear, at maximum operating temperature, exceed the tolerance of your control system? Solution: Define the maximum allowable backlash and ensure the drive's maintenance interval and wear life align with it.

Step 6: Prototype Validation and Measurement

Whenever possible, validate your selection empirically:

Specify the Measurement Protocol: Agree with your supplier on how backlash will be measured (e.g., at the output flange with a specified input torque).

Test Under Real Conditions: If feasible, test a prototype under actual or simulated loads and temperature cycles. Monitor backlash change over a representative duty cycle.

Step 7: Finalize with Technical Consultation

Present your findings from Steps 1-6 to a qualified slew drive engineer. A technical discussion should cover:

Lifecycle Cost Analysis: Compare the initial cost of a precision low-backlash drive versus the potential maintenance costs and downtime of a standard drive in your application.

Lubrication Strategy: Finalize the lubricant type and regreasing intervals based on your backlash selection and operating environment.

Acceptance Criteria: Clearly define the acceptable backlash range for incoming inspection and end-of-warranty checks.

Remember: Selecting backlash is an iterative process between your application needs and engineering realities. Documenting each step of this process not only leads to a better technical decision but also provides valuable records for future maintenance and redesign projects.

Custom Slew Drive Solutions by LyraDrive

LyraDrive is a professional one-stop slewing device manufacturer majored in design and development, customized production, sales and service on slewing bearings and slew drives.

The LyraDrive team has been deeply involved in the design, manufacturing and application of slewing drives, slewing bearings and worm gear drives for more than 15 years, majored in the design and manufacture worm gear slew drives, double worm slew drives and spur gear slew drives.

Our engineering team works directly with you to analyze your requirements—from load and precision needs to environmental conditions and space constraints. We don't just sell a product; we provide a tailored rotational solution. Whether you need a compact drive with ultra-low backlash for a scientific instrument or a rugged, high-capacity drive for a port crane, we can design and manufacture the optimal unit for you.

FAQ on Selecting Backlash for Slew Drives

Q1: Can backlash be adjusted or eliminated after installation?

A: In standard slew drives, backlash is set at the factory and is not field-adjustable. Some specialized designs allow for limited adjustment. "Eliminating" it entirely is not advisable as it leads to binding and premature failure. The goal is to specify the correct amount from the start.

Q2: Does backlash increase over time?

A: Yes, gradually. As the gear teeth and bearings wear through normal operation, backlash will naturally increase. Proper lubrication is the single most important factor in minimizing wear and stabilizing backlash over the drive's service life. Always follow the manufacturer's lubrication schedule and use the recommended grease.

Q3: How does LyraDrive ensure consistent backlash in its products?

A: As a specialist manufacturer of both slew drives and slewing bearings, we have complete control over the entire manufacturing process. Our integrated production allows for precise matching of worm gears to bearing gear teeth and strict quality control at every stage, ensuring the backlash specification you order is the one you receive—consistently.

Q4: I'm unsure about my exact backlash requirement. What should I do?

A: Contact us. Share your application details, performance goals, and any challenges. Our technical team's expertise is here to help you define the right specifications, including backlash, for a reliable and high-performing slew drive solution