How to Improve the Load Capacity and Transmission Efficiency of Worm Gears in Slew Drive?

What is Worm Gear Slew Drive?

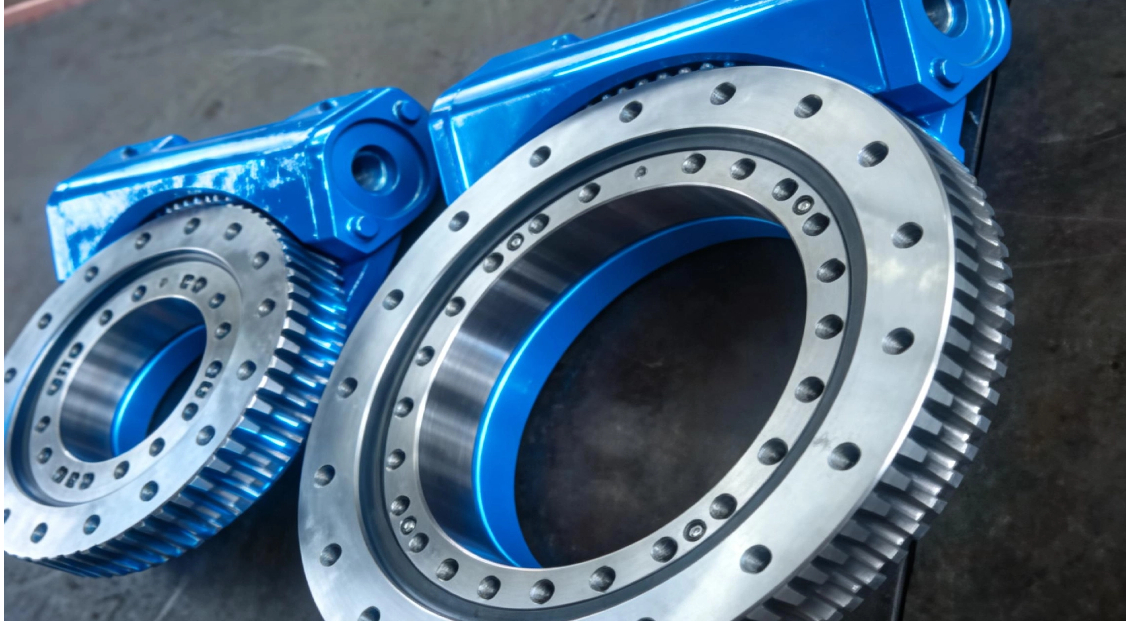

A worm gear slew drive is a high-performance slewing mechanism engineered to transmit power, deliver precise rotation, and maintain stable positioning in industrial and heavy-duty applications. At its core, it leverages a worm gear assembly—consisting of a worm (drive component) and a worm wheel (driven component)—to achieve exceptional torque output, controlled low-speed operation, and inherent self-locking capabilities, making it a preferred choice for scenarios requiring reliability and precision.

How exactly does it work?

The Worm: The Active "Driver"

The worm resembles a metal screw with helical grooves. It serves as the power input for the entire system. When a motor rotates the worm, it acts like a specialized screw turning.The Worm Gear: The Passive "Actuator"

The worm gear is a large helical gear, like a toothed ring. Its teeth mesh precisely with the grooves of the worm. The most crucial point here is that their interaction involves sliding friction, not rolling friction. Imagine the worm's threads "pushing" the worm gear's teeth to move them bit by bit.The Bearings: The Robust "Support"

The bearings are the unsung heroes of this system. They are typically mounted on both the inner and outer sides of the worm gear (i.e., within the drive housing) and perform two vital tasks:Supporting the Load: The weight and force of the entire rotating load (such as a crane boom or solar panel frame) are ultimately transferred through the worm gear to the bearings. The bearings allow the worm gear to rotate smoothly and steadily, preventing it from jamming or creating severe friction.

Counteracting Reaction Forces: When the worm pushes against the worm gear, significant radial and axial forces are generated. High-quality bearings (such as tapered roller bearings or crossed roller bearings) effectively "absorb" these forces, ensuring that the worm and worm gear remain in correct meshing alignment without shifting or loosening. Without the robust support of the bearings, this system would quickly fail under high loads.

Workflow and Logic:

Engagement and Transmission: The motor starts, rotating the worm. Due to the helix angle of the worm, its threaded "ramp" slides into and pushes the teeth of the worm gear. Because the worm must rotate many times to advance the worm gear by one tooth, this achieves a high reduction ratio (e.g., the worm rotates 40 times for the worm gear to rotate once). This reduction means speed decreases, but torque (rotational force) is amplified by the same factor. This is the fundamental principle behind its ability to produce "heavy-duty" power.

Self-Locking and Holding: This is the most unique and critical feature of worm gear transmission. Due to the shallow helix angle of the worm, when power stops (the worm ceases to rotate), any force from the worm gear trying to drive the worm backward is "locked" by the high sliding friction between the two. It's similar to how a wedge, once driven into a gap, is difficult to remove. At this point, the role of the bearings becomes even more pronounced: they firmly support the locked worm gear and load, ensuring the entire system remains motionless without the need for an external brake. This self-locking is a purely mechanical, absolutely reliable safety feature.

Energy Conversion and Loss: This system is not a perfect energy converter. Because the interaction between the worm and worm gear involves sliding friction, some of the input energy is converted into heat. This is the trade-off for achieving self-locking and is also why its transmission efficiency is typically lower than that of other gear types (such as planetary gears). Therefore, proper lubrication and heat dissipation design are crucial for its longevity and performance.

These three components are tightly integrated, working together to achieve the core functions of speed reduction with torque increase, precise positioning, and safe self-locking. This makes the worm gear slew drive the preferred transmission solution for many heavy-duty and precision applications

The Features of Worm Gear Slew Drive

Worm gear slew drives are renowned for several distinct features. They offer an exceptionally high torque output relative to their size. Their inherent self-locking capability ensures safety and stability by preventing reverse movement. The design is compact and integrates easily into machinery, saving space. They provide high shock load resistance and ensure smooth, low-vibration operation with minimal backlash when precision-manufactured. Furthermore, they are versatile and can be configured in various mounting orientations to suit different mechanical layouts.

Application of Worm Gear Slew Drive

Thanks to their strength and precision, worm gear slew drives are indispensable across many industries.

Renewable Energy Sector

In the renewable energy field, worm gear slew drives are critical components that ensure optimal energy capture and system safety. Solar tracking systems extensively use slew drives to enable photovoltaic panels to follow the sun's path with high precision throughout the day. This continuous adjustment maximizes energy generation by up to 40% compared to fixed systems. In wind turbines, high-capacity slew drives perform two vital functions: they rotate the entire nacelle (yaw control) to face incoming winds and adjust the blade angles (pitch control) to regulate power output and protect the turbine during storms. Their self-locking nature is crucial here, holding massive structures securely against strong, variable wind forces without slippage.

Construction and Heavy Machinery

The construction industry relies heavily on the immense torque and robust holding power of slew drives. They form the core rotational mechanism in the booms of mobile cranes, enabling smooth and controlled lifting and positioning of heavy loads. Excavators utilize them for precise 360-degree swing of the upper structure (house), allowing the machine to dig and dump material efficiently. Concrete pump trucks employ slew drives to rotate the distribution boom accurately, placing concrete at the required location across a construction site. Their compact design and ability to handle severe shock loads make them ideal for the rugged conditions of construction sites.

Industrial Automation and Material Handling

Within factories and warehouses, worm gear slew drives provide reliable motion control for automation. They are integral to rotary index tables used in assembly lines, where they position workpieces with repeatable accuracy for machining or assembly operations. Robotic arms and welding positioners use compact slew drives for precise rotational axes. In material handling, they power the rotation of heavy-duty turntables, drum rollers, and large conveyor systems, facilitating efficient sorting, palletizing, and transfer of goods. Their combination of precision, compactness, and self-locking enhances both the safety and efficiency of automated processes.

Aerospace, Defense, and Communications

This sector demands extreme precision and unwavering reliability, which worm gear slew drives consistently deliver. They are fundamental in positioning radar dishes for air traffic control, weather monitoring, and military surveillance, ensuring accurate signal transmission and reception regardless of environmental conditions. Similarly, they rotate satellite communication antennas and large radio telescopes to track satellites or celestial objects across the sky with minute accuracy. In military applications, they are used in missile launch systems, optical targeting platforms, and armored vehicle turrets, where fail-safe holding and precise movement are paramount.

Specialized and Access Equipment

Beyond major industries, slew drives enable functionality in numerous specialized machines. Aerial work platforms and scissor lifts use them to safely rotate the work basket, allowing operators to reach work areas without repositioning the entire vehicle. In entertainment, they control the slow, stable rotation of large stage platforms and Ferris wheels. Agricultural machinery, such as large irrigation systems (center pivots), employs them for controlled rotation over vast fields. Their versatility, durability, and controlled power output make them the go-to solution for any application requiring slow-speed, high-torque, and reliable rotational movement.

Advantages and Disadvantages of Worm Gear Slew Drives

Worm gear slew drives are widely chosen for many demanding applications, but like any mechanical component, they present a unique set of advantages and limitations. Understanding this balance is crucial for proper selection and system design.

Advantages:

High Torque and Compact Design: They provide a very high torque multiplication in a single, compact stage, allowing for powerful rotational output from a relatively small package. This saves significant space and weight in machinery.

Self-Locking/Self-Braking: The inherent friction in the worm-to-gear mesh typically prevents back-driving. This means the drive can hold a load securely in a stationary position without the need for an external brake, enhancing safety and simplifying system design.

Smooth and Quiet Operation: The sliding, progressive engagement of the gear teeth results in very smooth and relatively quiet power transmission, which is beneficial in applications like antenna positioning or medical equipment.

High Shock Load Resistance: The robust gear design and large contact area allow these drives to absorb and withstand sudden impact loads, making them ideal for construction and heavy-duty machinery.

Large Reduction Ratios: They can achieve very high gear reduction ratios in a single step, effectively converting high input speed into very low output speed with high torque.

Disadvantages:

Lower Transmission Efficiency: Due to the predominant sliding friction between the worm and gear teeth, worm drives are generally less efficient than other gear types like helical or planetary gears. A significant portion of input energy is lost as heat, especially in single-start designs.

Heat Generation: The sliding friction that causes efficiency loss also generates considerable heat. This necessitates careful thermal management through proper lubrication, material selection, and sometimes external cooling in high-power or continuous-duty applications.

Limited High-Speed Capability: The friction and heat generation make them less suitable for very high-speed input applications. They are primarily designed for low-to-moderate input speeds with high-torque output.

Potential for Wear: The sliding contact can lead to wear over time, particularly if lubrication is inadequate or loads are misaligned. The softer worm gear material (often bronze) is typically the sacrificial component.

Typically Non-Reversible: While the self-locking feature is an advantage for holding, it means the system cannot be back-driven to use the output load as a means of driving the input shaft, which limits certain regenerative or manual override functionalities.

In summary, worm gear slew drives excel in applications where high torque, compact size, self-locking safety, and smooth operation are paramount, and where some efficiency loss is an acceptable trade-off. They are less ideal for applications requiring very high efficiency, high-speed operation, or reversible back-driving capability.

How to Improve the Load Capacity and Transmission Efficiency of Worm Gears in Slew Drives?

Given the inherent efficiency challenge highlighted in the disadvantages, enhancing both load capacity and transmission efficiency becomes crucial for optimizing slew drive performance, longevity, and expanding their application range. Here are key strategies based on design, material, and maintenance:

Material Selection and Heat Treatment: Using high-strength materials is fundamental. The worm is typically made from hardened alloy steel (e.g., 20CrMnTi) carburized and quenched to achieve a hard, wear-resistant surface. The worm gear is often made from durable bronze (e.g., aluminum bronze, tin bronze) or high-strength ductile iron. Proper heat treatment significantly increases surface hardness, fatigue strength, and load-bearing capacity, directly combating wear and extending life.

Optimized Gear Design and Precision Manufacturing: Implementing an optimized tooth profile, such as an enveloping (hourglass) worm design, increases the contact area between the worm and gear teeth. This distributes stress more evenly, boosting load capacity. Precision grinding of the worm after heat treatment ensures an accurate tooth profile and a smooth surface finish, which drastically reduces sliding friction losses, minimizes wear, and is one of the most effective ways to improve transmission efficiency.

Advanced Lubrication: Using high-performance, extreme-pressure (EP) lubricants formulated for worm gears is essential to address heat and wear. The right lubricant forms a protective film between the metal surfaces, reducing friction and heat generation. For demanding applications, implementing a sealed, circulating oil lubrication system can further enhance cooling, flush away wear particles, and maintain consistent lubrication, thereby improving efficiency and service life.

Optimal Gear Mesh Adjustment: Properly setting the backlash and ensuring precise alignment during assembly are critical. Correct backlash prevents binding under load while minimizing free play. Perfect alignment ensures the load is distributed uniformly across the tooth face, preventing premature wear and localized stress concentrations, which in turn maintains high efficiency and load capacity.

Surface Engineering Techniques: Applying advanced surface coatings, such as phosphating, nitriding, or specialized low-friction coatings (e.g., PTFE-based), can further reduce the coefficient of friction. Lower friction directly translates to higher transmission efficiency, less heat generation, and reduced energy loss.

Integrated Design and Stiffness: Designing a rigid housing and robust supporting bearings is vital. A stiff structure prevents deflection under heavy loads, maintaining the correct gear mesh alignment. This prevents misalignment-induced wear and inefficiency, ensuring that the designed load capacity and efficiency are achieved in real-world conditions.

LyraDrive Provides Effective Solutions for Your Slewing Drive Needs

LyraDrive specializes in engineering high-performance slew drives that incorporate these improvement principles. By utilizing premium materials, precision manufacturing processes like gear grinding, advanced lubrication solutions, and optimized design configurations, LyraDrive products are built to deliver superior load capacity, enhanced transmission efficiency, and long-term reliability for the most challenging applications, effectively mitigating the traditional disadvantages of worm gear systems.

FAQ of Worm Gear Slew Drive

Q: What is the self-locking feature?

A: It means the worm can easily turn the gear, but the gear cannot turn the worm due to the friction angle, acting as a built-in brake to hold loads securely.

Q: Can slew drives be used in both horizontal and vertical axes?

A: Yes, their compact and versatile design allows for mounting in multiple orientations to suit the specific rotation axis of the application.

Q: How do I maintain a worm gear slew drive?

A: Regular maintenance primarily involves checking and changing the lubricant according to the manufacturer's schedule, monitoring for leaks, and checking for excessive backlash or noise, which indicate wear.

Q: What affects the efficiency of a worm gear set?

A: The primary factors are the gear design (lead angle, profile), surface finish/smoothness, material combination, quality of lubrication, and alignment during assembly.

Q: Are high-efficiency worm gears still self-locking?

A: There is a trade-off. Standard single-start worms with a low lead angle offer strong self-locking. High-efficiency designs (e.g., multi-start worms with a larger lead angle) improve efficiency but may reduce or eliminate the self-locking effect. The design must be chosen based on the application's priority.