Key Factors in High-Speed Slew Drive Selection

Selecting the right high-speed slew drive is a pivotal engineering decision that directly impacts the performance, efficiency, and longevity of your machinery. Unlike standard-speed drives, high-speed models operate under more demanding conditions, requiring a meticulous selection process that balances performance needs with durability and cost. This guide breaks down the essential factors to consider, helping you make an informed choice for your specific application.

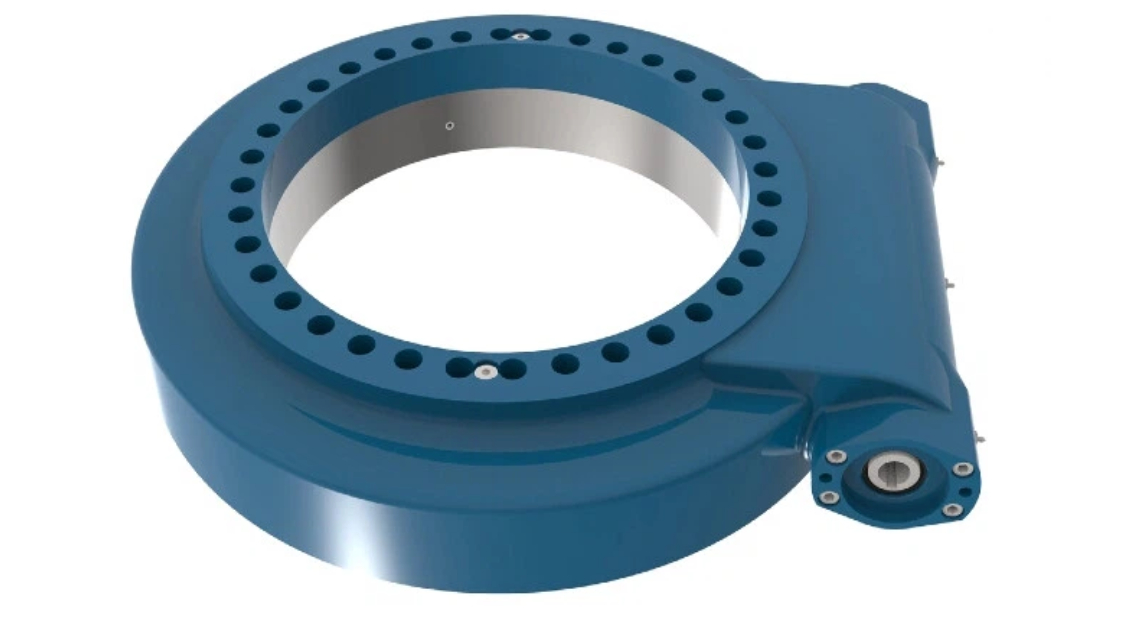

What is Slew Drive?

A slew drive is a compact, highly integrated power transmission component that provides controlled rotational movement. It combines a high-precision slewing bearing with a worm gear drive mechanism in a single, sealed housing. This integration allows it to handle significant axial, radial, and moment loads while delivering high reduction ratios, precise positioning, and often a self-locking feature. Slew drives are the essential "joints" that enable heavy equipment to rotate, pivot, and tilt with remarkable strength and control.

How Does a Slew Drive Work?

The operation of a slew drive is elegantly simple yet highly effective. Its core mechanism is a worm gear set. An input shaft, driven by an electric, hydraulic, or pneumatic motor, rotates the worm (a screw-like gear). This worm meshes with the teeth of the worm wheel, which is directly connected to the output flange of the drive. As the worm turns, it drives the worm wheel, converting the motor's high-speed, low-torque rotation into a powerful, low-speed, high-torque output—or, in the case of high-speed models, a faster output with optimized torque. The integrated slewing bearing supports the entire structure, managing the complex loads during rotation. This efficient design provides a robust solution for applications requiring reliable rotational motion.

The Characteristics of High-Speed Slew Drives

High-speed slew drives are engineered specifically for applications demanding rapid rotational speeds, typically ranging from several tens to over a hundred revolutions per minute at the output. Key characteristics that differentiate them from standard drives include:

Optimized Gear Geometry: The worm and worm wheel are designed with specialized tooth profiles and precision machining to minimize friction and heat generation at elevated speeds.

Advanced Thermal Management: They often incorporate features like aluminum housings (for better heat dissipation) and high-performance lubrication systems to manage the increased operational heat.

High-Precision Components: Utilizing high-grade slewing bearings (like cross roller or three-row roller bearings) and gears ensures smooth, low-vibration operation essential for high-speed performance.

Robust Sealing: Enhanced sealing systems are critical to contain special lubricants and prevent contamination from entering the drive, which is more challenging under centrifugal forces at high speeds.

Dynamic Balancing: Critical rotating assemblies are dynamically balanced to minimize vibration, leading to quieter operation, reduced wear, and longer service life.

The Applications of High-Speed Slew Drives

These specialized drives are indispensable in industries where speed and precision are critical:

Solar Tracking Systems: For rapidly and precisely adjusting the angle of photovoltaic panels or concentrated solar power (CSP) heliostats to follow the sun's path.

Automated Machinery & Robotics: In assembly lines, packaging machines, and robotic arms where fast indexing, pivoting, or part positioning is required.

Radar and Surveillance Antennas: Enabling the fast and smooth 360-degree rotation of communication and surveillance antennas.

Material Handling: In high-speed rotary tables, indexers, and automated guided vehicle (AGV) rotation modules.

Test and Simulation Equipment: Where rapid movement and precise angular positioning are needed for testing and simulation platforms.

Key Factors and How to Select High-Speed Slew Drives

Selecting the optimal high-speed slew drive requires a thorough analysis of your application. Here are the key factors, distilled from industry expertise:

Performance Requirements:

Torque & Speed: Precisely define the required output torque and speed. A drive must be capable of handling both the input power and delivering the necessary output without overload.

Load Profile: Analyze the load type—whether it's steady, cyclic, or involves shock loads. This affects the drive's required fatigue strength and safety factor.

Duty Cycle: Determine if operation is continuous, intermittent, or involves frequent start-stop reversals. This impacts thermal design and lubrication selection.

Environmental Conditions:

Operating Temperature: High speeds generate heat. The drive must be rated for your ambient and operational temperature range to prevent lubricant breakdown and component failure.

Contaminants: Exposure to dust, moisture, or chemicals necessitates drives with superior sealing (IP ratings) and possibly corrosion-resistant materials.

Installation Space: Consider spatial constraints, mounting orientation, and accessibility for maintenance.

Design & Material Considerations:

Housing Material: Cast iron offers supreme strength and dampening for heavy-duty, high-vibration settings. Aluminum provides excellent heat dissipation and weight savings for dynamic applications.

Gear Material: High-strength alloy steels like 42CrMo are essential for their superior wear resistance and ability to withstand the high contact stresses of fast-moving gears.

Bearing & Lubrication: High-precision bearings (e.g., deep groove ball or cylindrical roller bearings) are standard. Specialized high-speed grease or oil lubrication systems are non-negotiable for reducing friction and managing heat.

Maintenance & Lifecycle:

Choose a design that allows for easy access to seals and lubrication ports.

Consider the Total Cost of Ownership (TCO), which includes initial price, maintenance costs, energy efficiency, and expected service life. A higher-quality drive often has a lower TCO.

Supplier Expertise:

Partner with a manufacturer with proven experience in high-speed applications. Their technical support is invaluable for selection, integration, and troubleshooting.

Evaluate their warranty, after-sales service, and availability of spare parts.

Custom high-speed Slew Drive Solutions by LyraDrive

At LyraDrive, our core strength lies in engineering customized swing drive solutions. We can supply high-speed slew drives to your exact specifications and provide a full range of after-sales services!

Our engineering team collaborates directly with you to understand the nuances of your application—from exceptional speed and load requirements to extreme environmental challenges and tight space constraints. We then tailor every aspect, from gear geometry and material selection to housing design and sealing solutions, creating a drive that delivers unmatched reliability and performance precisely where you need it.

FAQ on High-Speed Slew Drive Selection

Q1: Can I use a standard slew drive and just run it faster to achieve high speed?

A: No, this is not advisable. Standard drives are engineered for optimal performance at lower speeds. Operating them at high speeds can lead to excessive heat generation, accelerated wear, lubrication failure, and catastrophic breakdown due to unmanaged dynamic forces.

Q2: How critical is lubrication for a high-speed slew drive?

A: It is absolutely critical. Lubrication does more than reduce wear; in high-speed drives, it plays a vital role in heat dissipation. Using the wrong type or grade of lubricant is a leading cause of premature high-speed drive failure.

Q3: When should I consider a custom high-speed slew drive solution?

A: Consider a custom solution when facing: unique combination of high speed and high torque, extreme temperature ranges (-40°C to +80°C+), stringent size/weight limitations, need for specific mounting interfaces, or exposure to highly corrosive or abrasive environments.

Q4: Who is LyraDrive?

A: LyraDrive is a professional one-stop slewing device manufacturer majored in design and development, customized production, sales and service on slewing bearings and slewing drives. The LyraDrive team has been deeply involved in the design, manufacturing and application of slewing drives, slewing bearings and worm gear drives for more than 15 years, majored in the design and manufacture SE slew drives, WE slew drives, SP slew drives. We are dedicated to providing robust, innovative motion solutions for the most challenging industrial applications.